Low-release non-sensitization odorless acrylic emulsion, interior wall coating and preparation method of low-release non-sensitization odorless acrylic emulsion

A technology of odor-cleaning acrylic and interior wall coatings, applied in the field of latex paint, can solve the problems of high allergens and high VOC content, and achieve the effect of low VOC content and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

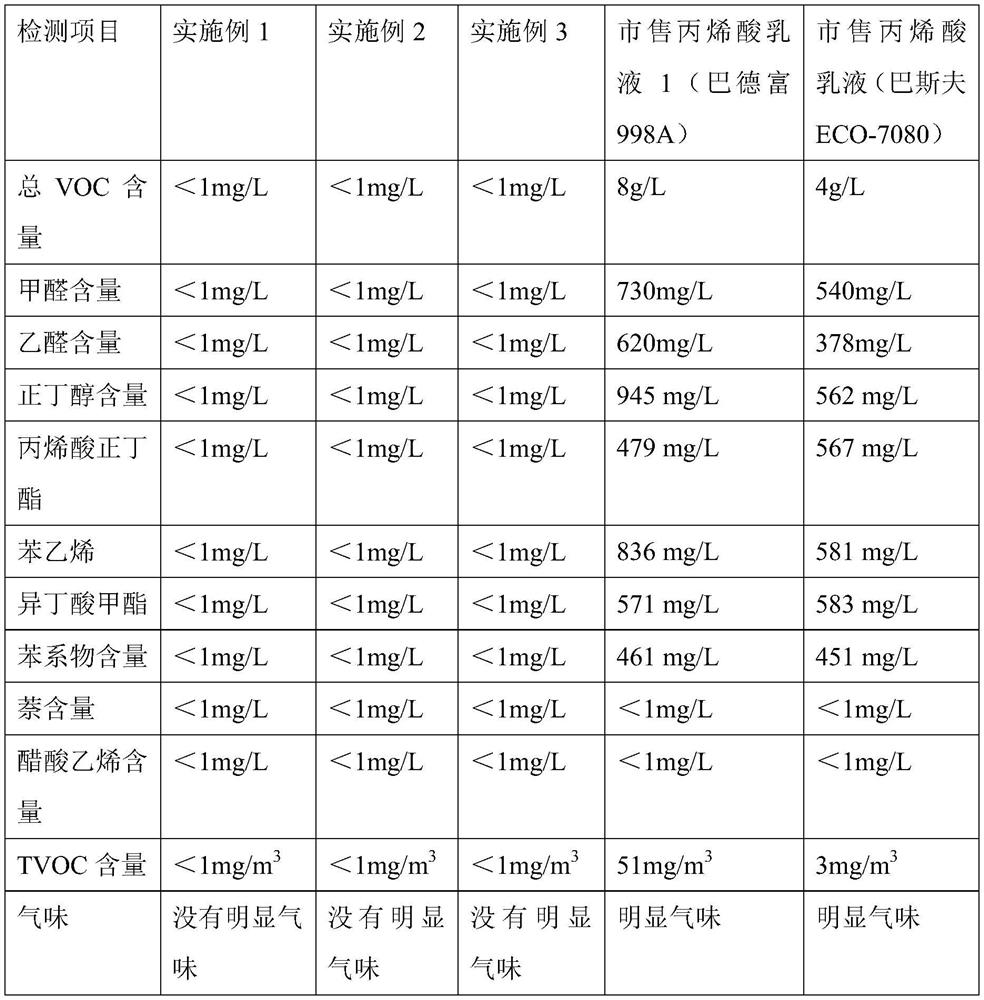

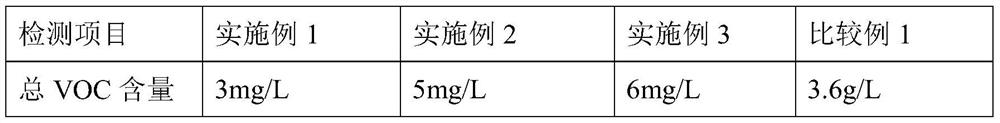

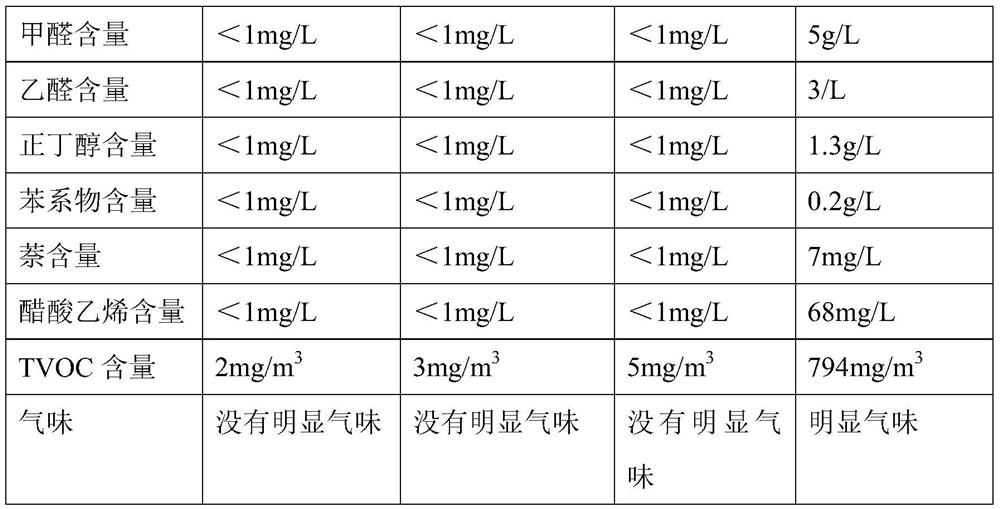

Examples

preparation example Construction

[0048] The present embodiment also provides a preparation method of the above-mentioned clean taste acrylic emulsion, comprising:

[0049] Mix tert-butyl methacrylate, n-hexyl acrylate, ethyl methacrylate, methacrylic acid and polydimethylsiloxane, add an initiator to polymerize at 85-90°C to obtain a water-based polymer emulsion, and use water vapor Purify.

[0050] Further, the preparation method of above-mentioned aqueous polymer emulsion specifically comprises:

[0051] Step S1: combine 3-8 parts of tert-butyl methacrylate, 10-15 parts of n-hexyl acrylate, ethyl methacrylate, methacrylic acid, polydimethylsiloxane, initiator and The emulsifiers are mixed to obtain a pre-emulsion.

[0052] Preferably, also comprise the step of preparing seed emulsion:

[0053] Step S2: add 30-50 parts of water and 1-2 parts of emulsifier into another container, stir and dissolve fully, heat up to 85-90°C, and slowly dropwise add the pre-emulsification prepared in step S1 with a mass frac...

Embodiment 1

[0079] The present embodiment provides a low-release and non-sensitizing clean-flavored acrylic emulsion, the raw materials of which include in parts by weight:

