Composite powder particle of high-vanadium and high-boron alloy for surfacing and application method of composite powder particle

An application method and composite powder technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of low melting point, unutilized, continuous service, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

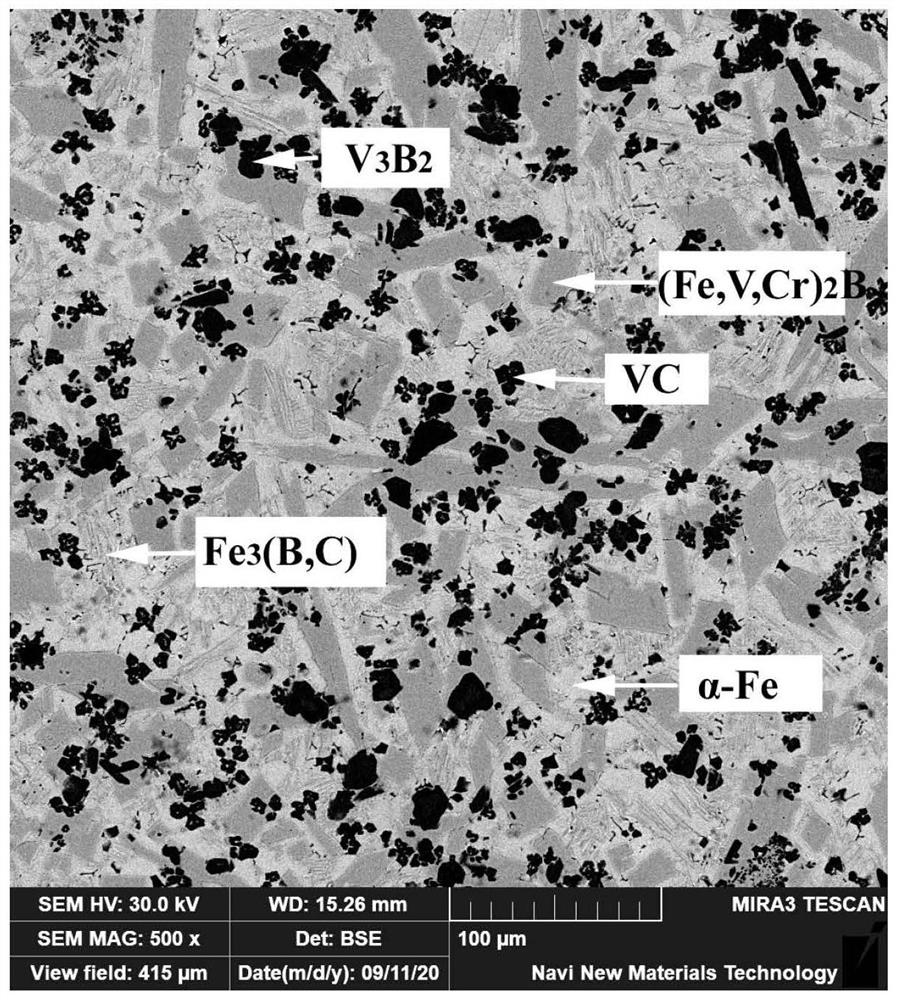

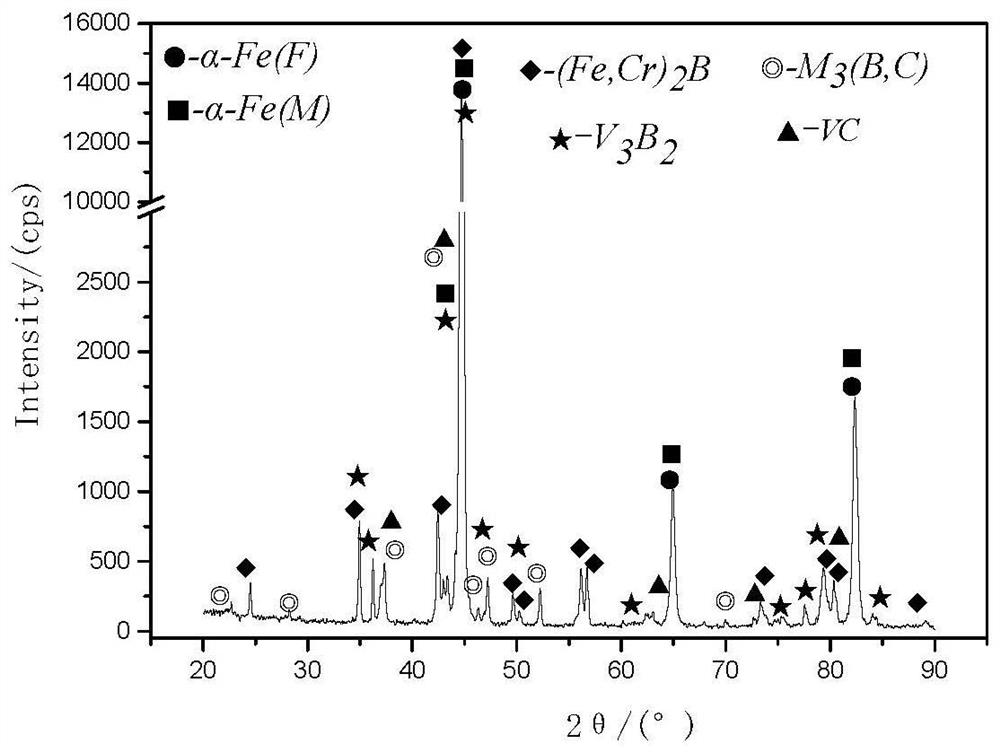

Embodiment 1

[0040] Before weighing, the powder components such as ferrovanadium, boron carbide, metallic chromium, ferrosilicon, medium carbon ferromanganese and reduced iron powder were all passed through a 60-mesh sieve, and the aluminum powder was passed through a 300-mesh sieve. The composition ratio (weight percentage) of the powder components contained in the composite powder particles is: 60% of ferrovanadium, 20% of boron carbide, 8% of metallic chromium, 2% of ferrosilicon, 3% of medium carbon ferromanganese, and 1% of aluminum powder , Reduced iron powder 6%. Weigh the powder components such as ferrovanadium, boron carbide, metal chromium, ferrosilicon, medium carbon ferromanganese, aluminum powder and reduced iron powder according to the proportioning requirements of the powder components contained in the above composite powder; The above-mentioned powder components are put into the same container, and fully stirred to make them evenly mixed to form mixed powder.

[0041] Next...

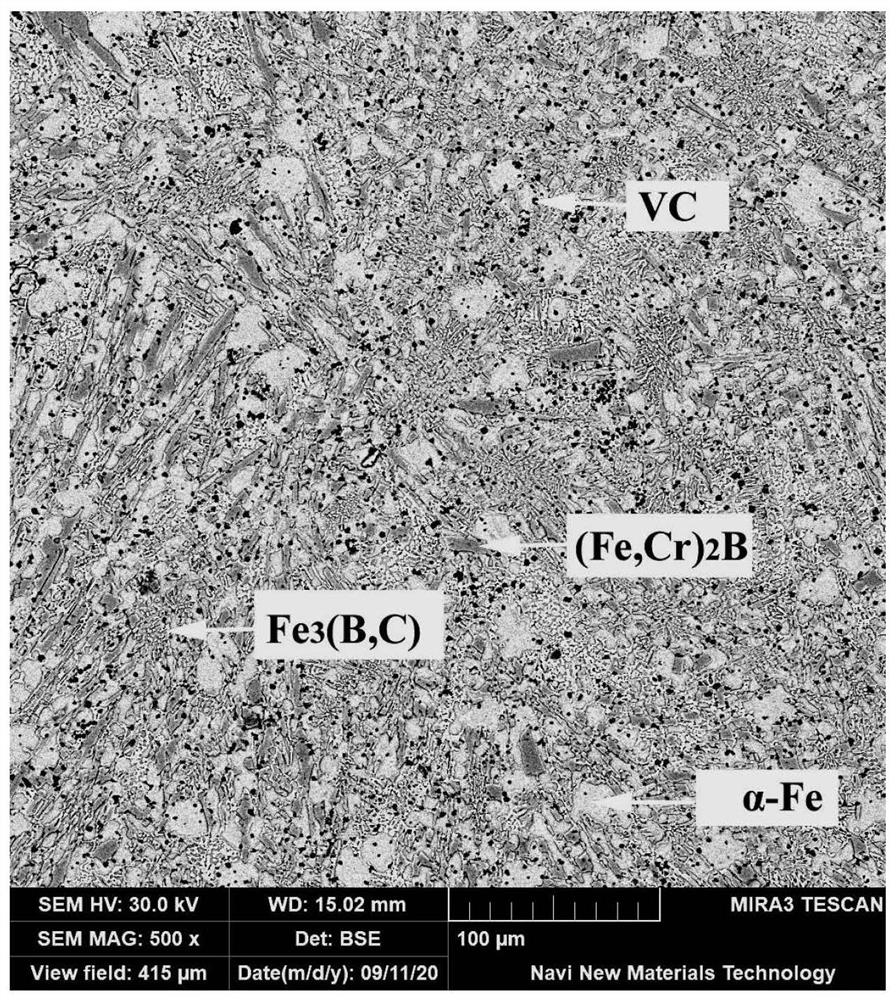

Embodiment 2

