Biomagnetic nano composite material as well as preparation method and application thereof

A technology of magnetic nano and composite materials, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of long preparation time, secondary pollution of water environment, etc., achieve low price, complete structure, and avoid secondary pollution. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a preparation method of a biomagnetic nanocomposite material, comprising the steps of:

[0050] S1, preparation of nano zero-valent iron-ferric oxide double nanomaterials;

[0051] The step S1 specifically includes:

[0052] S11, dispersing iron ferric oxide particles in an aqueous solution to obtain an aqueous solution of ferric oxide, and then adding a ferrous salt solution to the aqueous solution of ferric oxide to obtain a reduction mixture;

[0053] S12, adding a borohydride solution dropwise to the reduction mixture to perform a reduction reaction to obtain the nano-zero-valent iron-ferric oxide double nanomaterial;

[0054] Wherein, the entire process of the step S11 and the step S12 is carried out under nitrogen protection.

[0055] S2, using polyethyleneimine (PEI) to entrap Fe 3 o 4 -nZVI double nanoparticles to obtain the biomagnetic nanocomposite material.

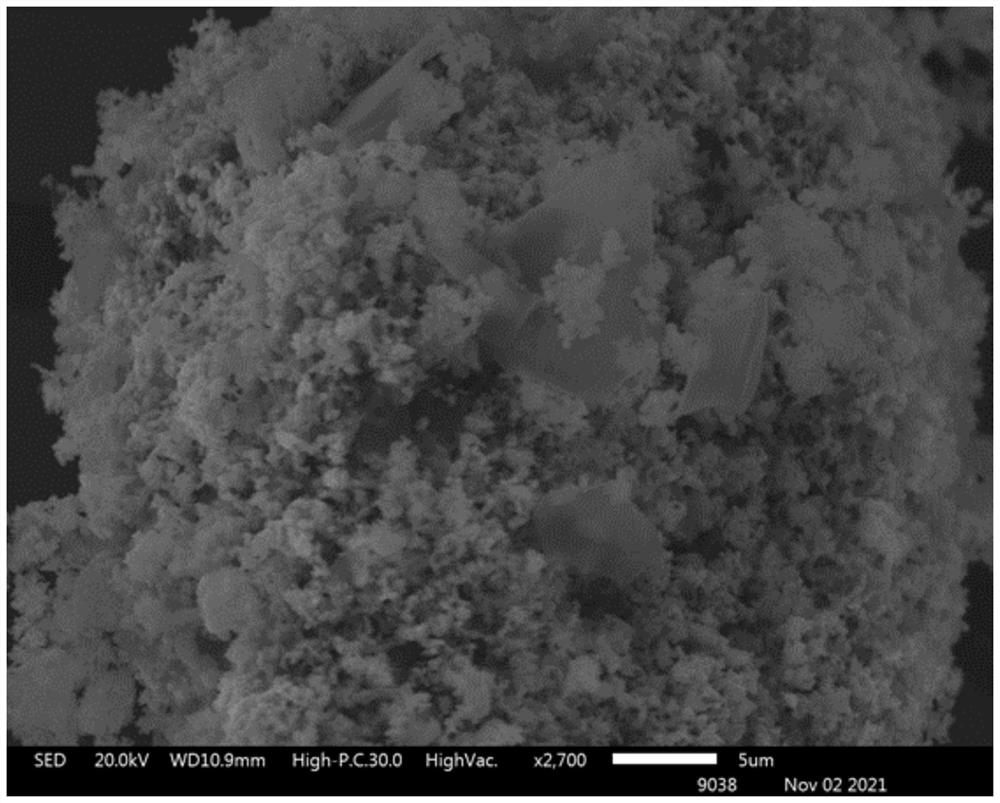

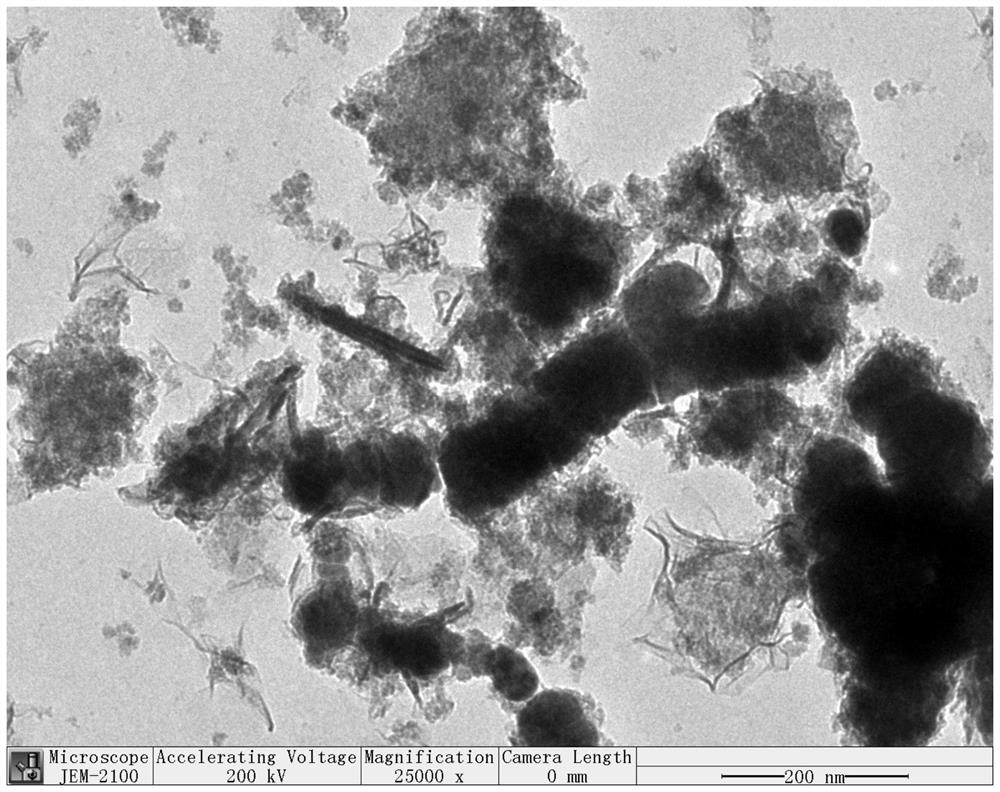

[0056] In the above embodiment, the nano-zero-valent iron is evenly loade...

Embodiment 1

[0072] This example explores Fe 0 and Fe 3 o 4 The optimal mass ratio of , its specific implementation steps are as follows:

