Preparation method of feed-grade calcium formate

A calcium formate, feed-grade technology, applied in the agricultural field, can solve the problems of poor filtration effect, poor capture effect, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of feed grade calcium formate, the operation steps are:

[0033] 110g of formic acid was added to the reactor, and 100g of calcium carbonate powder was added while stirring; after 1h of reaction, lime milk was added to adjust the pH to 7-8, and the temperature was kept for 1h; then 2g of precipitant was added for precipitation, and filtered; Centrifugal separation and drying to obtain calcium formate; the mother liquor is recycled.

[0034] The mass concentration of the formic acid is 40%.

[0035] The calcium carbonate powder is put into batches to make the reaction proceed smoothly, so as to prevent the reaction liquid from overflowing the reaction tank and reduce the loss of formic acid.

[0036] The reaction temperature was at 85°C.

[0037] The drying temperature was 75°C.

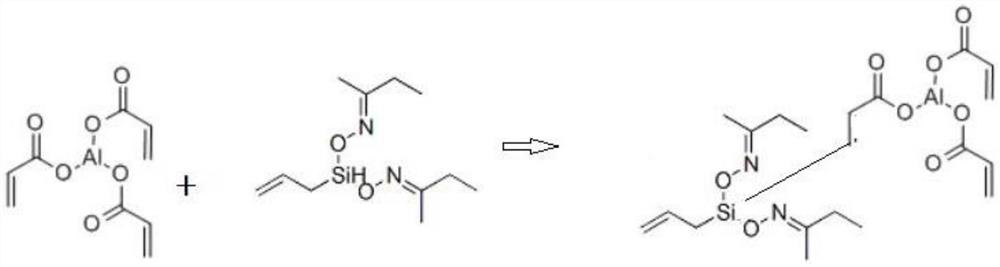

[0038] The preparation method of described precipitant is:

[0039] 13g of aluminum acrylate, 100g of toluene, 10g of vinylmethylbis(butanone oxime) silane, 0.02g of KA...

Embodiment 2

[0045] A preparation method of feed grade calcium formate, the operation steps are:

[0046] 115g of formic acid was added to the reactor, and 100g of calcium carbonate powder was added while stirring; after 1.5h of reaction, lime milk was added to adjust the pH to 7-8, and the temperature was kept for 1.5h; then 3g of precipitant was added for precipitation, and filtered; the filtrate was concentrated Crystallization, centrifugal separation, and drying to obtain calcium formate; the mother liquor is recycled.

[0047] The mass concentration of the formic acid was 44%.

[0048] The calcium carbonate powder is put into batches to make the reaction proceed smoothly, so as to prevent the reaction liquid from overflowing the reaction tank and reduce the loss of formic acid.

[0049] The reaction temperature was at 88°C.

[0050] The drying temperature was 78°C.

[0051] The preparation method of described precipitant is:

Embodiment 3

[0058] A preparation method of feed grade calcium formate, the operation steps are:

[0059] 118g of formic acid was added to the reactor, and 100g of calcium carbonate powder was added while stirring; after 1.5h of reaction, 18g of lime milk was added to adjust the pH to 7-8, and the temperature was kept for 2.5h; then 5g of precipitant was added for precipitation, and the filtrate was filtered; Concentrating and crystallizing, centrifuging and drying to obtain calcium formate; the mother liquor is recycled.

[0060] The mass concentration of the formic acid was 46%.

[0061] Described formic acid and calcium carbonate, the precipitant feeding amount is 1.18:1:0.05 by mass ratio.

[0062] The calcium carbonate powder is put into batches to make the reaction proceed smoothly, so as to prevent the reaction liquid from overflowing the reaction tank and reduce the loss of formic acid.

[0063] The reaction temperature was at 93°C.

[0064] The drying temperature was 82°C.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com