Ultrahigh vacuum pump oil composition

A technology of ultra-high vacuum and composition, which is applied in the direction of lubricating composition and petroleum industry, etc. It can solve the problems that have not been involved in the application and the oil products that do not meet the requirements of ultra-high vacuum pump equipment, and achieve low saturated vapor pressure and good thermal stability. Good performance in high and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

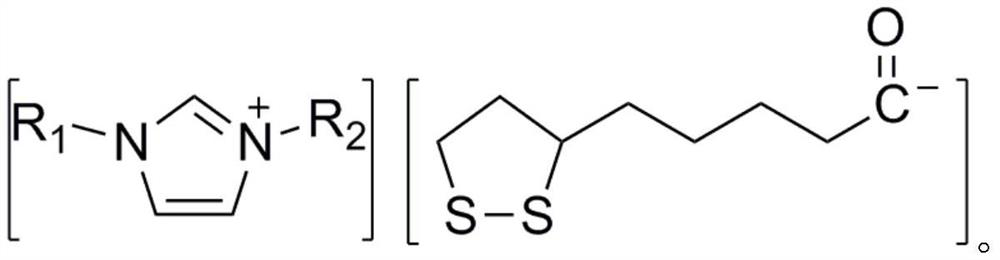

[0044] The components and contents of the ultra-high vacuum pump oil composition of the present embodiment are shown in the following table:

[0045]

[0046]

Embodiment 2

[0048] The components and contents of the ultra-high vacuum pump oil composition of the present embodiment are shown in the following table:

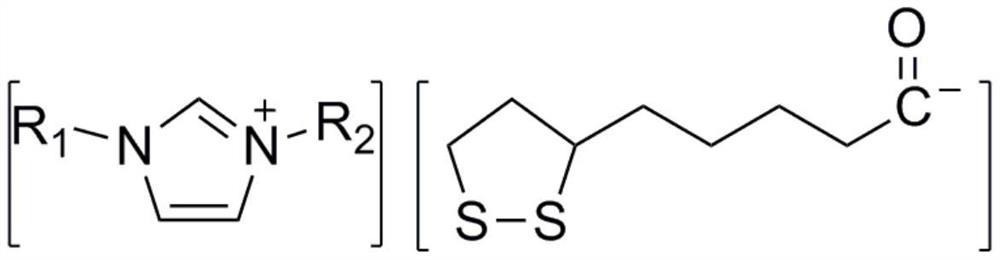

[0049] name Dosage (wt%) T204 0.30 Dialkyldithiocarbamate 0.50 Tris(2,4-di-tert-butylphenyl)phosphite 0.60 Alkylated phenyl-β-naphthylamine 0.20 Sorbitan monoglyceride 0.03 Polymer polyether 0.05 Polyethyleneimine alkoxylate 0.01 trimellitate 50 Alkyl imidazole lipoic acid ionic liquid 48.31

Embodiment 3

[0051] The components and contents of the ultra-high vacuum pump oil composition of the present embodiment are shown in the following table:

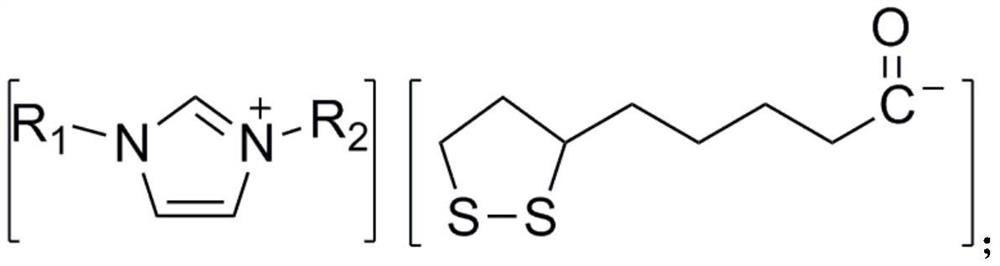

[0052] name Dosage (wt%) T203 0.40 Dialkyldithiocarbamate 0.40 Tris(2,4-di-tert-butylphenyl)phosphite 0.45 Alkylated phenyl-β-naphthylamine 0.15 Sorbitan monoglyceride 0.04 Polymer polyether 0.04 Polyethyleneimine alkoxylate 0.01 trimellitate 60 Alkyl imidazole lipoic acid ionic liquid 38.51

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com