Preparation method of high-purity silicon tungsten powder

A high-purity, silicon-tungsten technology, applied in the field of powder metallurgy, can solve the problems of low product purity, low reduction temperature, and high oxygen content of high-purity silicon powder, and achieve the effect of broad application market, reducing C deposition, and reducing C content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

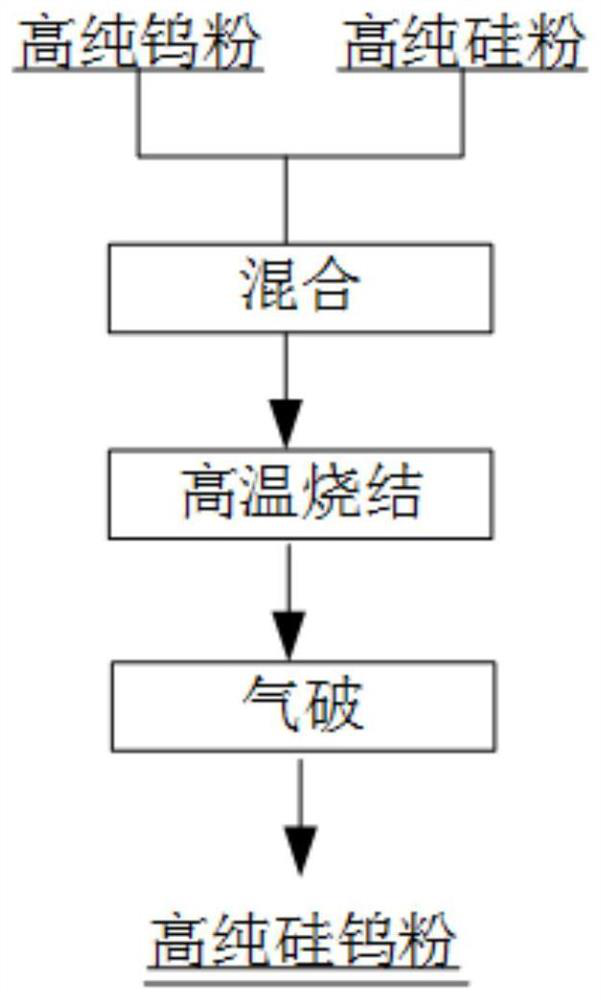

[0025] The present invention provides a preparation method of high-purity silicon-tungsten powder, which is characterized in that, comprising the following steps:

[0026] (1) Mix the high-purity tungsten powder and the high-purity silicon powder uniformly in a three-dimensional mixer, wherein the mixing medium is high-purity silicon balls;

[0027] (2) The mixed powder is placed in a high-temperature sintering furnace for sintering, and a mixed gas of high-purity hydrogen and high-purity methane is first introduced to carry out the first sintering process, wherein the flow volume ratio of the mixed gas is H 2 :CH 4 1000:1~500:1, then turn off the methane, and pass in high-purity hydrogen to continue the second sintering process;

[0028] (3) The sintered silicon-tungsten powder is subjected to gas breaking treatment to prepare high-purity silicon-tungsten powder.

[0029] Further, in the embodiment of the present invention, the high-purity tungsten powder described in step ...

