Anterior tooth facing ceramic material and preparation method thereof

A technology for veneer porcelain and anterior teeth, applied in the field of tooth veneer materials, can solve the problems of low visible light transmittance, difficult to use anterior teeth veneer porcelain materials, etc., and achieves high visible light transmittance, moderate toughness, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

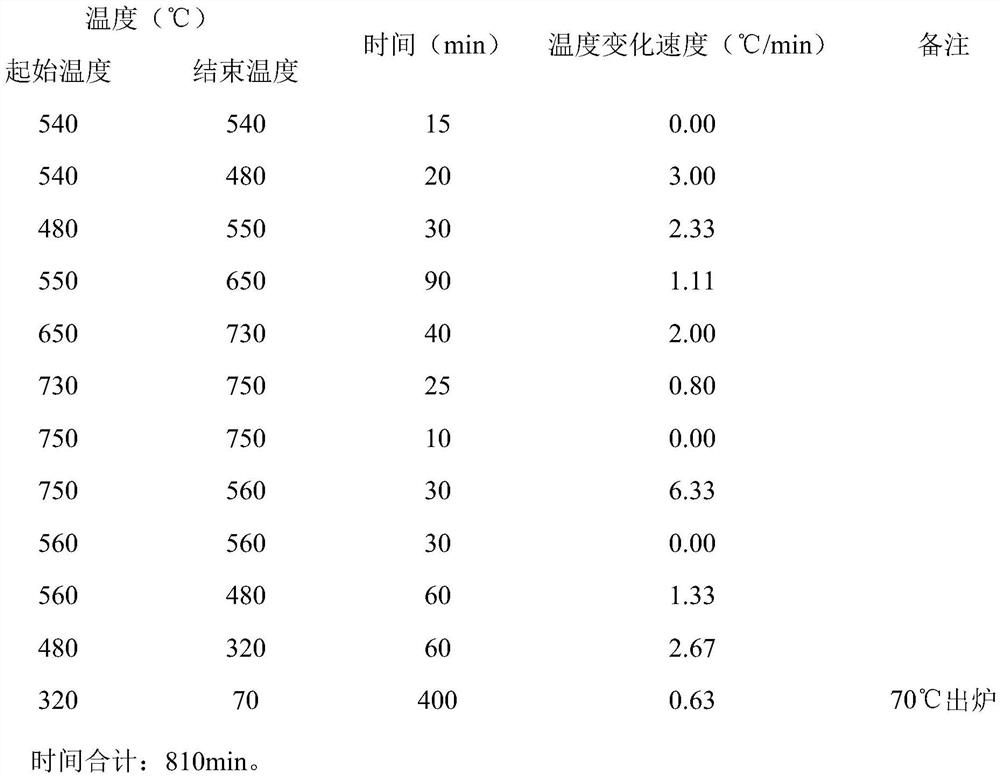

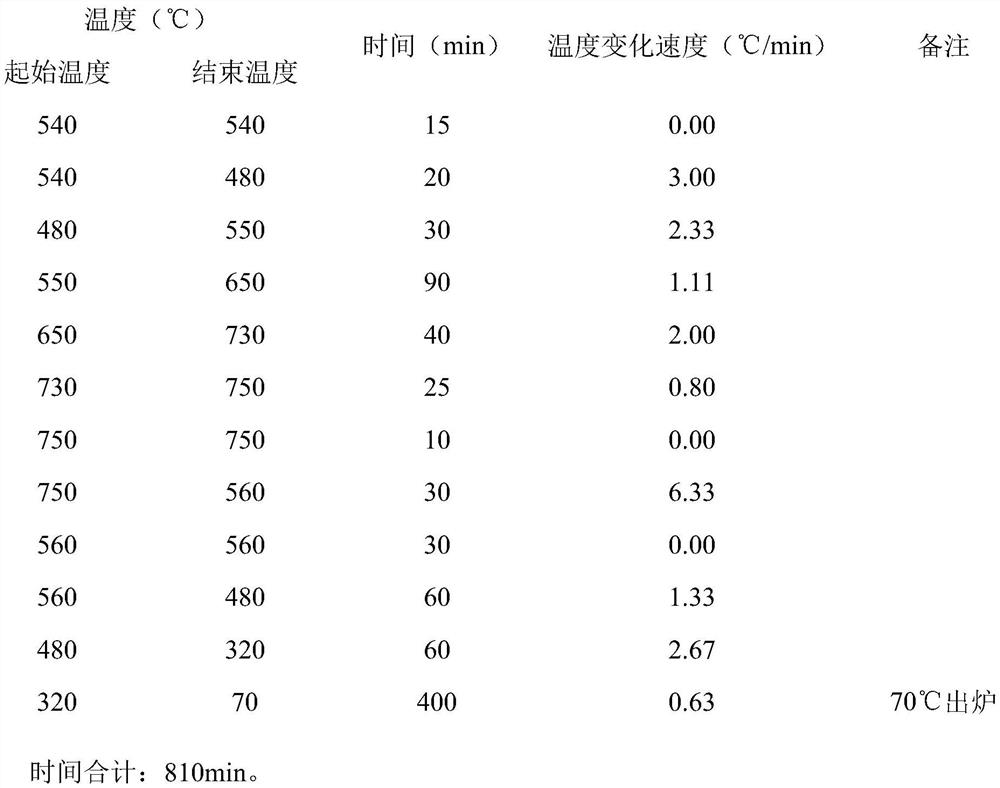

[0033] The preparation method of a kind of anterior tooth veneer porcelain material of Examples 1-6 and Comparative Examples 1-4, the steps are:

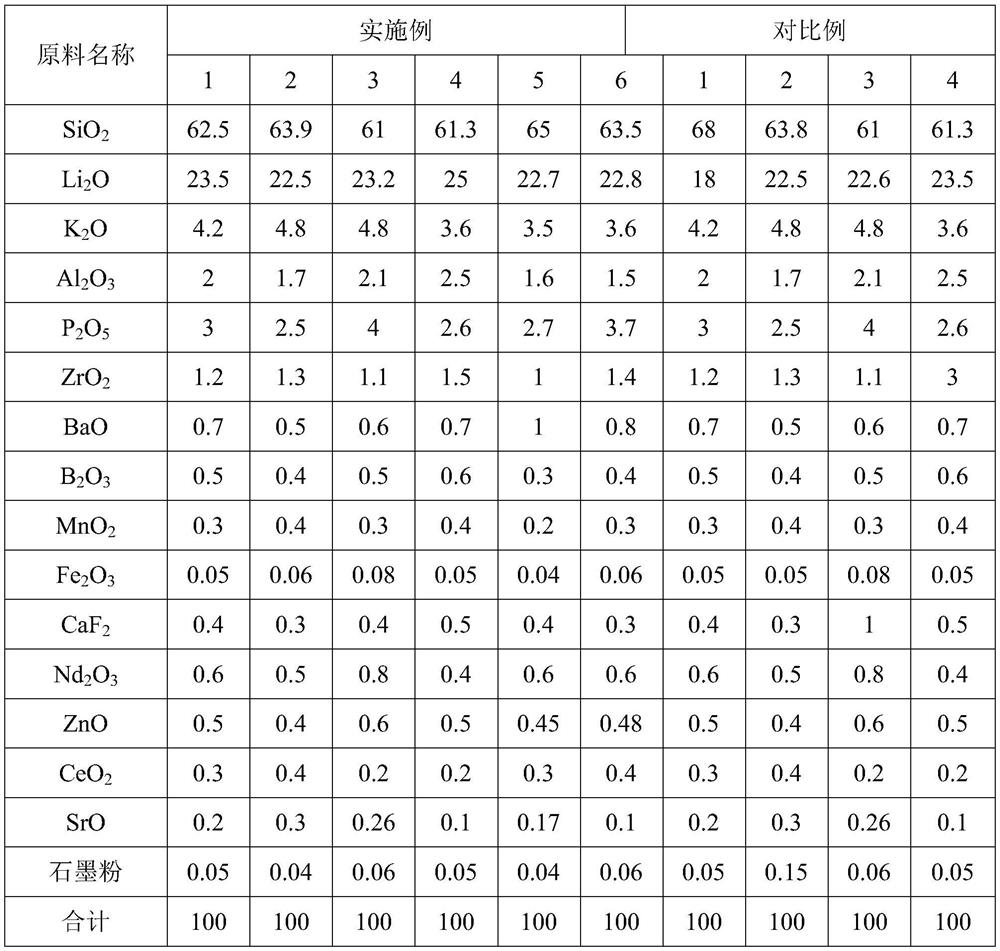

[0034] (1) Weigh the nano-γ-Al according to the weight percentage 2 O 3 , nano-zirconia, barium carbonate, boric acid, manganese dioxide, ferric oxide, calcium fluoride, ultra-fine neodymium oxide, zinc oxide, ceria, ultra-fine strontium oxide, high-purity graphite powder Mixed into a uniform batch A in the all-round mixer, and the coefficient of variation of the mixing uniformity of the batch A is less than 2.5%;

[0035] (2) Weigh high-purity quartz sand, lithium carbonate, potassium carbonate and phosphorus pentoxide according to weight percentage and add them to the all-round mixer and mix them into uniform batching material B, and the mixing uniformity coefficient of variation of batching material B is less than 5 %;

[0036] (3) adding batching material A to batching material B, and mixing into uniform batching material C i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Three-point bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com