Preparation method of waterborne epoxy-modified graphene oxide nano composite coating

A nano-composite coating, water-based epoxy technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems affecting the anti-corrosion performance of graphene oxide/polymer nano-coating and weak polymer interface interaction , prone to agglomeration and other problems, to achieve the effect of promoting compatibility and dispersion, increasing interaction, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of graphene oxide aqueous dispersion, specifically:

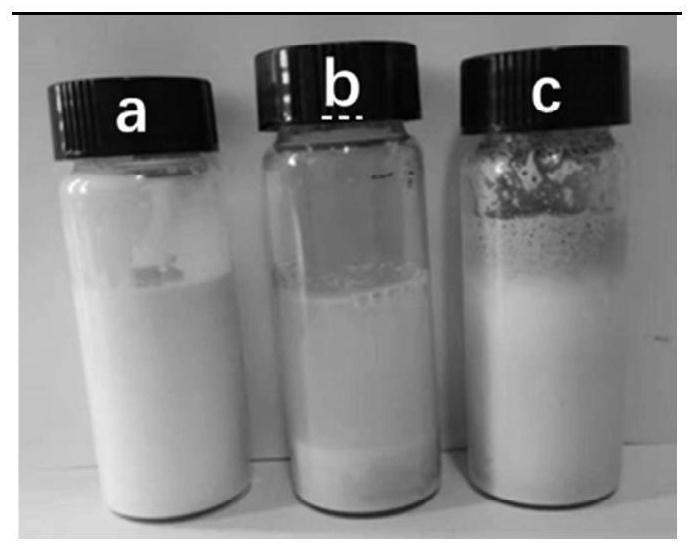

[0039] Weigh 1.82 g of graphene oxide filter cake (solid content 44%, sheet diameter 10-30 μm, thickness 0.5-1 nm), add it to 80 ml deionized water, and prepare a uniform graphene oxide water dispersion in an ice-water bath by ultrasonication for 1 h. The concentration is 10mg / ml.

Embodiment 2

[0041] The preparation method (chemical modification) of modified graphene oxide dispersion liquid is specifically:

[0042]The PBS damping fluid of 200ml PH5.5 is joined in the 500ml there-necked flask, and in ice-water bath, add 3.1g 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC) and 0.46g N-hydroxysuccinimide compound (NHS), stirred for 15min until fully dissolved. Then slowly add 80ml of graphene oxide aqueous dispersion (10mg / ml) (graphene oxide filter cake has a solid content of 44%, sheet diameter of 10-30μm, thickness of 0.5-1nm), and continue stirring in an ice bath for 12h. Then add PBS buffer (pH14) to adjust the pH to 7.4, then add 5g of polyetheramine PEA (D400) and stir at room temperature for 4h, centrifuge and wash until the supernatant is neutral, and redisperse in deionized water to prepare a 10mg / ml modified Graphene oxide dispersion.

Embodiment 3

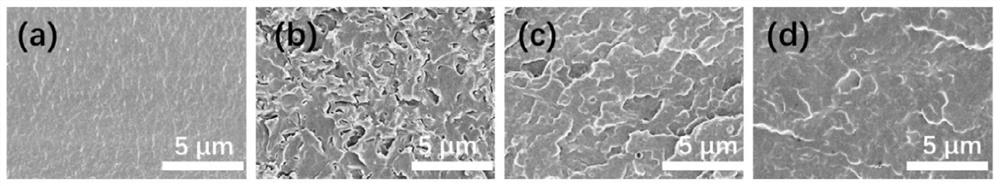

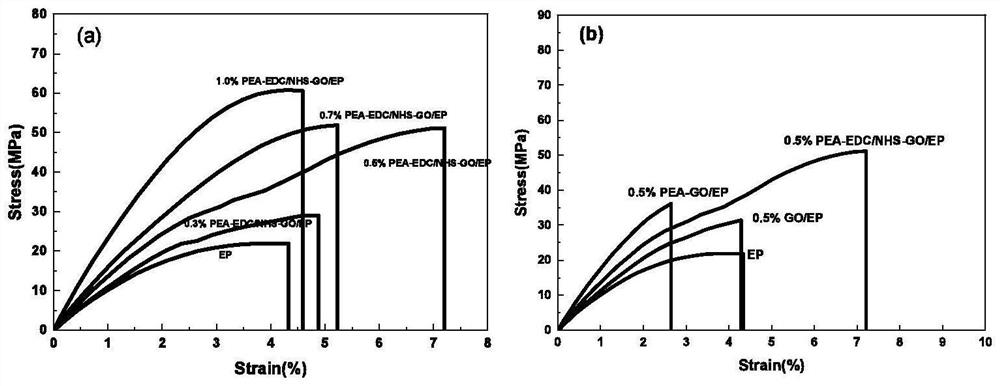

[0044] The preparation method of aqueous epoxy / modified graphene oxide composite emulsion and composite film is specifically:

[0045] Get the modified graphene oxide aqueous dispersion 1.6ml, 2.7ml, 3.7ml, 5.3ml prepared in Example 2 and join respectively in a 100ml three-necked flask, and add 10g water-based epoxy emulsion (PZ3961-1 bisphenol A type, Concentration 53wt%) and an appropriate amount of deionized water to adjust the system concentration to 20wt%, and continue at room temperature for 2 hours until uniform, to obtain a water-based epoxy / modified graphene oxide composite emulsion. Then add 2.18 g of curing agent (Aradur 3986 aliphatic amines, concentration 80wt%) according to the ratio (waterborne epoxy resin: curing agent = 1: 0.33) and stir for 1 hour. After mixing evenly, pour the composite emulsion into a glass mold and dry at room temperature 48h to obtain a water-based epoxy / modified graphene oxide composite film. According to the amount of modified graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com