High-thixotropic flame-retardant water-based transparent nail-free glue and preparation method thereof

A high thixotropic, nail-free adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of affecting the appearance, low environmental protection level, generation of smoke and toxic gases, etc., to avoid Effects of adverse effects, good environmental friendliness, excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

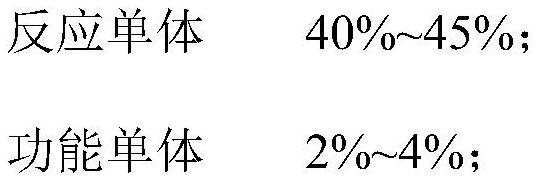

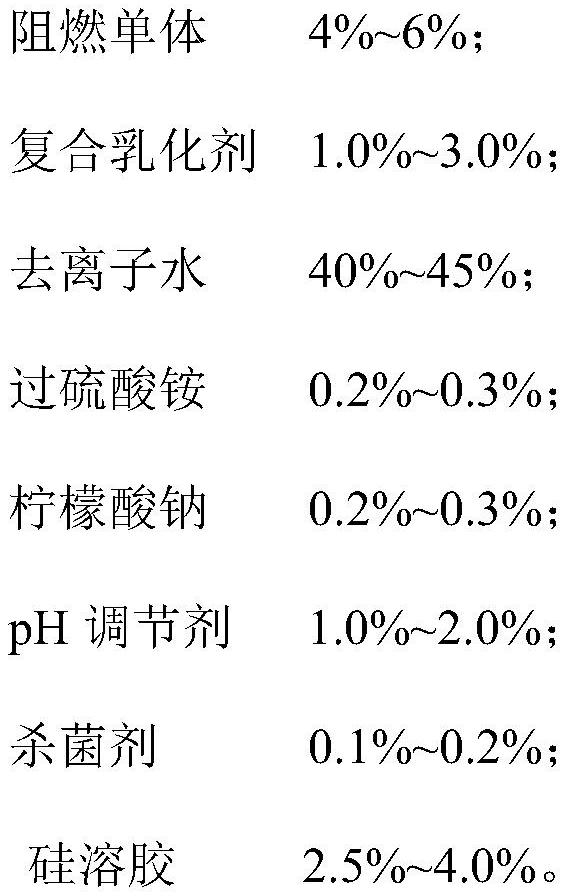

[0042] The composition ratio of a highly thixotropic flame retardant water-based transparent nail-free adhesive:

[0043]

[0044] The preparation method is as follows:

[0045] ①Preparation of pre-emulsion

[0046] Add 105g deionized water, 3.0g SR-10, 3.0g ER-10 emulsifier in sequence to the emulsifier and stir for 1 hour until the dispersion is uniform to obtain an emulsifier aqueous solution; add mixed monomers (110g styrene, 189g butyl acrylate) to the emulsifier aqueous solution dropwise ester, 16 g of acrylic acid, 14 g of 4-hydroxybutyl acrylate, 28 g of hydroxyethyl methacrylate phosphate), and stirred for 1 hour until the dispersion was uniform, and 468 g of a pre-emulsion was obtained.

[0047] ② Preparation of seed emulsion

[0048] a. Dissolve 1.4g of ammonium persulfate in 10g of deionized water to prepare 11.4g of initiator aqueous solution;

[0049] b, successively add 200g deionized water, 1.4g sodium citrate, 20g pre-emulsion, 0.5g SR-10, 0.5g ER-10 emu...

Embodiment 2

[0056] The composition ratio of a highly thixotropic flame retardant water-based transparent nail-free adhesive:

[0057]

[0058]

[0059] The preparation method is as follows:

[0060] ①Preparation of pre-emulsion

[0061] Add 105g deionized water, 10g SR-10, 3g ER-10 emulsifier in turn to the emulsifier and stir for 1 h until the dispersion is uniform; add mixed monomers (98g styrene, 168g butyl acrylate, 14g acrylic acid, 28g 4 -Hydroxybutyl acrylate, 42 g of hydroxyethyl methacrylate phosphate), stirred for 1 h until the dispersion was uniform, and 468 g of a pre-emulsion was obtained.

[0062] ② Preparation of seed emulsion

[0063] a. Dissolve 2.0 g of ammonium persulfate in 10 g of deionized water to prepare 12 g of an aqueous initiator solution;

[0064] b. Add 181.3g deionized water, 2.0g sodium citrate, 20g pre-emulsion, 0.5g SR-10, 0.5g ER-10 emulsifier successively to the reaction kettle and heat up to 78°C with stirring; add 3.3g initiator to the reactio...

Embodiment 3

[0071] The composition ratio of a highly thixotropic flame retardant water-based transparent nail-free adhesive:

[0072]

[0073] The preparation method is as follows:

[0074] ①Preparation of pre-emulsion

[0075] Add 105g deionized water, 14.5g SR-10, 5.5g ER-10 emulsifier in sequence to the emulsifier and stir for 1 h until dispersed uniformly; add mixed monomers (98g styrene, 168g butyl acrylate, 14g acrylic acid, 16 g of 4-hydroxybutyl acrylate, 28.6 g of hydroxyethyl methacrylate phosphate), stirred for 1 hour until dispersed uniformly, and obtained 449.6 g of pre-emulsion.

[0076] ② Preparation of seed emulsion

[0077] a. Dissolve 2.0 g of ammonium persulfate in 10 g of deionized water to prepare 12 g of an aqueous initiator solution;

[0078] b, successively add 200g deionized water, 2.0g sodium citrate, 20g pre-emulsion, 0.5gSR-10, 0.5gER-10 emulsifier to the reaction kettle and heat up to 78°C with stirring; add 3.3g aqueous initiator solution to the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com