Preparation method of Co9S8 quantum dot in-situ embedded CoNi-LDH electrode material

A technology of electrode materials and quantum dots, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of slow volume change, ion diffusion, high electrochemical performance, etc., and achieve the effects of easy exposure, good electrochemical capacity performance, and promotion of superelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

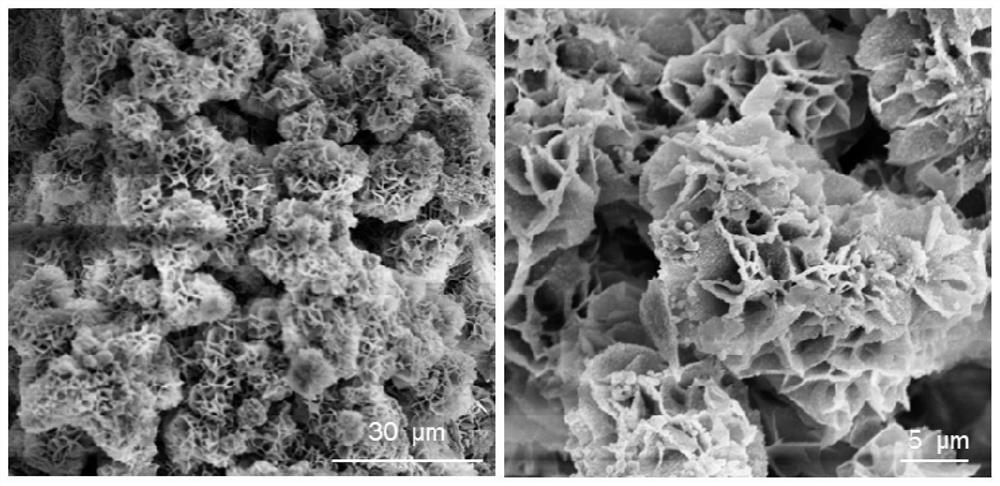

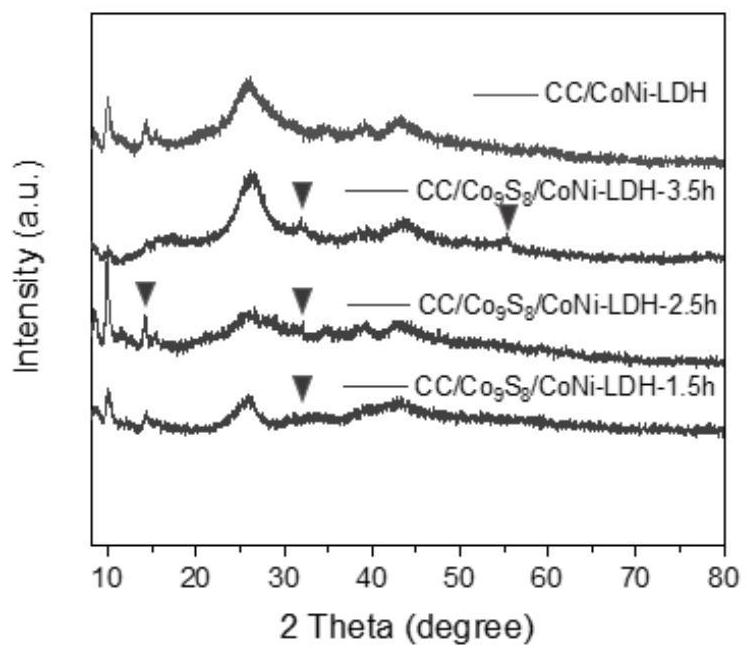

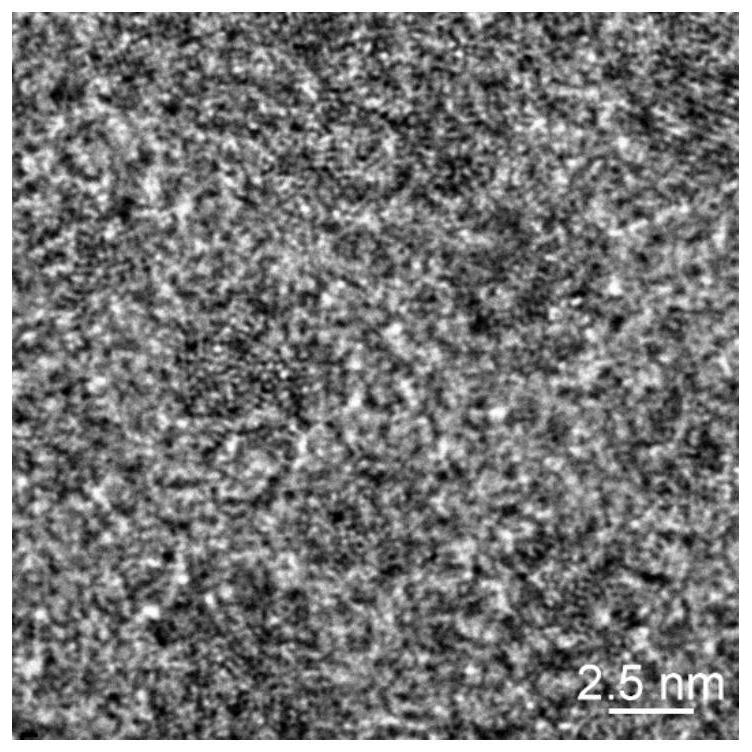

Image

Examples

Embodiment 1

[0044] Step 1. Processing of carbon cloth: First, cut the carbon cloth to 2cm 2 Then the carbon was placed in the lining of a polytetrafluoroethylene reaction kettle containing concentrated nitric acid solution, and it was completely sealed and placed in an oven. The oven temperature was kept at 100 °C and kept for 1 h. After cooling down naturally, use acetone, deionized water, and absolute ethanol for repeated ultrasonic cleaning for 30 minutes, dry at room temperature, and let stand for later use;

[0045] Step 2. Nickel nitrate hexahydrate (Ni(NO) 3 ) 2 ·6H 2 O, 0.9g, 0.003mol), the organic ligand 1,3,5-benzenetricarboxylic acid (H 3 BTC, 0.9g, 0.004mol), N,N-dimethylformamide (DMF, 48mL), mixed and stirred at room temperature for 30min to obtain mixed solution A;

[0046] Step 3. Transfer the mixed solution A obtained in step 2 into a polytetrafluoroethylene reaction kettle, then put it into an oven, react at 120 °C for 24 hours, and then heat at 5 °C for min -1 The ...

Embodiment 2