[0080] 12 parts of tert-butyl methacrylate, 24 parts of n-hexyl acrylate, 3 parts of ethyl methacrylate, 5 parts of methacrylic acid, 1 part of polydimethylsiloxane, 0.2 parts of potassium peroxide, 3 parts of emulsifier, 0.1 part of oxidizing agent, 0.1 part of reducing agent, 3 parts of pH adjuster, and 130 parts of water.

[0081] Among them, the emulsifier is polyoxyethylene silane; the oxidizing agent is persulfate; the reducing agent is sodium sulfite; the pH adjusting agent is sodium hydroxide

[0082] The preparation method of this taste-free acrylic emulsion includes:

[0083] (1) Under normal temperature and pressure, add 1 part of emulsifier and 50 parts of water in container A, disperse and stir until fully mixed, then add 3 parts of tert-butyl methacrylate and 10 parts of n-hexyl acrylate successively. ...

Embodiment 2

[0090] The present embodiment provides a low-release and non-sensitizing clean-flavored acrylic emulsion, the raw materials of which include by weight:

[0091] 14 parts of tert-butyl methacrylate, 23 parts of n-hexyl acrylate, 6 parts of ethyl methacrylate, 2 parts of methacrylic acid, 2 parts of polydimethylsiloxane, 0.3 parts of potassium peroxide, 5 parts of emulsifier, 0.2 part of oxidizing agent, 0.2 part of reducing agent, 5 parts of pH adjuster, and 150 parts of water.

[0092] Among them, the emulsifier is polyoxyethylene silane; the oxidizing agent is persulfate; the reducing agent is sodium sulfite; the pH adjusting agent is sodium hydroxide

[0093] The preparation method of this taste-free acrylic emulsion includes:

[0094](1) Under normal temperature and pressure, add 2 parts of emulsifier and 60 parts of water in container A, disperse and stir until fully mixed, then add 8 parts of tert-butyl methacrylate and 15 parts of n-hexyl acrylate successively, the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com