Preparation process of amino acid modified ethylene-vinyl alcohol copolymer nanofiber membrane

A vinyl alcohol copolymer, nanofiber membrane technology, applied in the directions of fiber treatment, fiber type, fiber chemical characteristics, etc., can solve the problems of unseen-COOH grafted polymer fiber membrane, etc., and achieves the benefits of recycling and reuse, The effect of reducing steric hindrance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Dissolve 0.74 g EVOH in 10 mL of a mixed solvent of isopropanol and deionized water (7 / 3, v / v), stir at 65°C until EVOH is completely dissolved;

Withdraw 3 mL of the spinning solution with a syringe with a needle and place it on a microsyringe pump.

[0025] Adjust the spinning voltage to 17 kV and the flow rate to 0.6 mL h -1 , the receiving distance is 15 cm, and after about 8 hours, EVOH NFM with a certain thickness can be obtained.

[0026] The EVOH NFM was immersed in 10 % arginine solution, polyphosphoric acid was added as a catalyst, and the reaction was carried out at 85 °C for 30 min to obtain arginine-modified EVOH (EVOH-ARG) NFM.

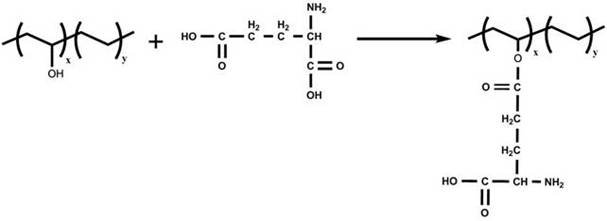

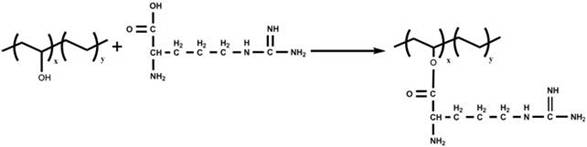

[0027] The reaction equation for arginine-modified EVOH is as follows:

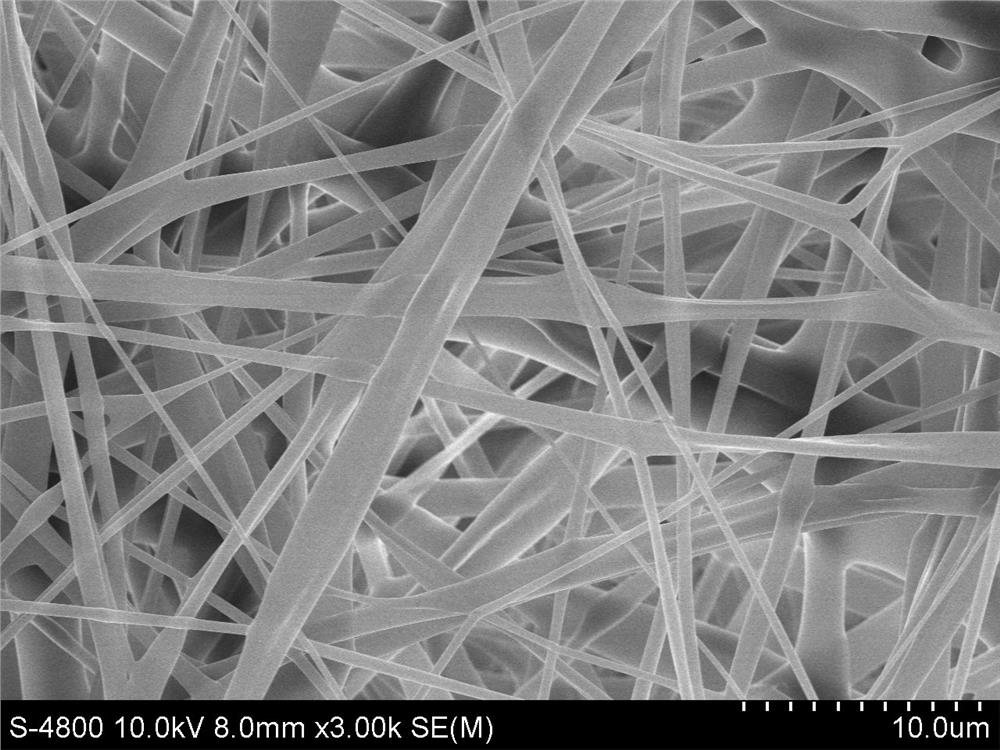

The pure EVOH nanofiber membrane has a smooth surface, uniform thickness and good fiber morphology. After the grafting of arginine, the fibers appeared obvious merging phenomenon, and the fibers became flat. As shown in Figure 1.

[0028] Since the adsorbed C...

Embodiment 2

Dissolve 0.74 g EVOH in 10 mL of a mixed solvent of isopropanol and deionized water (7 / 3, v / v), stir at 65°C until EVOH is completely dissolved;

Withdraw 3 mL of the spinning solution with a syringe with a needle and place it on a microsyringe pump.

[0031] Adjust the spinning voltage to 17 kV and the flow rate to 0.6 mL h -1 , the receiving distance is 15 cm, and after about 8 hours, EVOH NFM with a certain thickness can be obtained.

[0032] The EVOH NFM was immersed in 20 % glutamic acid solution, and polyphosphoric acid was added as a catalyst to react at 95 °C for 120 min to obtain glutamic acid-modified EVOH (EVOH-GLU) NFM.

[0033] The reaction equation for the modification of EVOH with glutamate is as follows:

The reaction temperature has a great influence on the fiber morphology, as shown in Figure 4. The diameter of EVOH NFM fibers modified by GLU was obviously thicker, and the fibers became denser. This phenomenon became more and more obvious with the incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com