[0073] (1) Preparation of different proportions of nanometer zero-valent iron-ferric oxide double nanomaterials: Weigh 0.04g, 0.06g, 0.2g, 0.6g Fe 3 o 4 Dissolve in 100mL deionized water, stir for 1h, transfer the above solutions to 500mL three-necked flasks and feed nitrogen, then add 1g FeSO 4 ·7H 2 O, stirred for 0.5h to ensure FeSO 4 ·7H 2 O completely dissolved, Fe 0 :Fe 3 o 4The mass ratios are 1:0.3, 1:1, 1:3 and 1:5 respectively, stir to dissolve it fully; add 100mL 0.25mol / L NaBH dropwise to the resulting mixture 4 solution for reduction reaction; after 1 hour of reaction, stop nitrogen flow, filter the resulting product, wash with deoxygenated water for 3 to 5 times, and finally freeze-dry for 24 hours to obtain different mass ratios of Fe 3 o 4 -nZVI double nanoparticles (Fe 3 o 4 -nZVI).

[0074] (2) Weigh 0.01 g of nano-size...

Embodiment 2

[0079] This embodiment adopts the best Fe in embodiment 1 0 : Fe 3 o 4 The mass ratio of polyethyleneimine (PEI) embeds nano zero-valent iron-ferric oxide double nanomaterials to obtain biomagnetic nanocomposites. The specific preparation steps are as follows:

[0080] (1) Preparation of nano-zero-valent iron-ferric oxide double nanomaterials: first weigh 0.12g Fe 3 o 4 Dissolve in 200mL deionized water, stir for 1h, transfer the above solution to a 500mL three-necked flask and pass nitrogen gas, then add 2gFeSO 4 ·7H 2 O, stirred for 0.5h to ensure FeSO 4 ·7H 2 O completely dissolved, Fe 0 :Fe 3 o 4 The mass ratio is 1:0.3, stir to make it fully dissolved; dropwise add 200mL 0.25mol / L NaBH to the resulting mixture 4 solution for reduction reaction; after reacting for 1 hour, stop nitrogen flow, filter the resulting product, wash with deoxygenated water for 3 to 5 times, and finally freeze-dry for 24 hours to obtain Fe 3 o 4 -nZVI double nanoparticles (Fe 3 o 4 -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com