Fiber and red mud co-modified epoxy resin composite material and preparation method thereof

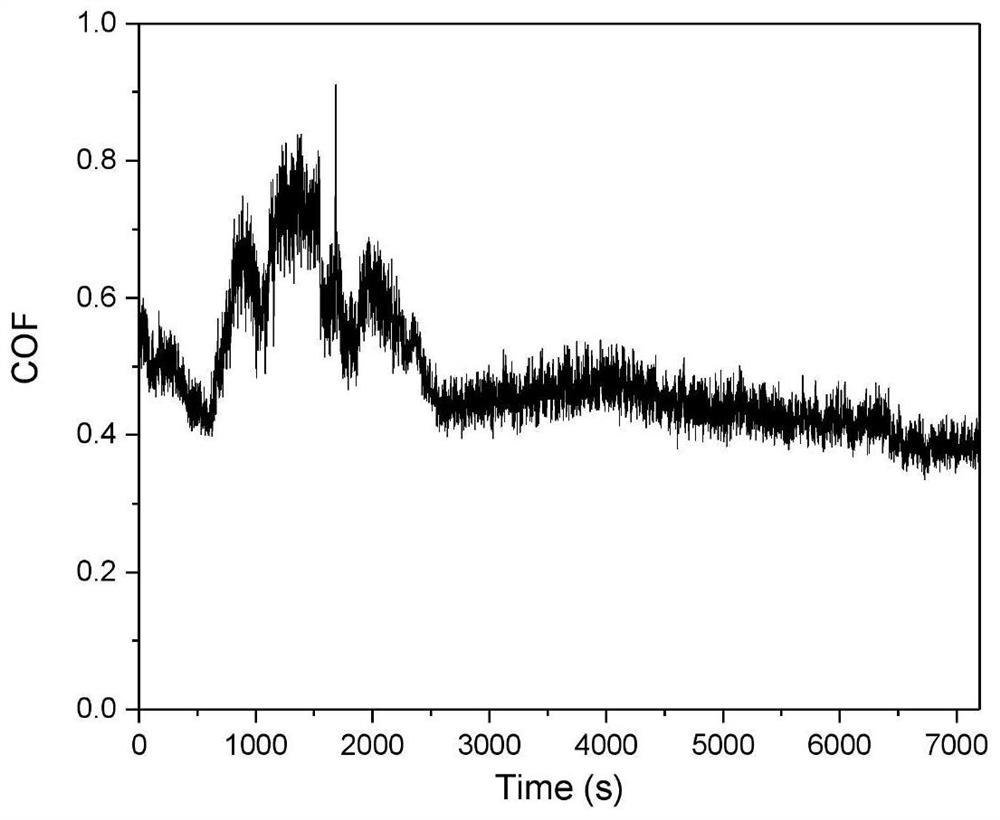

A technology of epoxy resin and composite materials, applied in the field of composite materials, can solve the problems of high cost and limit the application potential of modification methods, and achieve the effects of excellent toughness and strength, good mechanical properties and tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In the present invention, the preparation method of the coupling agent surface modified red mud material preferably includes the following steps:

[0031] Mixing red mud, organic acid and water, followed by dealkalization treatment and sedimentation separation treatment, to obtain dealkalization red mud;

[0032] Mix the dealkalized red mud, the first coupling agent, the second coupling agent with an organic solvent, and perform modification treatment to obtain a surface-modified red mud material of the coupling agent; the first coupling agent is a silane At least one of a coupling agent, an aluminate coupling agent and a titanate coupling agent, the second coupling agent is an amino coupling agent.

[0033] The invention mixes red mud, organic acid and water, and sequentially performs dealkalization treatment and sedimentation separation treatment to obtain dealkalized red mud. In the present invention, there is no special limitation on the source of the red mud (RM),...

