Spinning labeled starch and preparation method thereof

A technology of spin labeling and starch, applied in the field of starch modification, can solve problems such as destroying the original conformation of molecules, and achieve the effects of easy operation, simple process route and stable chemical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take 2.0 g of corn starch and add 25 mL of anhydrous DMSO to dissolve at 25 ° C for 10 h to prepare a starch solution for later use. Dissolve 1 g of hexamethyl diisocyanate and 50 mg of 4-amino Tempo in 10 mL of anhydrous DMSO, and after continuous stirring for 2 h, mix it with the above starch solution and continue stirring for 24 h to obtain a mixed sample.

[0040] Use a dialysis bag with a molecular weight of 8000-16000 to hold the mixed sample and seal it, then submerge the dialysis bag into a 30% volume fraction of ethanol solution for 3 times of dialysis, each dialysis for 4 to 5 hours to remove unreacted 4-amino Tempo, HDI and DMSO molecular. After dialysis, the mixed samples were taken out and freeze-dried, pre-frozen in a -20°C refrigerator for 12 hours, then taken out and dried in a freeze dryer for 48 hours to obtain the desired spin-labeled cornstarch.

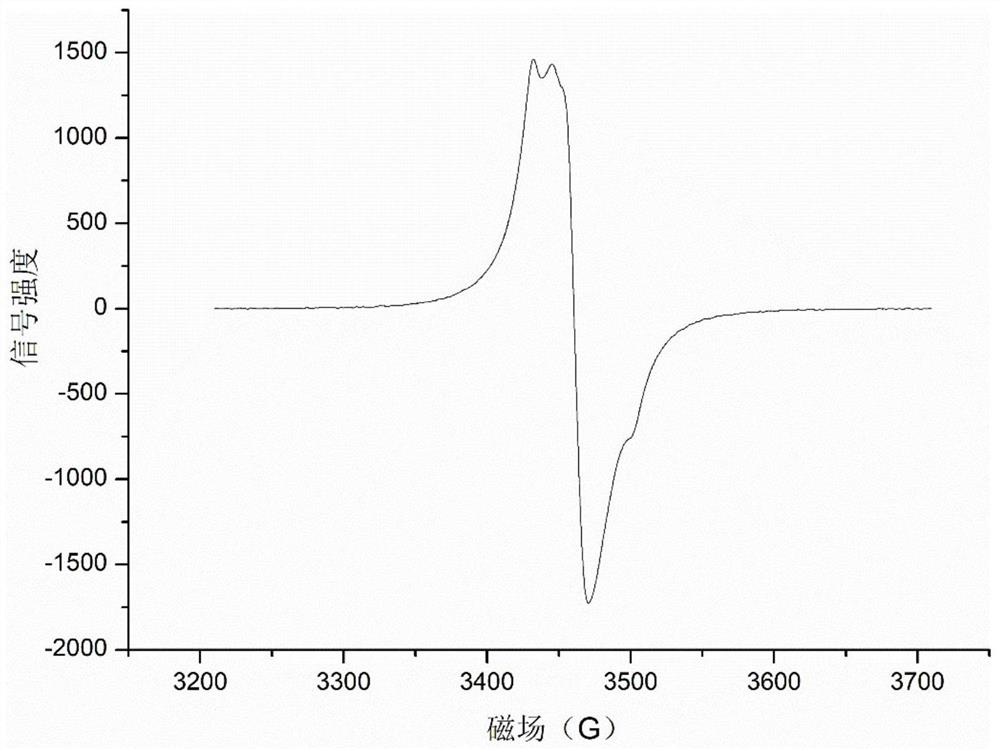

[0041] Take 50 mg of spin-labeled cornstarch in a quartz tube for electron paramagnetic resonance (EPR)...

Embodiment 2

[0044] 2.0 g of amylose was added to 35 mL of anhydrous DMSO and dissolved at 25 °C for 10 h to prepare a starch solution for later use. Dissolve 1 g of hexamethyl diisocyanate and 10 mg of 4-amino Tempo in 10 mL of DMSO, and after continuous stirring for 2 h, mix it with the above starch solution and continue stirring for 24 h to obtain a mixed sample.

[0045] Use a dialysis bag with a molecular weight of 8000-16000 to hold the mixed sample and seal it, then submerge the dialysis bag into a 30% volume fraction of ethanol solution for 3 times of dialysis, each dialysis for 4 to 5 hours to remove unreacted 4-amino Tempo, HDI and DMSO molecular. After the dialysis, the mixed sample was taken out and freeze-dried. It was pre-frozen in a -20°C refrigerator for 12 hours, and then taken out and dried in a freeze dryer for 48 hours to finally obtain the desired spin-labeled amylose.

