HJT low-temperature conductive silver paste and preparation method thereof

A conductive silver paste, low temperature technology, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of insufficient fluidity, low curing temperature, and scattered silver powder. The effect of improving the morphology of printed lines and lines, reducing friction between powders and improving contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

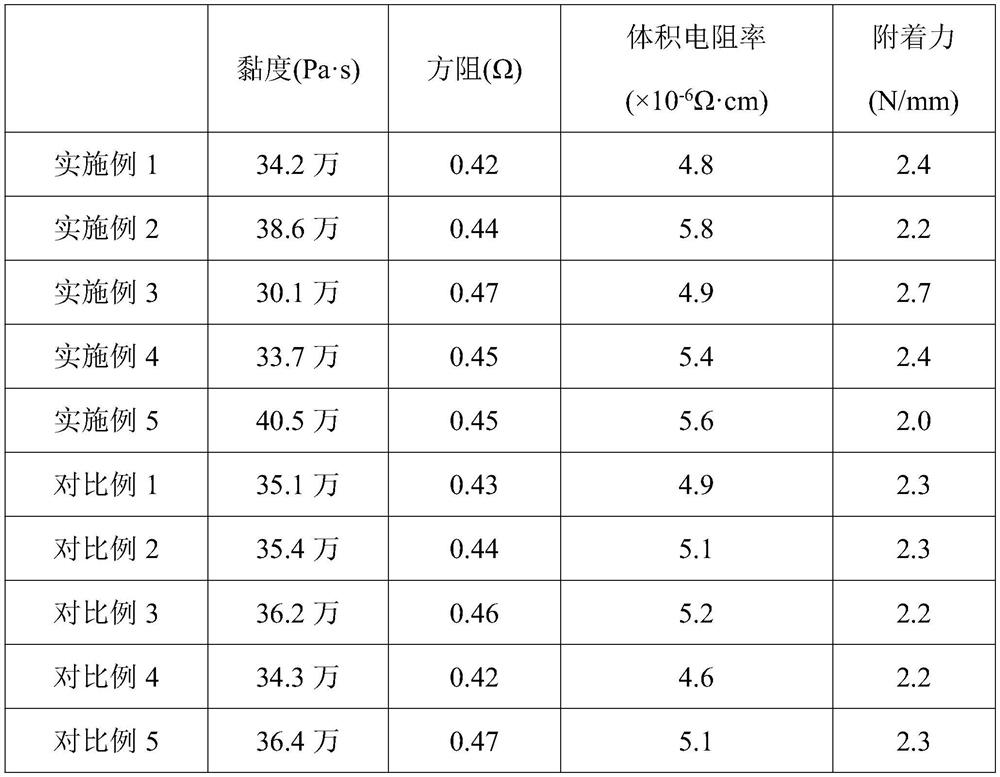

Examples

preparation example Construction

[0072] In another specific embodiment, the present invention provides a kind of preparation method of the low-temperature conductive silver paste of HJT as described above, and described preparation method comprises the following steps:

[0073] (1) Mix polyurethane resin, epoxy resin, solvent and curing agent, 1000-2000rpm / min, 1-3min first dispersion to obtain resin liquid;

[0074] (2) Mix the resin liquid and nano powder, carry out the second dispersion of 800-1500rpm / min, 2-4min in sequence, the ultrasonic dispersion of 3-6min and the third dispersion of 1000-2000rpm / min, 2-4min to obtain nano powder solution;

[0075] (3) mix described nano-powder solution and class A micro-powder, obtain semi-finished silver paste after the first rolling of 9-12 times;

[0076] (4) Mix the semi-finished silver paste, type B micron powder and additives, and obtain the low-temperature conductive silver paste after 9-12 second rolling, 400-600rpm / min, 10-15min fourth dispersion.

[0077]...

Embodiment 1

[0079] This embodiment provides a low-temperature conductive silver paste of HJT, the raw material components of the low-temperature conductive silver paste include by weight:

[0080] 3.5 parts of polyurethane prepolymer (relative molecular weight: 1700), 2 parts of diglycidyl 4,5-epoxycyclohexane-1,2-dicarboxylate, 3 parts of diethylene glycol butyl ether acetate, dicyandiamide 0.5 parts, 1 part of acrylate leveling agent (Bike, BYK-358N) and 90 parts of silver powder.

[0081] The silver powder includes micron powder and nano powder; the quality of the micron powder is 96% of the total mass of the silver powder; the quality of the nano powder is 4% of the total mass of the silver powder;

[0082] The micron powder includes flakes with a particle size of 3 μm and a tap density of 6.5 g / cm 3 Class A micron powder and spherical shape, particle size is 1.5μm, tap density is 4.3g / cm 3 The B class micron powder; The mass ratio of described A class micron powder and B class micr...

Embodiment 2

[0090] This embodiment provides a low-temperature conductive silver paste of HJT, the raw material components of the low-temperature conductive silver paste include by weight:

[0091] 2 parts of polyurethane prepolymer (relative molecular weight: 1300), 3 parts of 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate, 4 parts of diethylene glycol butyl ether, hexafluoroantimonic acid 0.2 parts of salt, 1.5 parts of polysiloxane defoamer (Bike, BYK-A530) and 95 parts of silver powder.

[0092] The silver powder includes micron powder and nano powder; the quality of the micron powder is 98% of the total mass of the silver powder; the quality of the nano powder is 2% of the total mass of the silver powder;

[0093] The micron powder includes flakes, the particle size is 1 μm, and the tap density is 6.9 g / cm 3 Class A micron powder and spherical shape, particle size is 0.5μm, tap density is 4.8g / cm 3 The B class micron powder; The mass ratio of described A class micron powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com