[0051] Step 1. Processing of carbon cloth: First, cut the carbon cloth to 2cm 2 Then, the carbon was placed in the lining of the polytetrafluoroethylene reaction kettle containing concentrated nitric acid solution, and it was completely sealed and placed in an oven. The oven temperature was kept at 140 °C and kept for 4 h. After cooling down naturally, use acetone, deionized water, and absolute ethanol for repeated ultrasonic cleaning for 30 minutes, dry at room temperature, and let stand for later use;

[0052] Step 2. Nickel nitrate hexahydrate (Ni(NO) 3 ) 2 ·6H 2 O, 0.9g, 0.003mol), the organic ligand 1,3,5-benzenetricarboxylic acid (H 3 BTC, 0.9g, 0.004mol), N,N-dimethylformamide (DMF, 48mL), mixed and stirred at room temperature for 30min to obtain mixed solution A;

[0053] Step 3. Transfer the mixed solution A obtained in step 2 into a polytetrafluoroethylene reaction kettle, then put it into an oven, react at 120 °C for 24 hours, and then heat at 5 °C for min -1 T...

Embodiment 3

[0059] Step 1. Processing of carbon cloth: First, cut the carbon cloth to 2cm 2 Then, the carbon was placed in the lining of the polytetrafluoroethylene reaction kettle containing concentrated nitric acid solution, and it was completely sealed and placed in an oven. The oven temperature was kept at 100 °C and kept for 2 h. After cooling down naturally, use acetone, deionized water, and absolute ethanol for repeated ultrasonic cleaning for 30 minutes, dry at room temperature, and let stand for later use;

[0060] Step 2. Nickel nitrate hexahydrate (Ni(NO) 3 ) 2 ·6H 2 O, 0.9g, 0.003mol), the organic ligand 1,3,5-benzenetricarboxylic acid (H 3 BTC, 0.9 g, 0.004 mol), N,N-dimethylformamide (DMF, 48 mL), mixed and stirred at room temperature for 30 min to obtain mixed solution A.

[0061] Step 3. Transfer the mixed solution A obtained in step 2 into a polytetrafluoroethylene reaction kettle, then put it into an oven, react at 120 °C for 24 hours, and then heat at 5 °C for min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com