Sulfur-based positive electrode material of all-solid-state battery and preparation method of sulfur-based positive electrode material

A technology for all-solid-state batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as poor interface contact and low electronic conductivity, and achieve improved diffusion kinetics, simple preparation methods, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

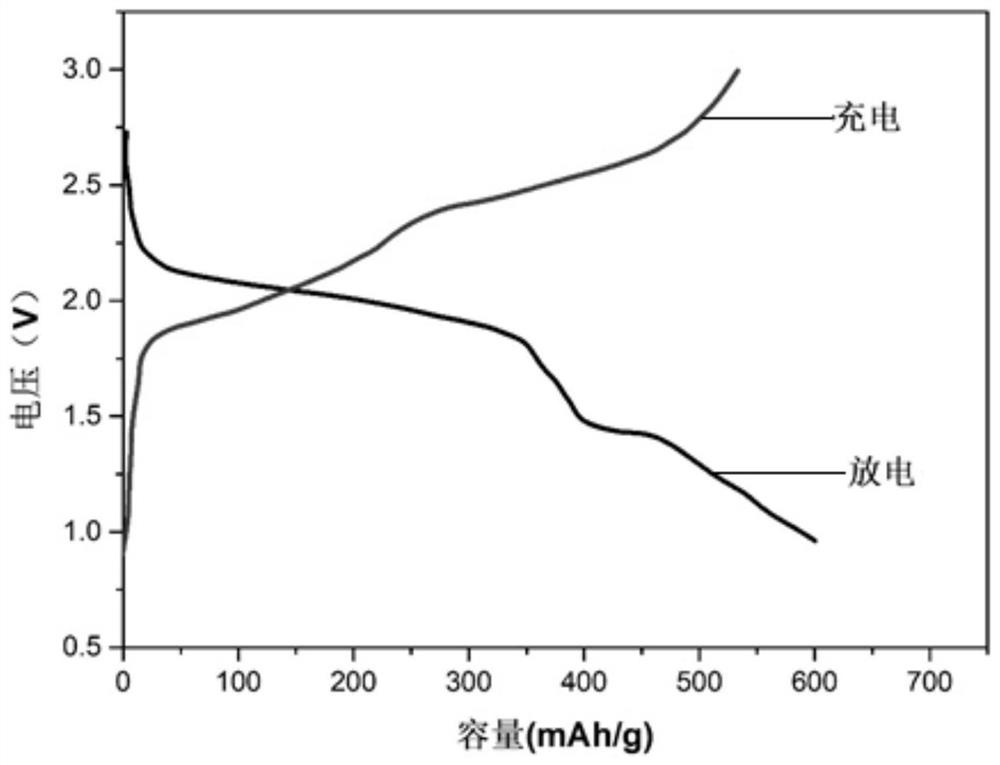

Embodiment 1

[0037] (1) Weigh 2g of polystyrene balls and add them into 60mL of nitric acid / sulfuric acid mixed solution for dispersion treatment. After centrifugal filtration, the precipitate and 2.5g of Na 2 S 2 o 4 Add 50ml of 2M NaOH solution for amination treatment. Wherein, the nitric acid / sulfuric acid mixed solution is obtained by mixing a nitric acid solution with a concentration of 2 mol / L and a sulfuric acid solution with a concentration of 2 mol / L at a volume ratio of 3:1.

[0038] (2) Mix elemental titanium, elemental aluminum, and titanium carbide at a molar ratio of 0.9:1:2.1, ball mill for 6 hours at a speed of 100r / min, and sinter the mixture at 1350°C under the protection of an argon atmosphere.

[0039] (3) Add the product obtained in step (2) into a solution formed by 1 g of lithium fluoride and 10 mL of 7M hydrochloric acid for chemical etching treatment, and react at 40° C. for 24 h.

