Preparation method and application of titanium silicalite molecular sieve catalyst

A titanium-silicon molecular sieve and catalyst technology, which is applied in the field of titanium-silicon molecular sieve catalyst preparation, can solve the problems of limited application range, limited skeleton Ti content, and difficulty in application, and achieve the effect of increasing conversion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

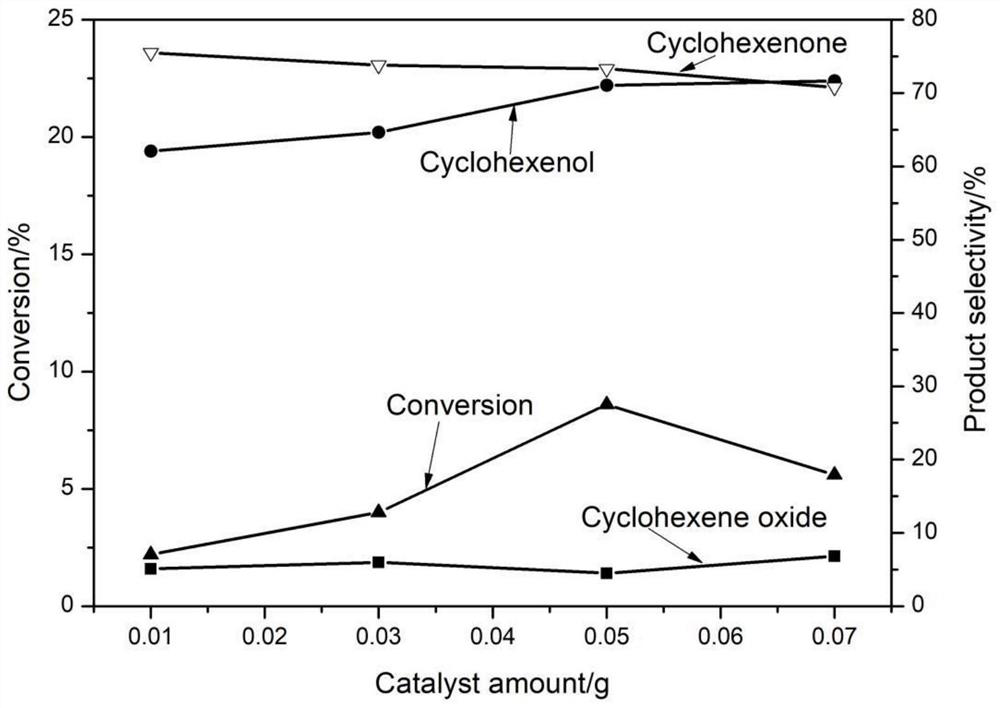

Examples

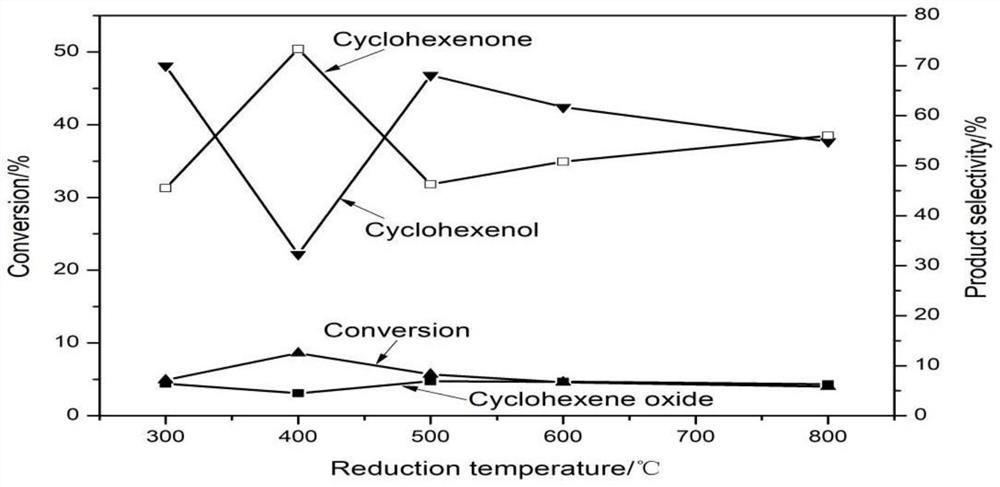

Embodiment 1

[0030] 1) Preparation of TS-1: n-butyl titanate (TBOT) was used as a titanium source, tetraethyl silicate (TEOS) was used as a silicon source, and tetrapropylammonium hydroxide (TPAOPH) was used as a template agent. According to the molar ratio 0.037(TBOT):1(TEOS):0.25(TPAOPH):35(H 2 O) Preparation. The specific steps are as follows: first, 0.2 mol of TPAOH and 12.5 mol of distilled water were placed in a