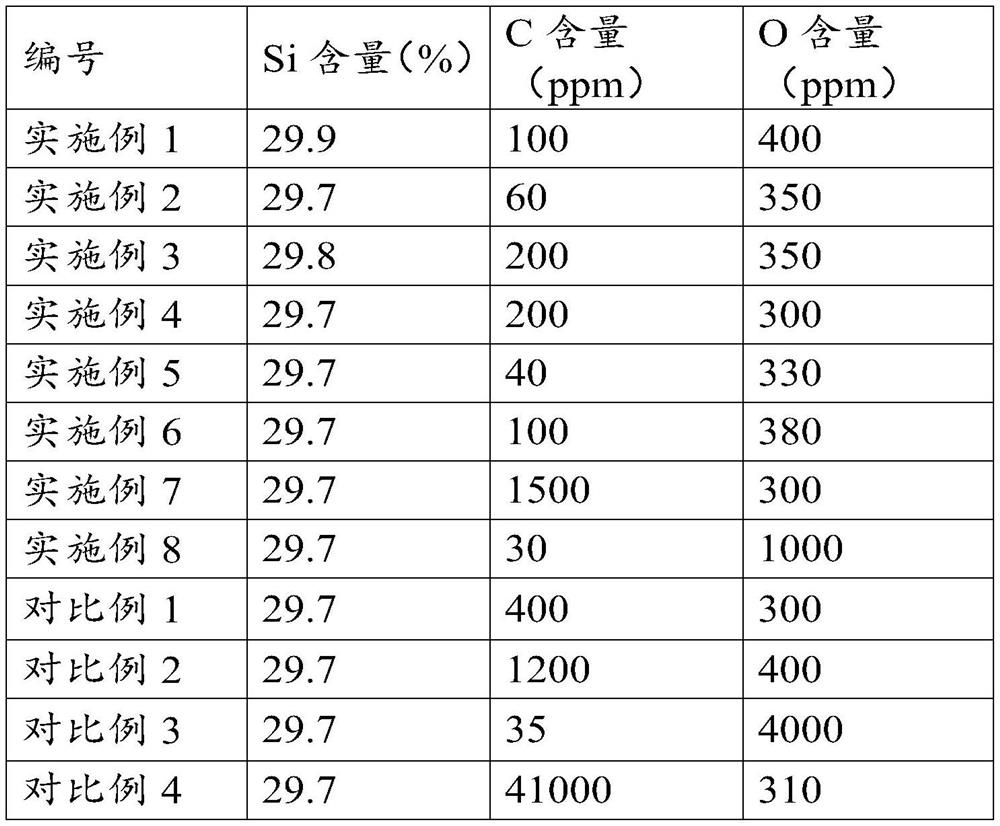

Embodiment 1

[0043] 1. The high-purity tungsten powder and the high-purity silicon powder are mixed evenly with argon gas as a protective gas in the three-dimensional mixer. Among them, the Si content is 29.7%, the mixing time is 3h, the mixing medium is high-purity silicon balls, and the ball-to-material ratio is 1:3.

[0044] 2. Put the mixed powder in a high-temperature sintering furnace for sintering, the sintering temperature is 1200 ℃, and the mixed gas of high-purity hydrogen and high-purity methane is introduced, and the gas flow ratio is H 2 :CH 4 1000:1, sintered for 2h; then turned off the methane, sintered with pure hydrogen for 1h, and passed high-purity argon to cool down after the reaction was completed.

[0045] 3. The sintered silicon-tungsten powder is subjected to gas breaking treatment to prepare high-purity silicon-tungsten powder.

[0046] 4. The Si content in the high-purity silicon-tungsten powder is 29.9%, the C content is 100ppm, and the O content is 400ppm.

Embodiment 2

[0048] 1. The high-purity tungsten powder and the high-purity silicon powder are mixed evenly with argon gas as a protective gas in the three-dimensional mixer. Among them, the Si content is 29.7%, the mixing time is 2h, the mixing medium is high-purity silicon balls, and the ball-to-material ratio is 1:2.

[0049] 2. Put the mixed powder in a high-temperature sintering furnace for sintering, the sintering temperature is 1300 ℃, and the mixed gas of high-purity hydrogen and high-purity methane is introduced, and the gas flow ratio is H 2 :CH 4 1000:1, sintered for 2 hours; then turned off the methane, sintered with pure hydrogen for 3 hours, and cooled with high-purity argon after the reaction was completed.

[0050] 3. The sintered silicon-tungsten powder is subjected to gas breaking treatment to prepare high-purity silicon-tungsten powder.

[0051] 4. The Si content in the high-purity silicon-tungsten powder is 29.7%, the C content is 60ppm, and the O content is 350ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com