Precious metal/carbon nanosheet composite material and preparation method thereof

A technology of carbon nanosheets and composite materials, which is applied in the field of noble metal/carbon nanosheet composite materials and their preparation, can solve the problems of narrow particle size distribution, waste of precious metal raw materials, and low utilization rate of raw materials, and achieve high loading of precious metals, combined Strong and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of noble metal / carbon nanosheet composite material, which is prepared by the following steps:

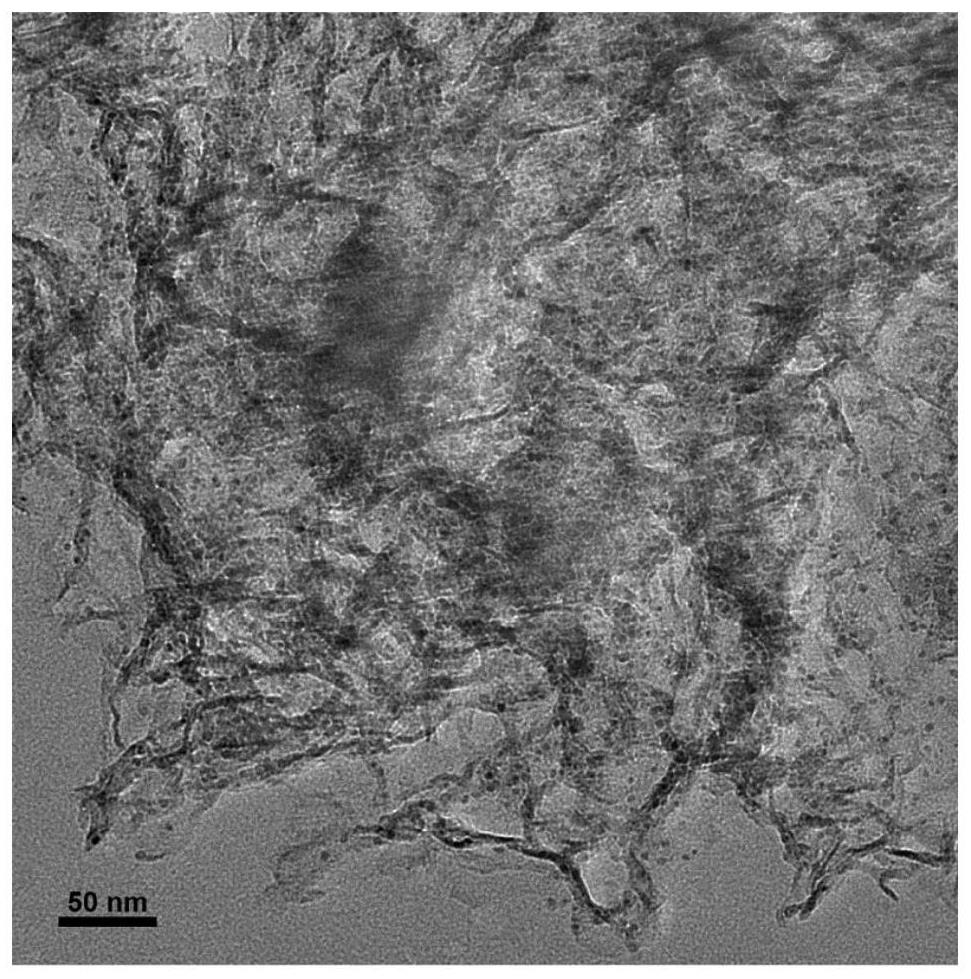

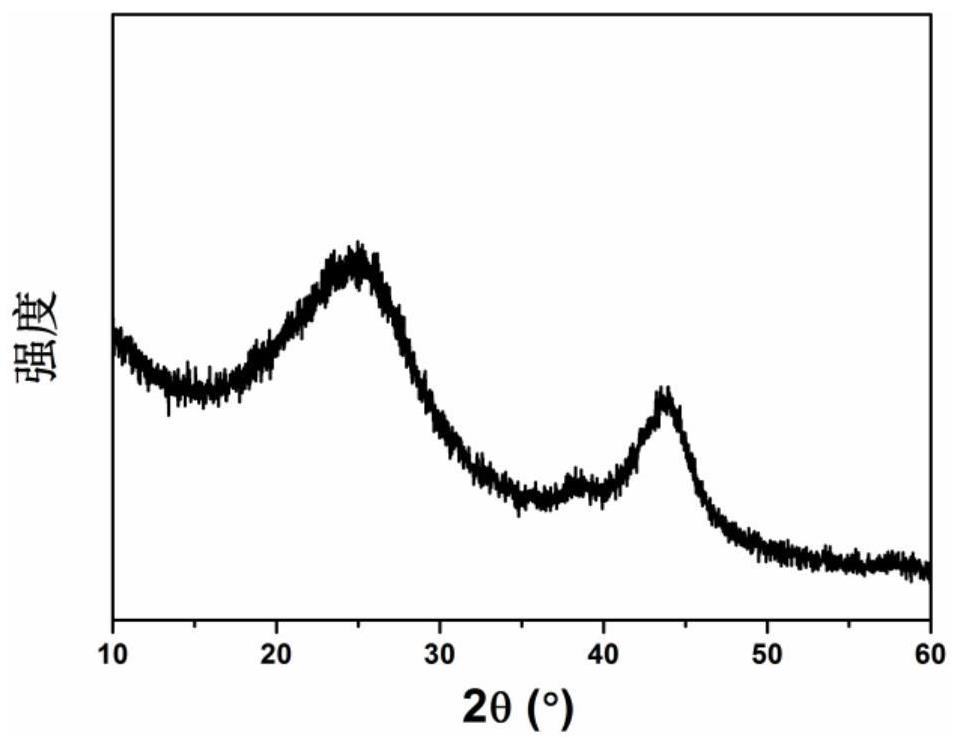

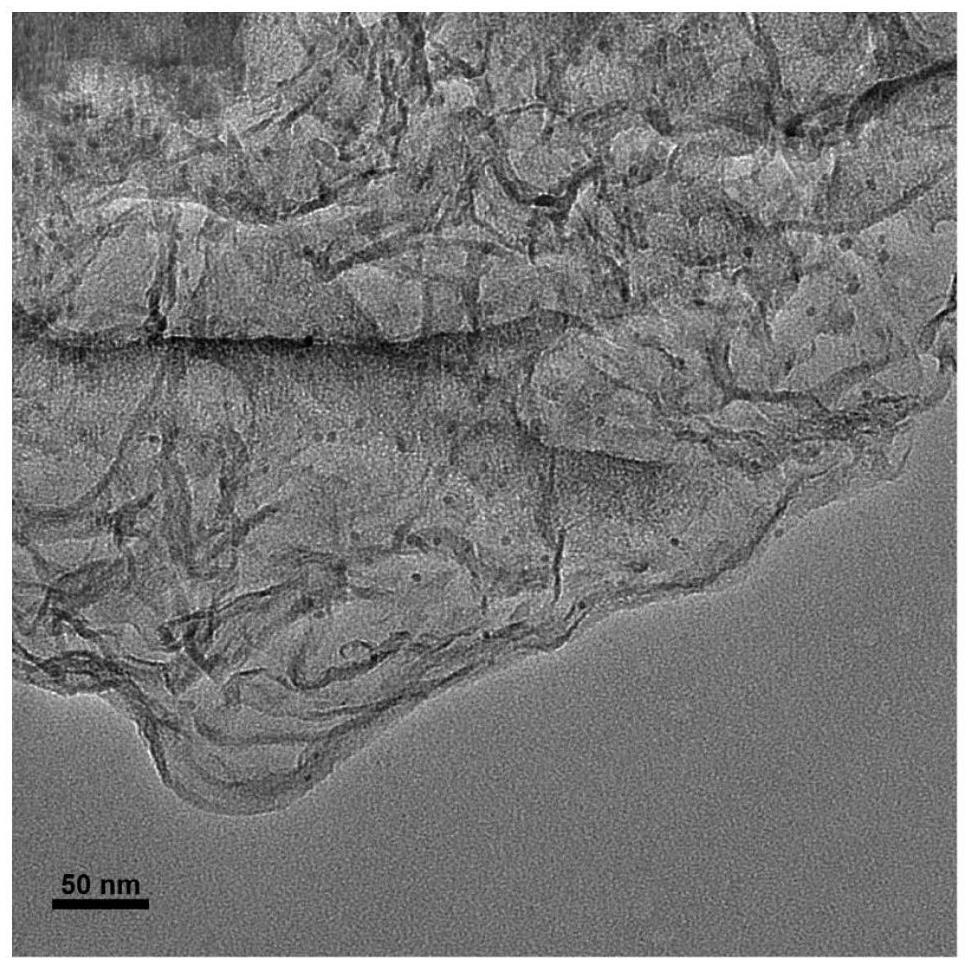

[0040] (1) after 120g of urea, 10g of polyvinylpyrrolidone and 2.0g of ruthenium trichloride were mixed uniformly, heated to 200°C, stirred for 4h until completely solid, naturally cooled to room temperature to obtain a precursor; (2) the obtained precursor was Put it into a tube furnace, under the protection of argon, control the heating rate to be 4 °C / min, heat it up to 900 °C, keep it for 2 hours, and then naturally cool to room temperature to obtain a ruthenium / carbon nanosheet composite material, and the obtained ruthenium / carbon nanosheets The mass fraction of ruthenium in the sheet composite is 20%.

Embodiment 2