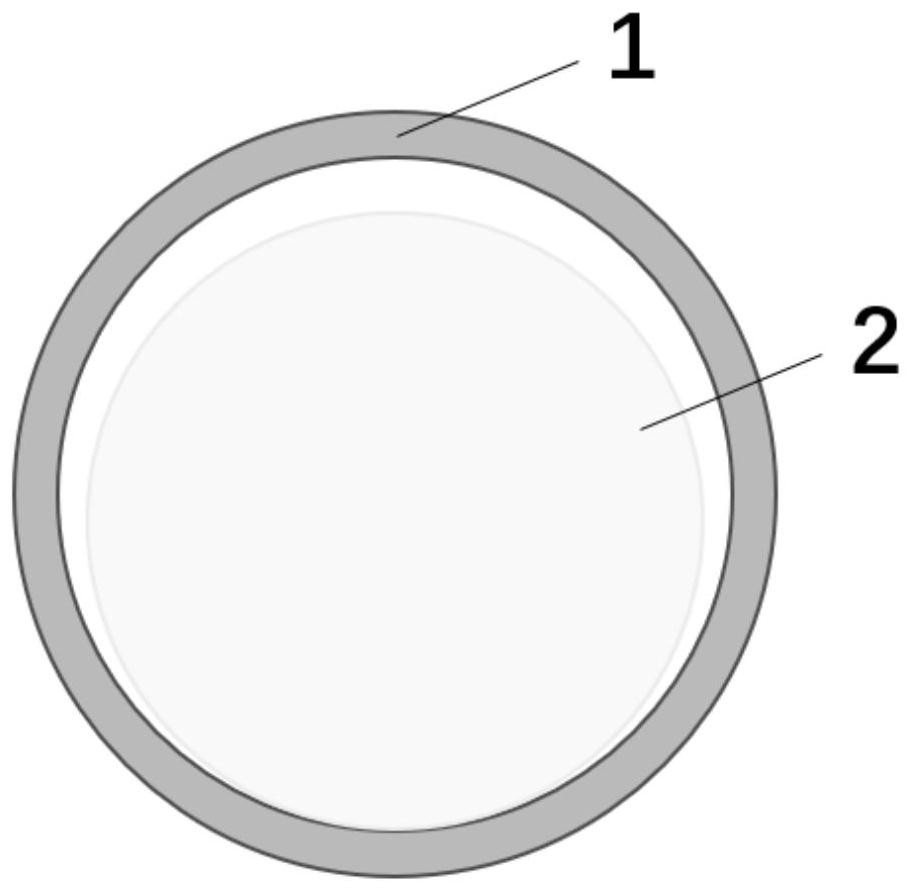

[0040] (4) 350 mg of polystyrene spheres with a radius of 1 μm and amination tre...

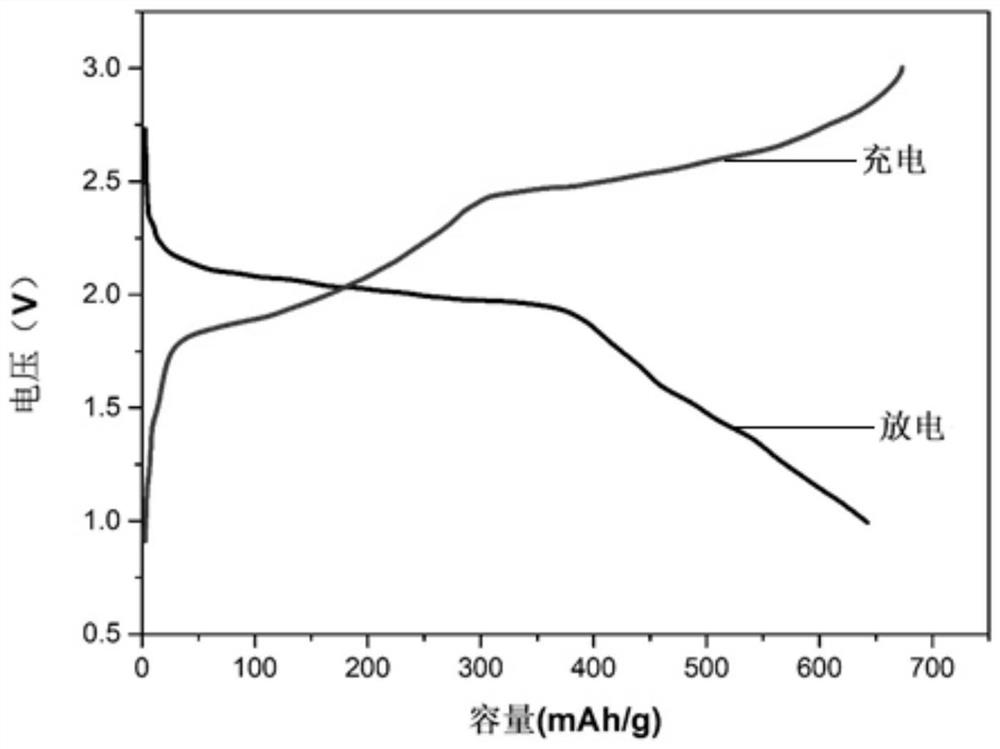

Embodiment 2

[0048] (1) Weigh 3g of polystyrene balls and add them into 80mL of nitric acid / sulfuric acid mixed solution for dispersion treatment. After centrifugal filtration, the precipitate and 3.7g of Na 2 S 2 o 4 Add 70ml of 2M NaOH solution for amination treatment.

[0049] (2) Mix elemental titanium, elemental aluminum, and titanium carbide at a molar ratio of 0.9:1:2.1, ball mill for 6 hours at a speed of 200r / min, and sinter the mixture at 1400°C under the protection of an argon atmosphere.

[0050] (3) Add the product of step (2) into a solution formed by 1 g of lithium fluoride and 10 mL of 9M hydrochloric acid for chemical etching treatment, and react at 50° C. for 24 h.

[0051] (4) 250 mg of polystyrene spheres with a radius of 750 μm and amination treatment in step (1) and 50 mg of MXene nanosheets obtained in step (3) were sequentially added to deionized water to obtain a mixed solution.

[0052] (5) Adjust the pH value of the mixed solution obtained in step (4) to 4, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com