Efficient purification composite biological filler and preparation method thereof

A technology of biological fillers and composite microbial agents, applied in chemical instruments and methods, water treatment of special compounds, sustainable biological treatment, etc. Response efficiency cannot be guaranteed and other problems, to achieve the effect of improving biochemical reaction efficiency, strengthening anaerobic denitrification and denitrification and phosphorus removal synergistic biochemical process, and reducing the generation of ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

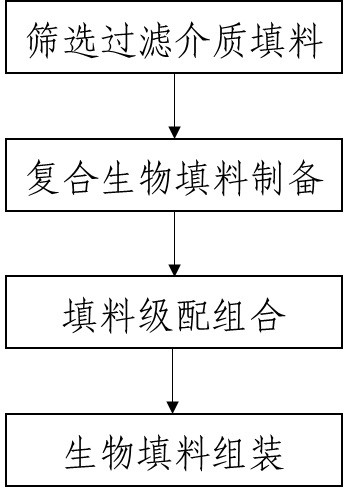

Method used

Image

Examples

Embodiment 1

[0035]The high-efficiency purification composite biological filler according to this embodiment includes a filter layer filler, a deep purification layer filler and a gravel layer filler arranged in sequence from top to bottom. The packing height of the filter layer is 600mm. The filling height of the deep purification layer is 250mm. The gravel layer packing height is 150mm. The filter layer filler is composed of quartz sand, corundum and diatomite biological ceramsite and arranged in sequence, wherein the ratio of each material is 60% of quartz sand, 25% of corundum and 15% of diatomite bioceramic. The deep purification layer filler contains composite biological filler made of quartz sand, zero-valent iron, activated carbon, composite microbial agent and porous slow-release biomass carbon source. The ratio of each material is: quartz sand 50%, zero-valent Iron 3%, activated carbon 40%, composite microbial agent 4%, porous slow-release biomass carbon source 3%.

[0036] In...

Embodiment 2

[0049] The high-efficiency purification composite biological filler according to this embodiment includes a filter layer filler, a deep purification layer filler and a gravel layer filler arranged in sequence from top to bottom. The packing height of the filter layer is 600mm. The filling height of the deep purification layer is 200mm. The gravel layer packing height is 200mm. The filter layer filler is composed of quartz sand, corundum and diatomite biological ceramsite, which are arranged in sequence, wherein the ratio of each material is 70% of quartz sand, 15% of corundum and 15% of diatomite bioceramic. The deep purification layer filler contains composite biological filler made of quartz sand, zero-valent iron, activated carbon, composite microbial agent and porous slow-release biomass carbon source. The ratio of each material is: quartz sand 50%, zero-valent 10% iron, 34% activated carbon, 3% compound microbial agent, 3% porous slow-release biomass carbon source.

[...

Embodiment 3

[0060] The high-efficiency purification composite biological filler according to this embodiment includes a filter layer filler, a deep purification layer filler and a gravel layer filler arranged in sequence from top to bottom. The packing height of the filter layer is 400mm. The filling height of the deep purification layer is 300mm. The gravel layer packing height is 150mm. The filter layer filler is composed of quartz sand, corundum, and diatomite bio-ceramic grain, which are arranged sequentially, wherein the ratio of each material is 80% of quartz sand, 12% of emery sand and 8% of diatomite bio-ceramic grain. The deep purification layer filler contains composite biological filler made of quartz sand, zero-valent iron, activated carbon, composite microbial agent and porous slow-release biomass carbon source. The ratio of each material is: quartz sand 60%, zero-valent Iron 5%, activated carbon 30%, composite microbial agent 3%, porous slow-release biomass carbon source 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com