Aluminum phosphate coated silicon dioxide flame retardant and preparation method thereof, and flame-retardant epoxy resin composite material and preparation method thereof

A technology of silica and epoxy resin, which is applied in the field of flame retardant materials, can solve the problems of harsh production conditions of phosphorus-containing monomers, deterioration of dielectric properties and mechanical properties of composite materials, and complex preparation processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention further provides a method for preparing an aluminum phosphate-coated silica flame retardant described in the above technical scheme, comprising the following steps:

[0029] To provide a silica dispersion solution; the pH of the silica dispersion is 1.5 ~ 2.5;

[0030]Aluminum hydroxide, phosphoric acid and water are mixed, neutralization reaction is carried out to give an aluminum phosphate solution; the mass ratio of aluminum hydroxide and phosphoric acid is 5 ~ 25: 40 ~ 180;

[0031] The silica dispersion and aluminum phosphate solution were mixed to give a mixed solution;

[0032] In the mixed solution drop by drop added alkali solution, co-precipitation, to obtain aluminum phosphate coated silica flame retardant.

[0033] The present invention provides a silica dispersion. In the present invention, the pH of the silica dispersion is preferably 2. In the present invention, the preparation method of the silica dispersion preferably comprises: mixin...

Embodiment 1

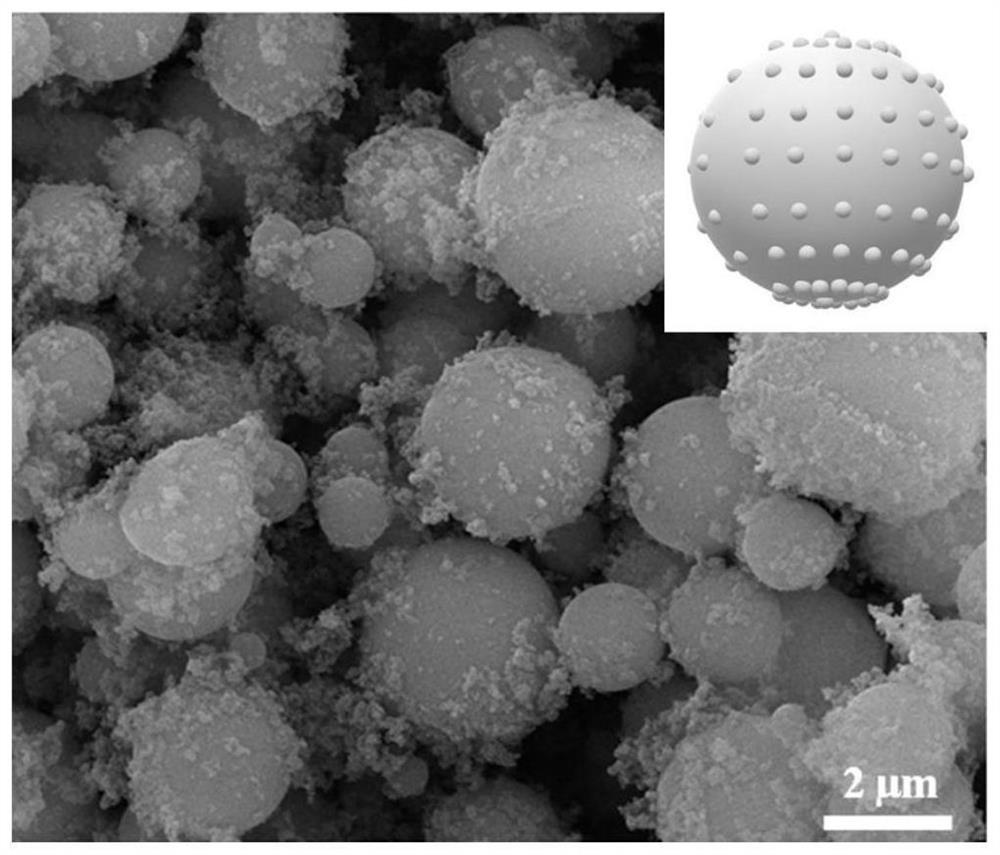

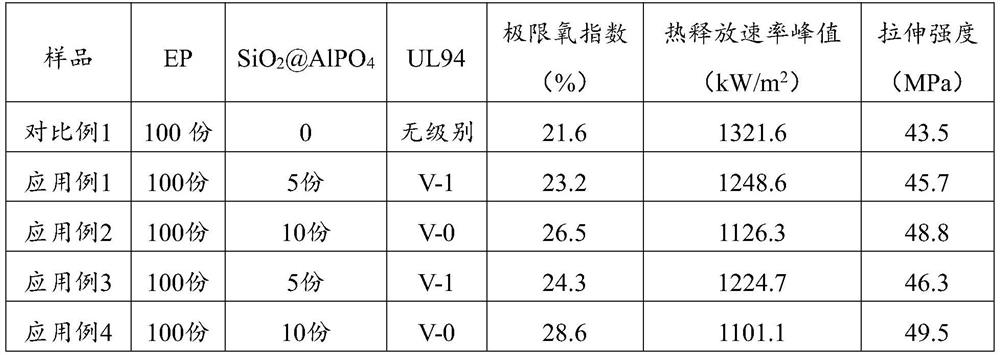

[0052] In terms of the number of parts by weight, put 100 parts of dried silica (average particle size of 2 μm) into a beaker, add pure water to give 6wt% of the aqueous silica solution, and add 37wt% of the hydrochloric acid to adjust the pH of the aqueous silica solution of 2 under the stirring state to obtain a silica dispersion solution; 5 parts Al(OH) 3 and 40 servings H 3 PO 4 Added to the beaker, add 20 parts of water for stirring and dissolving, to obtain an aluminum phosphate solution; the aluminum phosphate solution is slowly added to the silica dispersion, reacted at a stirring rate of 120rpm for 30min, and then added ammonia drop by drop (mass concentration of 27%) to adjust the pH of the solution to 5, co-precipitation, the resulting system was vacuum filtered, the resulting solid substance was washed with pure water, dried at 60 ° C, and aluminum phosphate coated with silica flame retardant (SiO) was obtained 2 @AlPO 4 )。

[0053]The aluminum phosphate-coated silica...

Embodiment 2

[0060] In terms of the number of parts by weight, 100 parts of dried silica (average particle size is 2 μm) into a beaker, pure water was added to give 6wt% aqueous silica solution, and 37wt% hydrochloric acid was added to adjust the pH of the aqueous silica solution under the stirring state to obtain a silica dispersion solution; 17 parts Al(OH) was added. 3 and 130 servings H 3 PO 4 Added to the beaker, add 100 parts of pure water for stirring and dissolving, to obtain an aluminum phosphate solution; the aluminum phosphate solution is slowly added to the silica dispersion, reacted at a stirring rate of 120rpm for 30min, and then added ammonia water drop by drop (mass concentration of 27%) to adjust the pH value of the solution to 5, co-precipitation, the resulting system for vacuum filtering, the resulting solid material is washed with pure water, dried at 60 ° C, and aluminum phosphate coated with silica flame retardant is obtained.

[0061] The aluminum phosphate-coated silica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak heat release rate | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com