[0042] A preparation method of noble metal / carbon nanosheet composite material, which is prepared by the following steps:

[0043] (1) after 100g of urea, 8.0g of polyvinylpyrrolidone and 1.0g of ruthenium trichloride were mixed uniformly, heated to 190° C., stirred for 2h until completely solid, naturally cooled to room temperature to obtain a precursor; (2) the obtained precursor was The ruthenium / carbon nanosheet composite material was obtained, and the temperature was increased to 1000°C under the protection of nitrogen, and the temperature was increased to 1000°C. The mass fraction of ruthenium in the sheet composite material is 10%.

Embodiment 3

[0045] A preparation method of noble metal / carbon nanosheet composite material, which is prepared by the following steps:

[0046] (1) after 90g of urea, 6g of polyvinylpyrrolidone and 0.4g of ruthenium trichloride were mixed uniformly, heated to 230° C., stirred for 6h until completely solid, naturally cooled to room temperature to obtain a precursor; (2) the obtained precursor was Put it into a tube furnace, under nitrogen protection, control the heating rate to be 3°C / min, heat up to 900°C, keep warm for 4 hours, and then naturally cool to room temperature to obtain a ruthenium / carbon nanosheet composite material, and the obtained ruthenium / carbon nanosheet The mass fraction of ruthenium in the composite material is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com