Synthetic process of mixed double-chain quaternary ammonium salt complex iodine for aquaculture

A double-chain quaternary ammonium salt and aquaculture technology, which is applied in the synthesis process of mixed double-chain quaternary ammonium salt complexed iodine, can solve the problems of iodide ion loss, affecting the use effect, and occurrence of algae, and achieve strong slime peeling Function, high bactericidal efficiency and wide bactericidal spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

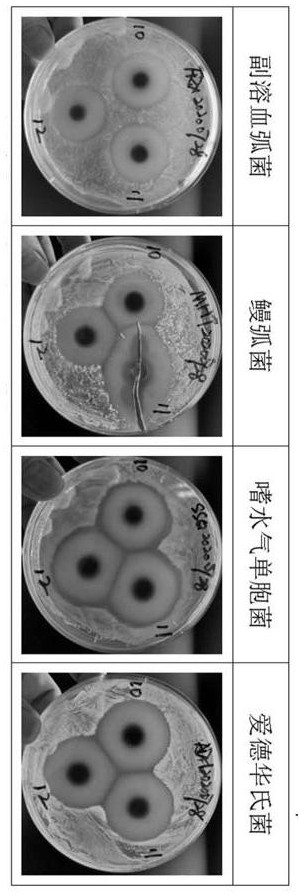

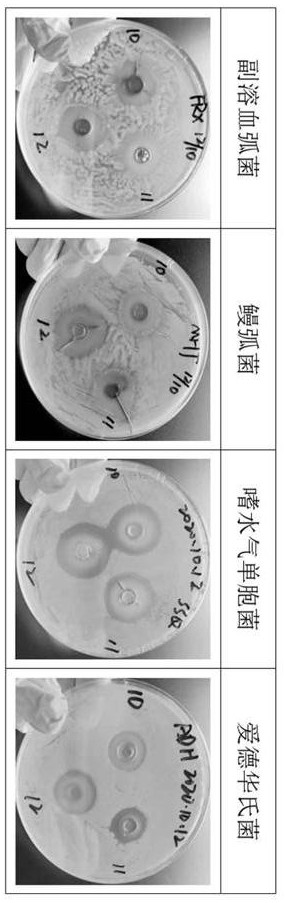

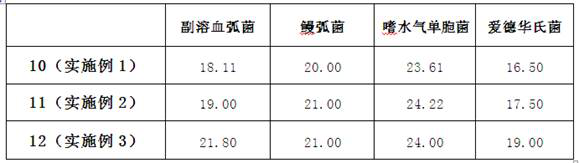

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of synthesis technique for the mixed double-chain quaternary ammonium salt complex iodine of aquaculture mentioned in the present invention, comprises the following process:

[0022] 1) Add 300kg of octyldecylmethyl tertiary amine, 200kg of dodecyltetradecylmethyl tertiary amine and 100kg of hexadecyloctadecylmethyl tertiary amine into the reactor, and stir evenly;

[0023] 2) Continue to add 222.2kg of benzyl chloride to the reaction kettle. The amount of benzyl chloride added in the actual reaction process should be calculated according to the calculated amine value of the mixed tertiary amine, or you can directly take the sample of the mixed tertiary amine and use the method of titration. Obtain its amine value, and then calculate the add-on of benzyl chloride;

[0024] 3) pump the methanol of 205.5kg into the reactor;

[0025] 4) Start to heat up, when the temperature rises to 60~80℃, the constant temperature reaction is performed for 2~4 hours...

Embodiment 2

[0030] Embodiment 2: a kind of synthesis technique of the mixed double-chain quaternary ammonium salt complex iodine for aquaculture mentioned in the present invention, comprises the following process:

[0031] 1) Add 200kg of octyldecylmethyl tertiary amine, 200kg of dodecyltetradecylmethyl tertiary amine and 200kg of hexadecyloctadecylmethyl tertiary amine into the reaction kettle, stir evenly;

[0032] 2) Continue to add 203kg of benzyl chloride to the reaction kettle. In the actual reaction process, the amount of benzyl chloride added should be calculated according to the calculated amine value of the mixed tertiary amine, or you can directly take the sample of the mixed tertiary amine and obtain it by titration. Its amine value, and then calculate the add-on of benzyl chloride;

[0033] 3) pump the methanol of 200kg into the reactor;

[0034] 4) Start to heat up, when the temperature rises to 60~80℃, the constant temperature reaction is performed for 2~4 hours;

[0035]...

Embodiment 3

[0039] Embodiment 3: a kind of synthesis technique of the mixed double-chain quaternary ammonium salt complex iodine for aquaculture mentioned in the present invention, comprises the following process:

[0040] 1) Add 100kg octyldecyl methyl tertiary amine, 200kg dodecyl tetradecyl methyl tertiary amine and 300kg hexadecyl octadecyl methyl tertiary amine to the reaction kettle, stir well;

[0041] 2) Continue to add 183.3kg of benzyl chloride to the reaction kettle. The amount of benzyl chloride added in the actual reaction process should be calculated according to the calculated amine value of the mixed tertiary amine, or you can directly take the sample of the mixed tertiary amine and use the titration method Obtain its amine value, and then calculate the add-on of benzyl chloride;

[0042] 3) pump the methanol of 196kg into the reactor;

[0043] 4) Start to heat up, when the temperature rises to 60~80℃, the constant temperature reaction is performed for 2~4 hours;

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com