Nervonic acid composition and application thereof in neuroprotection

A technology of nervonic acid and composition, applied in the field of medicine, can solve the problems such as functional disorders and there is no very effective method, and achieve the effects of improving cerebral blood and cerebral metabolic functions, reducing pain and shortening the course of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of the nervous acid composition provided by the invention is not particularly limited, as long as the components are mixed.

[0067] The invention provides the application of the nervonic acid composition in the preparation of neuroprotective medicines.

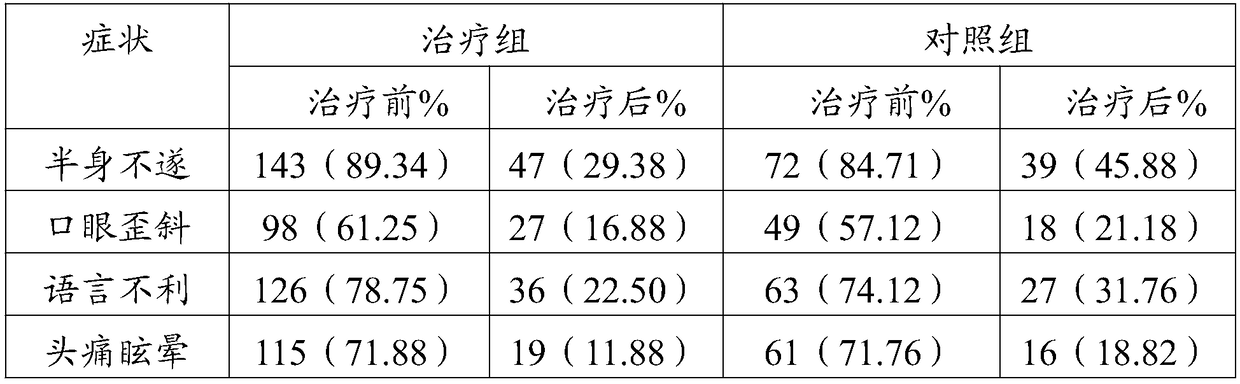

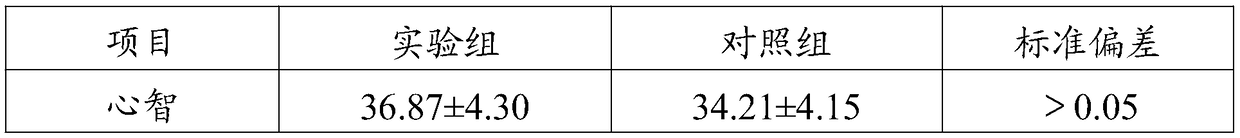

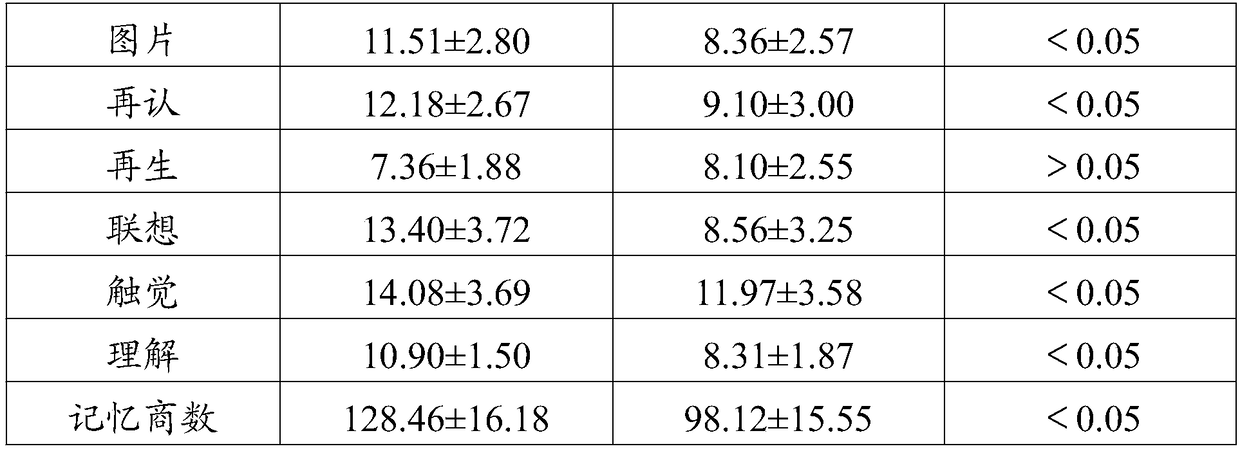

[0068] In the present invention, the neuroprotection preferably includes neuroprotection in establishing collateral circulation after cerebral apoplexy, reducing or avoiding the dysfunction and disability of the patient's limbs, language and spirit, hemiplegia, aphasia, and peripheral neuropathy caused by cerebral apoplexy Aspects, promoting intellectual development, delaying brain aging, repairing nerve cell damage and / or preventing and improving encephalopathy.

[0069] In the present invention, the medicine also includes auxiliary materials. The auxiliary materials include non-dairy creamer, sucrose, maltitol, starch, dextrin, maltodextrin, gelatin, glycerin, water, starch, silicon dioxide, m...

Embodiment 1

[0076] Neural acid-containing vegetable oil extraction

[0077] Remove impurities and shells from the seeds of Maple indica, winnow the seed kernels of Maple indica, grind the seed kernels of Maple ingot into a fine powder with a particle size of less than 300 microns; use petroleum ether as an extraction solvent for ultrasonic extraction; petroleum ether and seeds The mass ratio of kernel powder to liquid is 1:10, the ultrasonic power is 50W, the ultrasonic time is 70min, and the temperature is 38-42°C. Crude oil is refined to obtain oil with a peroxide value lower than 0.20g / 100g.

Embodiment 2

[0079] Production of oil powder

[0080] 1 part of vegetable oil or celery seed oil containing nervous acid, 1.5 parts of sodium starch octenyl succinate, 1.5 times of sodium starch in purified water. Soak octenyl starch sodium succinate in purified water for 6 hours, stir to dissolve, add nervous acid vegetable oil or celery seed oil, cut the material with a shearing machine (12000 rpm) for 10 minutes, and import the material into a homogenizer to control The temperature is 40-60°C, the pressure is 10-18MPa, the material is homogenized twice, and the homogenized material is spray-dried, the spray pressure is 15-20MPa, the inlet temperature is 140-160°C, the exhaust air temperature is 70-80°C, after spraying Dry to obtain powdered oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com