Medical ultrasonic knife Ti7Al4Mo titanium alloy wire and preparation method thereof

A titanium alloy wire and ultrasonic knife technology, applied in metal material coating process, anatomical instruments, solid-state diffusion coating, etc., can solve problems such as broken knife, improve surface hardness, uniform heat distribution, and improve material structure and mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

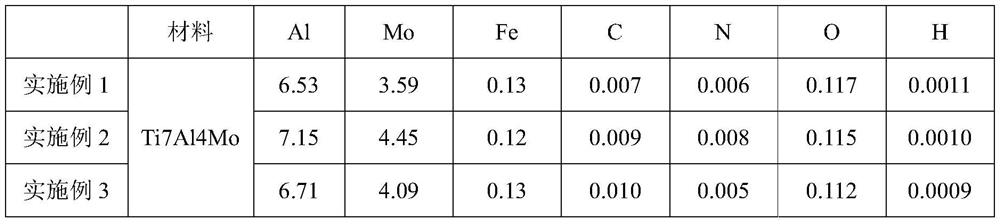

[0030] This embodiment provides a medical ultrasonic scalpel Ti7Al4Mo titanium alloy wire, in terms of mass percentage, including Al: 6.53%, Mo: 3.59%, Fe: 0.13%, C: 0.007%, N: 0.006%, O: 0.117 %, H: 0.0011%, the balance is titanium and unavoidable impurities.

[0031] Further, the raw materials are zero-order small particle sponge titanium, AlMoTi, Al beans, Fe nails and TiO 2 ; and adopt three times of vacuum self-consumption smelting technology to sample the ingot for composition testing and ultrasonic flaw detection to ensure that it meets the requirements.

[0032] Further, the tensile properties of the Ti7Al4Mo titanium alloy wire at room temperature are as follows: tensile strength Rm=1192MPa, elongation strength Rp0.2=1060MPa, elongation A=21.7%, reduction of area Z=46.5%.

[0033] Further, the sound velocity level of the Ti7Al4Mo titanium alloy wire is 6287m / s.