beaker, then 0.8 mol of TEOS was slowly added to it under magnetic stirring, and after stirring for one hour, 0.03 mol of TBOT and 0.03 mol of TBOT were added while stirring. 0.9 mol of absolute ethanol. After stirring for 24 hours, it was put into a drying oven at 80°C to remove absolute ethanol, then cooled to normal temperature, and the mixed solution was placed in a tetrafluoroethylene-lined crystallization kettle, and crystallized in a thermostat at 170°C. three days. After cooling, filtering, washing, drying at 120°C, it was fired in a muffle furnace at 500°C for 10 ...

Embodiment 2

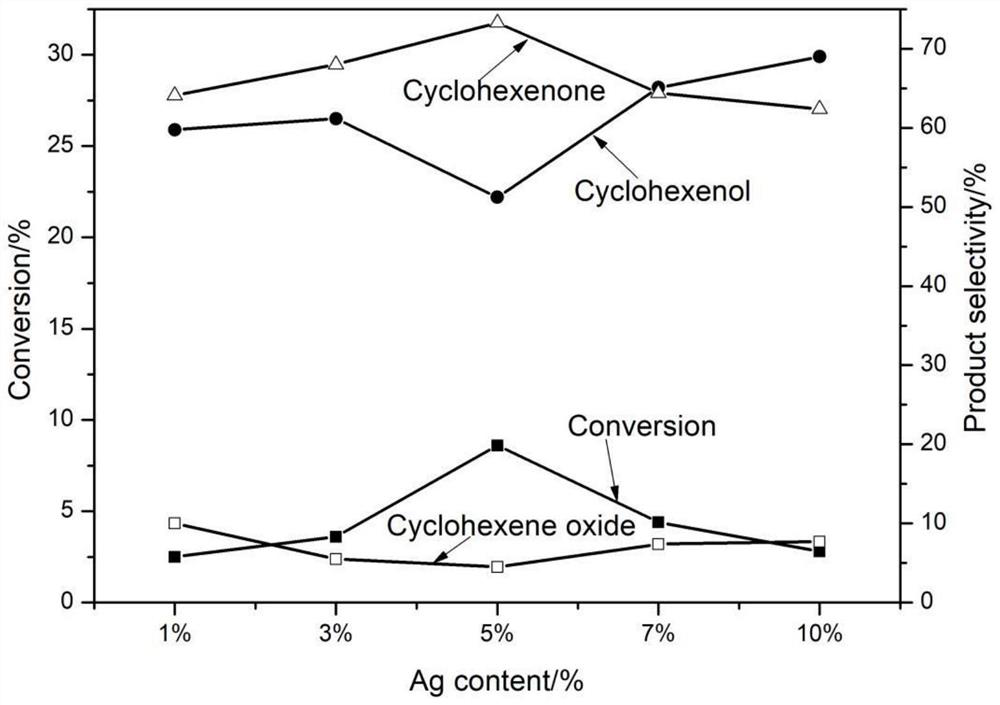

[0035] This example refers to the preparation method of Example 1, and the main difference is that the Ag loading is adjusted to 1%.

Embodiment 3

[0037] This example refers to the preparation method of Example 1, and the main difference is that the Ag loading is adjusted to 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com