Anti-bacterial algae adhesion coating for concrete

An antibacterial algae and concrete technology, applied in antifouling/underwater coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of bacteria and algae invasion and adhesion, and achieve economic convenience, high smoothness, and wide application fields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of antibacterial algae-attached coating for concrete, the following raw materials are prepared by weight: 20 parts of sodium silicate, 15 parts of potassium silicate, 2 parts of sodium stearate, 1 part of propylene glycol butyl ether, 0.4 part of polysiloxane, 3 parts of sodium nitrate, water reducing agent: 1 part of PNS, 20 parts of polymer emulsion (polyvinyl acetate), 2 parts of superfine cement powder, 0.5 part of OIT, 1 part of Diuron.

[0022] Preparation of coatings: Press sodium silicate, potassium silicate, polysiloxane, propylene glycol butyl ether, nitrite, naphthalene sulfonate water reducer, OIT, Diuron, sodium stearate, polymer emulsion, ultrafine cement The powders were added in sequence for mixing, and after mixing uniformly, 35 parts of water were added and stirred uniformly to obtain a coating.

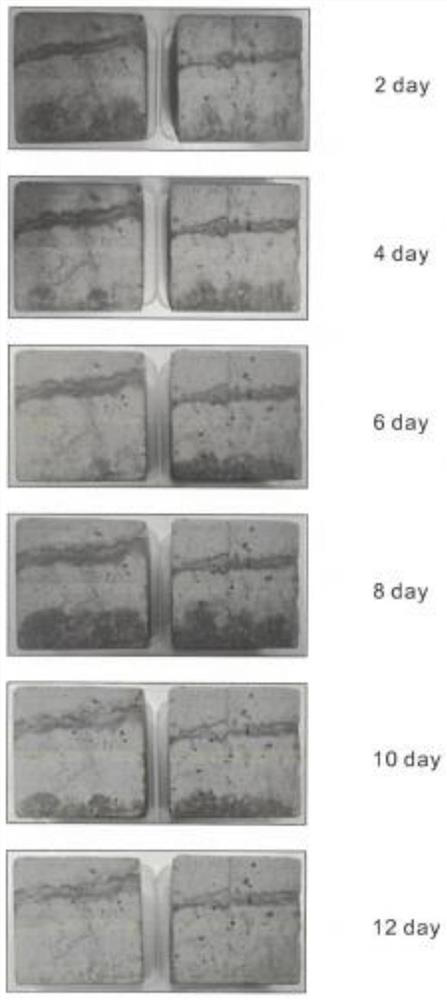

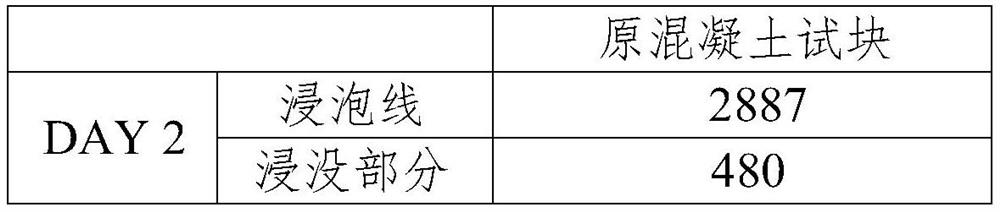

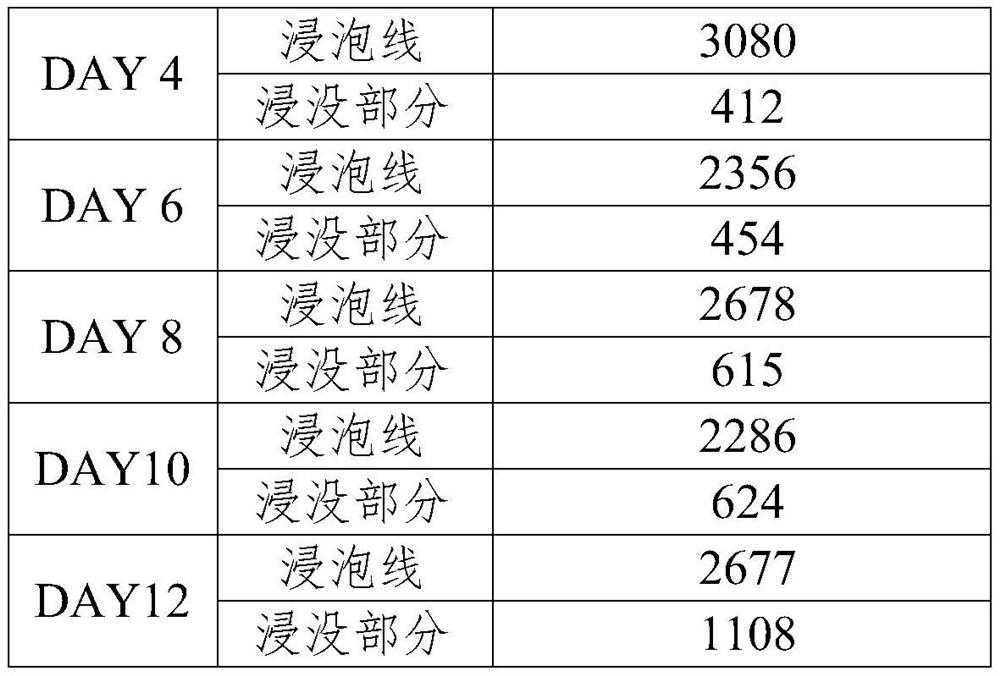

[0023] Apply the paint obtained above on the concrete test block of 100mm×100mm×100mm, and the paint can evenly cover the surface of the test block. ...

Embodiment 2

[0041] A kind of antibacterial algae-attached coating for concrete, the following raw materials are prepared by weight: 20 parts of sodium silicate, 15 parts of potassium silicate, 2 parts of sodium stearate, 1 part of propylene glycol butyl ether, 0.4 part of polysiloxane, 3 parts of sodium nitrate, water reducing agent naphthalene sulfonate water reducing agent: 1 part of PNS, 20 parts of polyvinyl acetate, 2 parts of superfine cement powder, 1 part of OIT, 0.5 part of Diuron.