[0054] Before weighing, the powder components such as ferrovanadium, boron carbide, metallic chromium, ferrosilicon, medium carbon ferromanganese and reduced iron powder were all passed through a 60-mesh sieve, and the aluminum powder was passed through a 300-mesh sieve. The composition ratio (weight percentage) of the powder components contained in the composite powder particles is: 55% of ferrovanadium, 18% of boron carbide, 10% of metallic chromium, 3% of ferrosilicon, 3% of medium carbon ferromanganese, and 1.5% of aluminum powder , Reduced iron powder 9.5%. Weigh the powder components such as ferrovanadium, boron carbide, metal chromium, ferrosilicon, medium carbon ferromanganese, aluminum powder and reduced iron powder according to the proportioning requirements of the powder components contained in the above composite powder; The above-mentioned powder components are put into the same container, and fully stirred to make them evenly mixed to form mixed powder.

[0055]...

Embodiment 3

[0061] Before weighing, the powder components such as ferrovanadium, boron carbide, metallic chromium, ferrosilicon, medium carbon ferromanganese and reduced iron powder were all passed through a 60-mesh sieve, and the aluminum powder was passed through a 300-mesh sieve. The composition ratio (weight percentage) of the powder components contained in the composite powder particles is: ferrovanadium 58%, boron carbide 19%, metal chromium 12%, ferrosilicon 3%, medium carbon ferromanganese 2%, aluminum powder 1% , Reduced iron powder 5%. Weigh the powder components such as ferrovanadium, boron carbide, metal chromium, ferrosilicon, medium carbon ferromanganese, aluminum powder and reduced iron powder according to the proportioning requirements of the powder components contained in the above composite powder; The above-mentioned powder components are put into the same container, and fully stirred to make them evenly mixed to form mixed powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com