Application of fatty acid elongase gene in yeast synthesis of nervonic acid

A technology of neuramic acid and Yarrowia lipolytica, which is applied in the fields of application, genetic engineering, and plant genetic improvement, and can solve the problems of insufficient pathogenic production potential of neuric acid-producing microorganisms and inability to industrialize production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

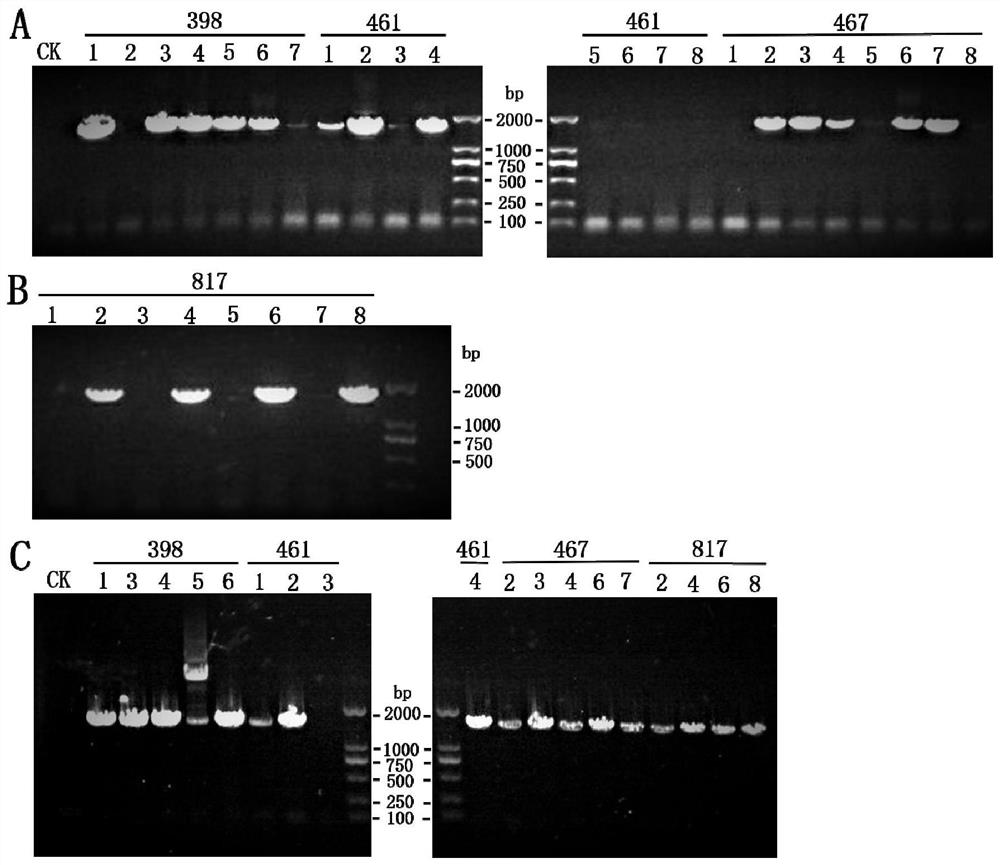

[0111] Example 1: Yeast expresses MaoleKCS to synthesize nervonic acid

[0112] 1. Materials and Methods

[0113] 1.1 Strains and culture conditions

[0114] The starting strain of Yarrowia lipolytica used in the examples is Y. lipolytica Po1g (MATa, leu2-270, ura3-302::URA3, xpr2-3), purchased from Yeastern Biotech Co., Ltd. The bacterial strain Po1g-G3-ΔURA was obtained by the following method, specifically: the bacterial strain Po1g-G3 was obtained by overexpressing the endogenous genes DGAT1, ACC1 and SCD genes of Yarrowia lipolytica (Qiao and Stephanopoulos.Metabolic Engineering, 2015, 29 :56-65), and then reverse screening by 5-FOA method to obtain uracil auxotrophic strain Po1g-G3-ΔURA.

[0115] The culture temperature used by Yarrowia lipolytica is 28°C, and the shaker speed is 220rpm during liquid culture, and the culture medium used is as follows:

[0116] YPD liquid medium: glucose 20g / L, peptone 20g / L, yeast extract 10g / L, if solid medium is required, add 1.5% a...

Embodiment 2

[0190] Embodiment 2: fermenter fermentation of recombinant bacterial strain

[0191] 1. Materials and methods

[0192] 1.1 Fermentation medium

[0193] Seed culture medium (YNB medium): YNB 3g / L, glucose 60g / L, ammonium sulfate 35g / L, YNB and ammonium sulfate were sterilized and added by filtration.

[0194] Fermentation medium (FM medium): glucose 50g / L, ammonium sulfate 35g / L, yeast powder 38g / L, potassium dihydrogen phosphate 8g / L, disodium hydrogen phosphate dodecahydrate 6g / L, magnesium sulfate heptahydrate 5g / L, defoamer 1mL / L.

[0195] Feed control: control according to the residual sugar concentration in the fermenter, and use 600g / L glucose feed after sterilization.

[0196] 1.2 Fermentation process of 50L fermenter

[0197] The preserved strains were taken out from -80°C and thawed on ice. Draw 100μl and inoculate into 250mL YNB medium, culture on a shaker at 220rpm and 28°C for 24 hours, then transfer to a 5L seed fermentation tank with an OD of about 0.01 after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com