Production method of coffee fresh fruit extract

A production method and extraction technology, which are applied in the production field of coffee fresh fruit extract, can solve the problems of uncontinuous production, long extraction time, low extraction yield, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

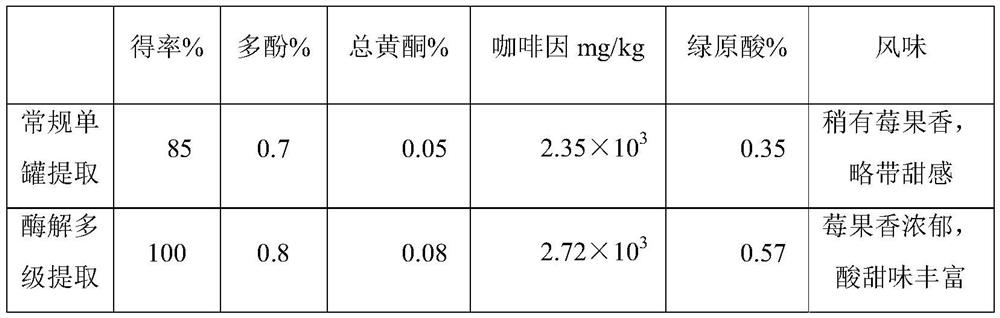

Embodiment 1

[0021] A production method of coffee fresh fruit extract, comprising the following steps:

[0022] 1) Yunnan Katim coffee fresh fruit pretreatment, using extrusion, shearing or homogenization, etc., to grind coffee fresh fruit into coffee pulp.

[0023] 2) After dissolving pectinase, hemicellulase, and beta-glucose, mix them into a composite enzyme; wherein, the mass of pectinase accounts for 20% of the mass of the composite enzyme, and the mass of hemicellulase accounts for 50% of the mass fraction of the composite enzyme, The mass of β-glucose enzyme accounted for 30% of the mass fraction of compound enzymes.

[0024] 3) Add the coffee pulp, compound enzyme and water into the first-level enzymatic hydrolysis extraction tank, and after the first-level enzymatic hydrolysis, go through the second-level high-temperature extraction and the third-level high-temperature extraction in sequence, and collect the extraction liquid;

[0025] In the first-level enzymolysis extraction ta...

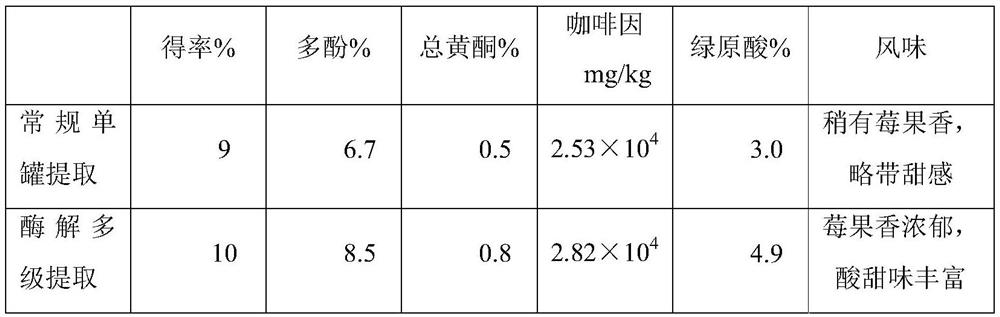

Embodiment 2

[0033] A production method of coffee fresh fruit extract, comprising the following steps:

[0034] 1) Hainan Xinglong coffee fresh fruit pretreatment, using extrusion, shearing or homogenization, etc., to grind the coffee fresh fruit into coffee pulp for use.

[0035] 2) After dissolving pectinase, hemicellulase and β-glucose, mix them into a composite enzyme; wherein, the mass of pectinase accounts for 30% of the mass fraction of the composite enzyme, and the mass of hemicellulase accounts for 40% of the mass fraction of the composite enzyme. %, the mass of β-glucose enzyme accounted for 30% of the mass fraction of compound enzymes.

[0036] 3) Add the coffee pulp, compound enzyme and water into the first-level enzymatic hydrolysis extraction tank, and after the first-level enzymatic hydrolysis, go through the second-level high-temperature extraction and the third-level high-temperature extraction in sequence, and collect the extraction liquid;

[0037] In the primary enzymo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com