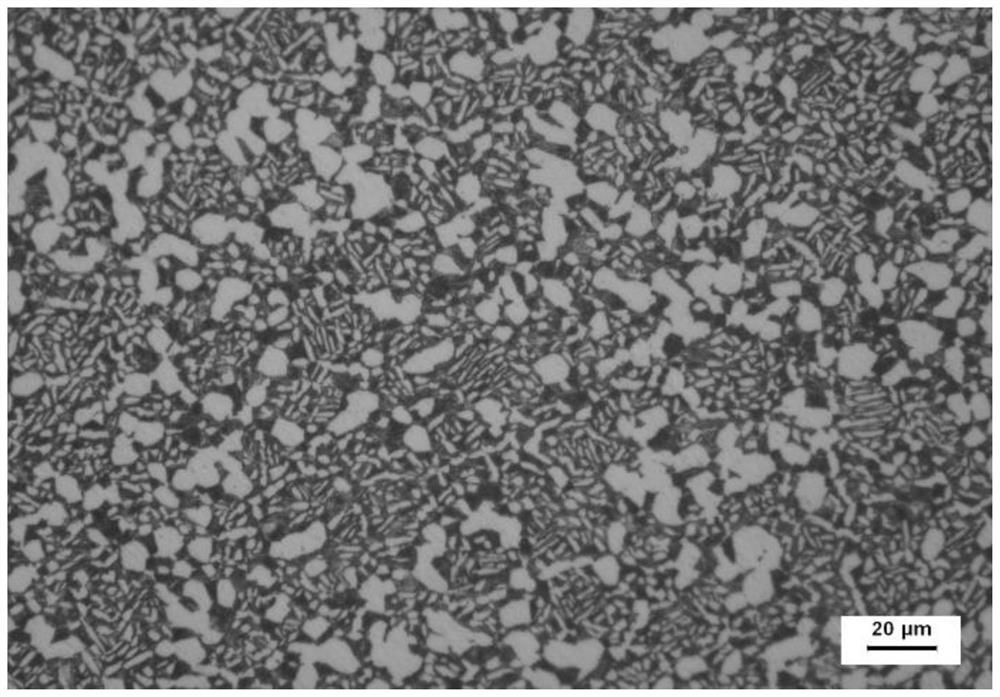

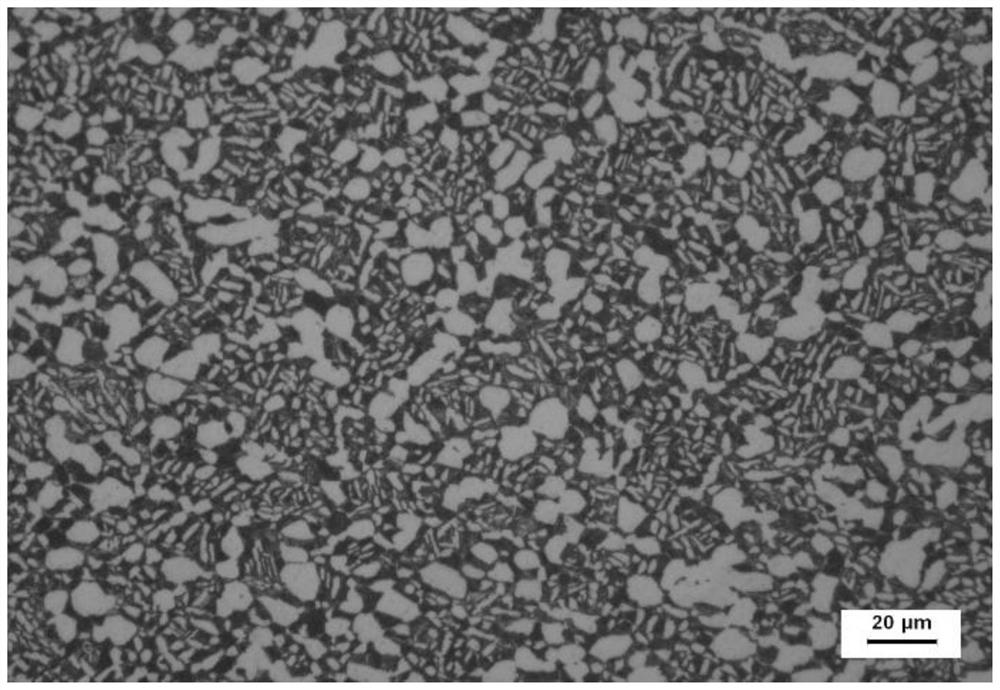

[0034] Further, the β-transition point of Ti7Al4Mo was measured to be 1010°C by metallographic method. ...

Embodiment 2

[0044]This embodiment provides a Ti7Al4Mo titanium alloy wire material for medical ultrasonic scalpel, including Al: 7.15%, Mo: 4.45%, Fe: 0.12%, C: 0.009%, N: 0.008%, O: 0.115 %, H: 0.0010%, the balance is titanium and unavoidable impurities.

[0045] Further, the raw materials are zero-order small particle sponge titanium, AlMoTi, Al beans, Fe nails and TiO 2 ; and adopt three times of vacuum self-consumption smelting technology to sample the ingot for composition testing and ultrasonic flaw detection to ensure that it meets the requirements.

[0046] Further, the tensile properties of the Ti7Al4Mo titanium alloy wire at room temperature are as follows: tensile strength Rm=1187MPa, elongation strength Rp0.2=1065MPa, elongation A=22.6%, reduction of area Z=45.7%.

[0047] Further, the sound velocity level of Ti7Al4Mo titanium alloy wire is 6295m / s.

[0048] Further, the β-transition point of Ti7Al4Mo was measured to be 1015°C by metallographic method.

[0049] In addition,...

Embodiment 3

[0058] This embodiment provides a Ti7Al4Mo titanium alloy wire material for a medical ultrasonic knife, including Al: 6.71%, Mo: 4.09%, Fe: 0.13%, C: 0.010%, N: 0.005%, O: 0.112 %, H: 0.0009%, the balance is titanium and unavoidable impurities.

[0059] Further, the raw materials are zero-order small particle sponge titanium, AlMoTi, Al beans, Fe nails and TiO 2 ; and adopt three times of vacuum self-consumption smelting technology to sample the ingot for composition testing and ultrasonic flaw detection to ensure that it meets the requirements.

[0060] Further, the tensile properties of the Ti7Al4Mo titanium alloy wire at room temperature are as follows: tensile strength Rm=1195MPa, elongation strength Rp0.2=1072MPa, elongation A=22.9%, reduction of area Z=46.3%.

[0061] Further, the sound velocity level of Ti7Al4Mo titanium alloy wire is 6292m / s.

[0062] Further, the β-transition point of Ti7Al4Mo was measured to be 1020°C by metallographic method.

[0063] In addition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com