Embodiment 1

[0077] 1. Preparation of dealkalized red mud

[0078] Add 160g of red mud (RM) into the solid pulverizer, carry out high-speed pulverization at 23000rpm, then pass the pulverized RM through a 100-mesh sieve, transfer the sieved RM into a round bottom flask, add 600mL distilled water and 20g Oxalic acid, under the condition of mechanical stirring at 1000rpm, control the reaction temperature of the oil bath to 80°C, and react for 120min to obtain the first RM dispersion; lower the temperature of the first RM dispersion to 60°C, and stir with a glass rod to make the red mud Disperse again to obtain the second RM dispersion; put the second RM dispersion for 3 minutes, take the upper yellow dispersion, and obtain the RM filter cake by suction filtration, and complete 1 settling separation; the lower solid obtained after standing The liquid mixture was diluted with water, and then the above-mentioned sedimentation and separation treatment steps were repeated, and the sedimentation a...

Embodiment 2

[0089] 1. Preparation of dealkalized red mud

[0090] With embodiment 1.

[0091] 2. Preparation of coupling agent surface modified RM

[0092] With embodiment 1.

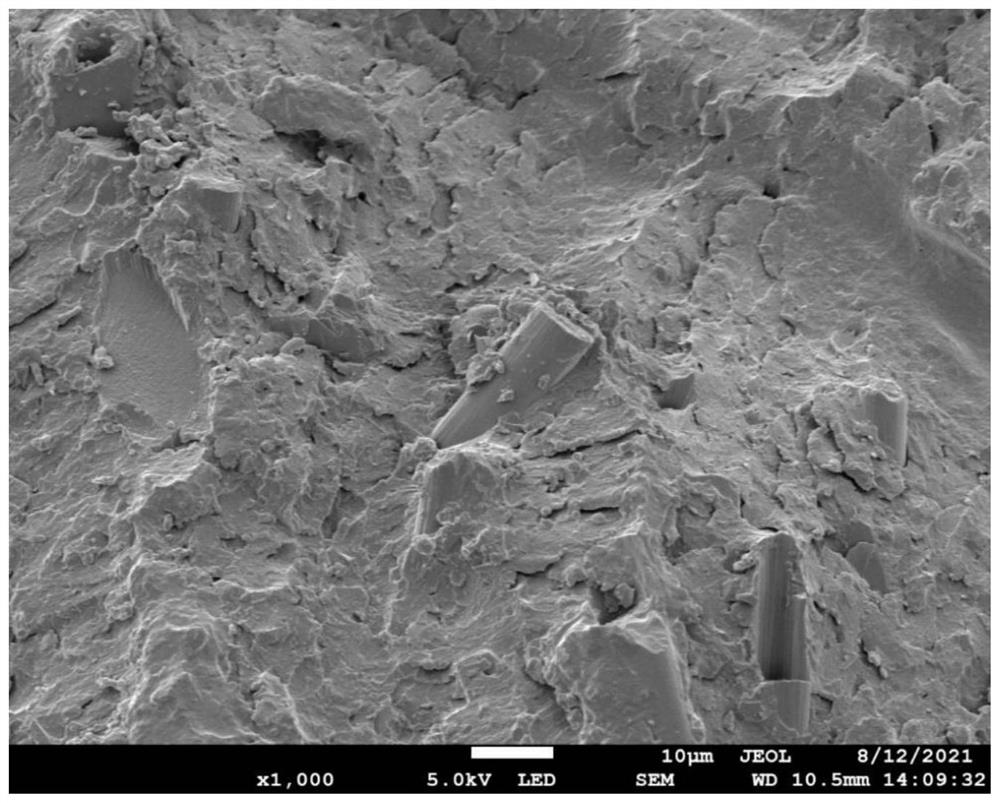

[0093] 3. Preparation of epoxy resin composite materials

[0094] 21.7g pulverized aramid fiber (SKF) and 36.6g coupling agent surface modified RM were pre-mixed with a high-speed pulverizer to obtain SKF / RM powder; 96g epoxy resin E-51 was weighed in a high-speed stirring tank, and added For the SKF / RM powder, select a polytetrafluoroethylene ball mill stirring head, control the reaction temperature to 70°C, adjust the stirring speed to 5000rpm, stir at a high speed for 10min, and degas the obtained system in a vacuum oven at 70°C for 10min to obtain dispersion treatment System; add 24.1g curing agent DDM and 0.2g silicone oil as defoamer to the dispersion treatment system, keep the reaction temperature at 70°C, adjust the stirring speed to 5000rpm, react for 10min, and place the obtained system in a vacuum ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com