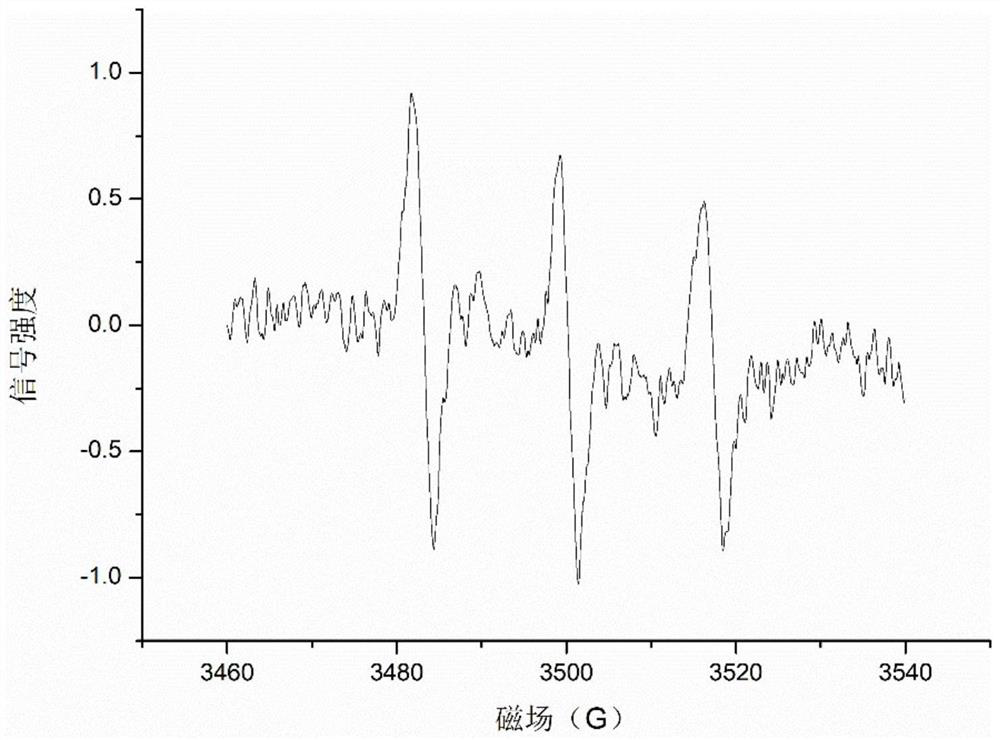

[0046] Take 50mg of spin-labeled amylose in a quartz tube for electron paramagnetic resonance (EPR...

Embodiment 3

[0049] 2.0 g of wheat starch was added to 35 mL of anhydrous DMSO and dissolved at 25 °C for 10 h to prepare a starch solution for later use. Dissolve 1 g of hexamethyl diisocyanate and 80 mg of 4-amino Tempo in 10 mL of anhydrous DMSO, and after continuous stirring for 2 h, mix it with the above starch solution and continue stirring for 24 h to obtain a mixed sample.

[0050]Use a dialysis bag with a molecular weight of 8000-16000 to hold the mixed sample and seal it, then submerge the dialysis bag into a 30% volume fraction of ethanol solution for 3 times of dialysis, each dialysis for 4 to 5 hours to remove unreacted 4-amino Tempo, HDI and DMSO molecular. After the dialysis, the mixed samples were taken out and freeze-dried. They were pre-frozen in a -20°C refrigerator for 12 hours, then taken out and dried in a freeze dryer for 48 hours to finally obtain the desired spin-labeled wheat starch.

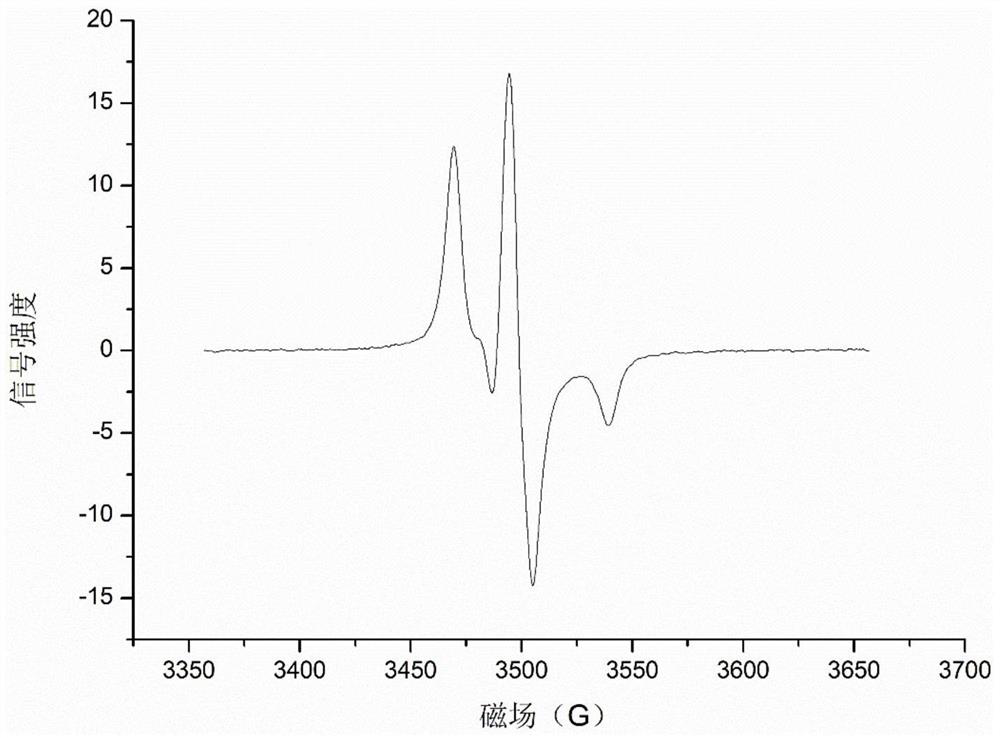

[0051] Take 50 mg of spin-labeled wheat starch in a quartz tube for electron p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com