Monochloroacetone production system

A production system, the technology of monochloroacetone, applied in organic chemistry, energy wastewater treatment, fractionation, etc., can solve the problems of unstable products, large environmental pollution, large amount of solid waste, etc., achieve stable color and reduce the amount of solid waste , improve the effect of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

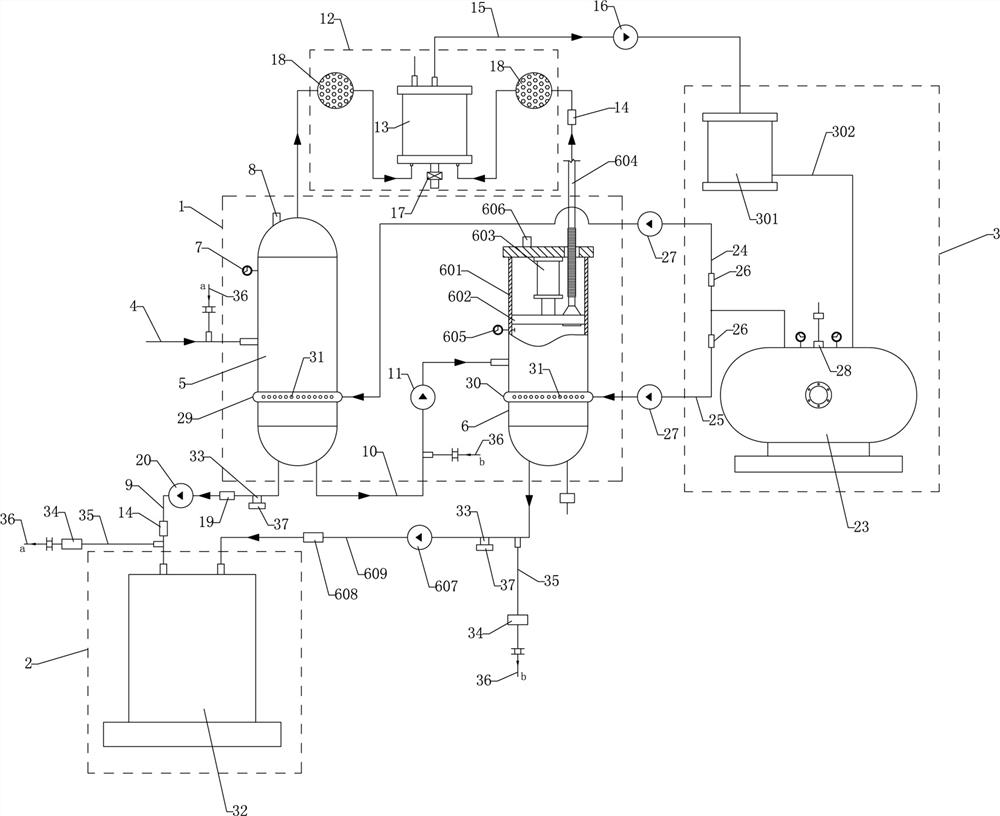

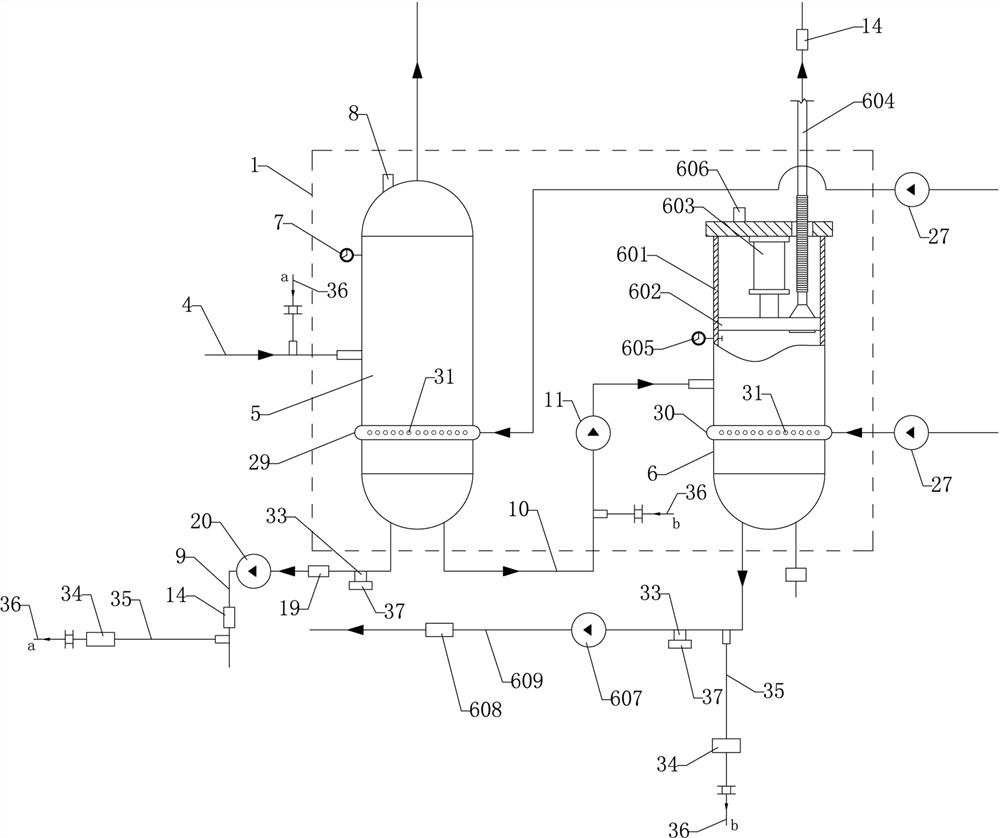

[0031] The monochloroacetone production system comprises a rectification assembly 1, the rectification assembly 1 is connected with the upstream monochloroacetone process equipment, a liquid phase collection assembly 2 is installed at the lower end of the rectification assembly 1, and the rectification assembly 1 is installed with a gas phase collection assembly 3, and a feed pipe 4 is connected outside the middle of the rectification assembly 1, and the rectification assembly 1 is used to carry out distillation treatment and realize gas-liquid separation of the materials conveyed by the feed pipe 4 , the rectification component 1 realizes gas-liquid separation by means of multi-stage distillation extraction.

[0032] This system mainly receives the reaction product from the upstream, and the reaction product enters the interior of the rectification assembly 1 through the feeding pipe 4, so as to realize the heating and distillation of the reaction liquid inside the rectificati...

Embodiment 2

[0060] The monochloroacetone production system comprises a rectification assembly 1, the rectification assembly 1 is connected with the upstream monochloroacetone process equipment, a liquid phase collection assembly 2 is installed at the lower end of the rectification assembly 1, and the rectification assembly 1 is installed with a gas phase collection assembly 3, and a feed pipe 4 is connected outside the middle of the rectification assembly 1, and the rectification assembly 1 is used to carry out distillation treatment and realize gas-liquid separation of the materials conveyed by the feed pipe 4 , the rectification component 1 realizes gas-liquid separation by means of multi-stage distillation extraction.

[0061] This system mainly receives the reaction product from the upstream, and the reaction product enters the interior of the rectification assembly 1 through the feeding pipe 4, so as to realize the heating and distillation of the reaction liquid inside the rectificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com