Preparation method for high-strength flame0retardant antibacterial wood-plastic floor

A wood-plastic floor, high-strength technology, applied in the field of floor preparation, can solve problems such as difficult to take care of, low floor strength, flammability, etc., and achieve the effects of improving oxidation resistance, enhancing mechanical strength, and improving cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

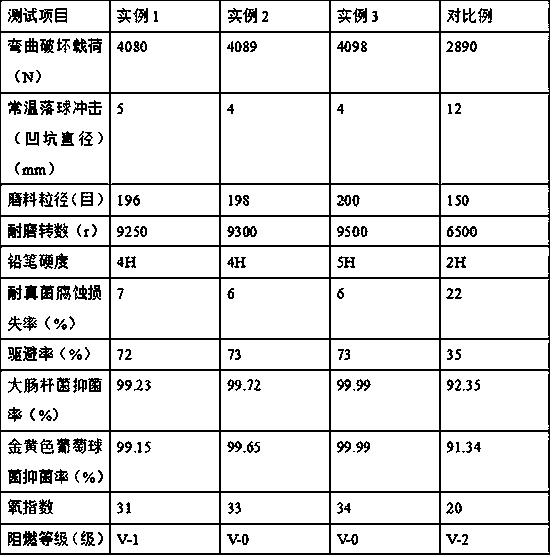

Examples

example 1

[0030] Put hydrotalcite and ceramic fragments of equal mass into a pulverizer to pulverize, pass through a 200-mesh sieve to obtain a mixed powder, mix the mixed powder with a mass fraction of 30% vinyltrimethoxysilane solution at a mass ratio of 1:3, Put it into a mixer and stir for 40min at a speed of 150r / min. After the stirring is completed, filter the cake to obtain the filter cake, and put the filter cake into an ultrasonic cleaner, and ultrasonically clean it at a frequency of 25kHz for 30min. After cleaning, put it into an oven. Dry at ℃ for 4 hours to obtain a modified solid, which is ready for use; put aloe vera, tea leaves, mugwort and grape skins of equal quality into a fermenter, and first leave the fermenter open for 2 days at a temperature of 20°C. After standing still, seal the fermenter, place the fermenter in a greenhouse at 35°C for sealed fermentation for 8 days, put the above-mentioned modified solid into the fermenter and continue to seal and ferment for 4...

example 2

[0032] Put hydrotalcite and ceramic fragments of equal mass into a pulverizer to pulverize, pass through a 200-mesh sieve to obtain a mixed powder, mix the mixed powder with a mass fraction of 35% vinyltrimethoxysilane solution at a mass ratio of 1:3, Put it into the mixer and stir at a speed of 170r / min for 50min. After the stirring is completed, filter the filter cake to obtain the filter cake, and put the filter cake into an ultrasonic cleaner, and ultrasonically clean it for 35min at a frequency of 27kHz. After cleaning, put it into an oven. Dry at ℃ for 4.5 hours to obtain a modified solid, which is ready for use; mix aloe vera, tea leaves, mugwort and grape skins of equal quality into a fermenter, and first leave the fermenter open for 2 days at a temperature of 22°C After standing still, seal the fermenter, place the fermenter in a greenhouse at 37°C for sealed fermentation for 9 days, put the above-mentioned modified solid into the fermenter and continue to seal and fer...

example 3

[0034] Put hydrotalcite and ceramic fragments of equal mass into a pulverizer to pulverize, pass through a 200-mesh sieve to obtain a mixed powder, mix the mixed powder with a mass fraction of 40% vinyltrimethoxysilane solution at a mass ratio of 1:3, Put it into a mixer and stir for 60min at a speed of 200r / min. After the stirring is completed, filter the cake to obtain the filter cake, and put the filter cake into an ultrasonic cleaner, and ultrasonically clean it at a frequency of 30kHz for 40min. Dry at ℃ for 5 hours to obtain a modified solid for later use; mix aloe vera, tea leaves, mugwort and grape skins of equal quality into a fermenter, and first leave the fermenter open for 3 days at a temperature of 25°C. After standing still, seal the fermenter, place the fermenter in a greenhouse at 40°C for sealed fermentation for 10 days, put the above-mentioned modified solid into the fermenter and continue to seal and ferment for 6 days, filter to obtain a solid-liquid mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com