Microbial capsule for valuable metal recovery and preparation method and application thereof

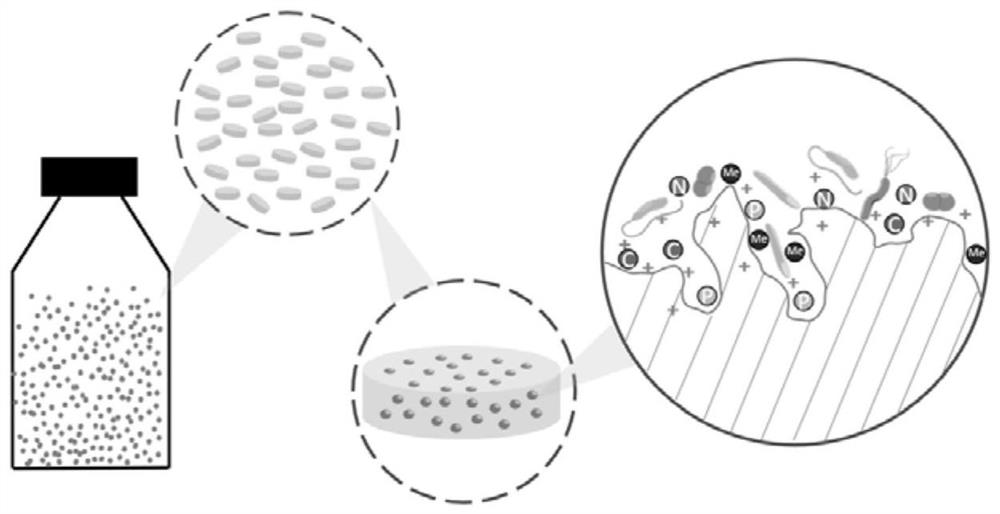

A technology of valuable metals and microorganisms, which is applied in the field of microbial capsules for recovery of valuable metals and its preparation, can solve problems such as the difficulty in recovering fly ash metals, and achieve the promotion of material exchange and information transmission, stable directional reproduction, and increased diversity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of microbial capsule that is used for valuable metal recovery, it makes through the following steps:

[0040] S1: Perform interlayer domain amplification and surface functionalization treatment on the carrier; the treatment specifically includes the following steps:

[0041] SS1: Mix kaolin and water at a material-to-liquid ratio of 9g:100mL to 1.3×10 5The energy of J is ultrasonically irradiated for 10 minutes, then the kaolin is filtered out and dried at 100°C for 10 minutes;

[0042] SS2: Put the kaolin treated by SS1 in a quartz tube, evacuate the helium, and heat it in a muffle furnace at 800°C for 30s;

[0043] SS3: Mix the modifier with the SS2-treated kaolin at a mass ratio of 1:22.5, and then immerse the mixture in 45wt% H 3 PO 4 Soak in the solution for 24 hours, then take out the kaolin and dry it at 100°C for 10 minutes to complete the treatment of the carrier; the modifier is mixed with dialkyl dimethyl quaternary ammonium salt (DHT21) and humic a...

Embodiment 2

[0054] A kind of microbial capsule that is used for valuable metal recovery, it makes through the following steps:

[0055] S1: Perform interlayer domain amplification and surface functionalization treatment on the carrier; the treatment specifically includes the following steps:

[0056] SS1: Mix montmorillonite and water at a ratio of 8g:100mL to liquid, and use 1.0×10 5 J energy ultrasonic radiation for 12min, then filter out the montmorillonite and dry at 120°C for 5min;

[0057] SS2: Place the montmorillonite treated with SS1 in a quartz tube, evacuate the helium, and heat it in a muffle furnace at 750°C for 40s;

[0058] SS3: Mix the modifier with the montmorillonite treated with SS2 at a mass ratio of 1:20, and then immerse the mixture in 45wt% H 3 PO 4 Soak in the solution for 24 hours, then take out the montmorillonite and dry it at 120°C for 5 minutes to complete the treatment of the carrier; the modifier is mixed with dialkyl dimethyl quaternary ammonium salt (DH...

Embodiment 3

[0069] A kind of microbial capsule that is used for valuable metal recovery, it makes through the following steps:

[0070] S1: Perform interlayer domain amplification and surface functionalization treatment on the carrier; the treatment specifically includes the following steps:

[0071] SS1: Mix kaolin and water at a ratio of 8g:100mL to liquid, and use 1.5×10 5The energy of J is ultrasonically irradiated for 8 minutes, then the kaolin is filtered out and dried at 90°C for 10 minutes;

[0072] SS2: Put the kaolin treated by SS1 in a quartz tube, evacuate the helium, and heat it in a muffle furnace at 850°C for 20s;

[0073] SS3: Mix the modifier with the SS2-treated kaolin at a mass ratio of 1:25, and then immerse the mixture in 45wt% H 3 PO 4 Soak in the solution for 24 hours, then take out the kaolin and dry it at 90°C for 10 minutes to complete the treatment of the carrier; the modifier is mixed with dialkyl dimethyl quaternary ammonium salt (DHT21) and humic acid in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com