[0042] Preparation of coatings: Press sodium silicate, potassium silicate, polysiloxane, propylene glycol butyl ether, sodium nitrite, naphthalene sulfonate water reducer, OIT, Diuron, sodium stearate, polyvinyl acetate, ultrafine The cement powder was added in sequence for mixing, and after mixing, 35 parts of water was added and stirred evenly to obtain a coating.

[0043]The paint obtained above was evenly spread on a concrete test block of 100mm×100mm×100mm.

[0044] The detection method is the ...

Embodiment 3

[0048] A kind of antibacterial algae-attached coating for concrete, the following raw materials are prepared by weight: 20 parts of sodium silicate, 15 parts of potassium silicate, 2 parts of sodium stearate, 1 part of propylene glycol butyl ether, 0.4 part of polysiloxane, 3 parts of potassium nitrate, water reducing agent: 1 part of PNS, 20 parts of polyvinyl acetate, 2 parts of superfine cement powder, 0.7 part of OIT, 0.7 part of Diuron.

[0049] Preparation of coating: Sodium silicate, potassium silicate, polysiloxane, propylene glycol butyl ether, potassium nitrite, PNS, OIT, Diuron, sodium stearate, polyvinyl acetate, superfine cement powder are added in order Mix. After mixing, add 35 parts of water and stir to obtain a coating.

[0050] The paint obtained above was applied to a concrete test block of 100 mm×100 mm×100 mm.

[0051] The detection method is the same as that in Example 1, and the measurement results are as in 3.

[0052] table 3

[0053]

[0054] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com