Formed lead-acid battery for starting

A lead-acid battery, lead-calcium technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of forgetting formed batteries, low specific energy of planté batteries, etc., to reduce equipment investment and energy consumption, and reduce carbon emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

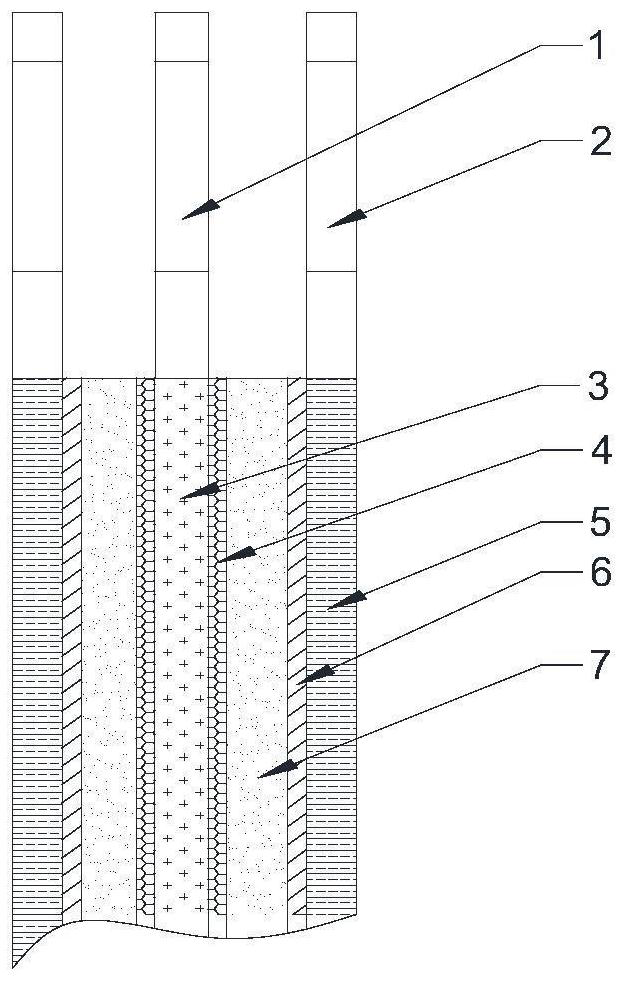

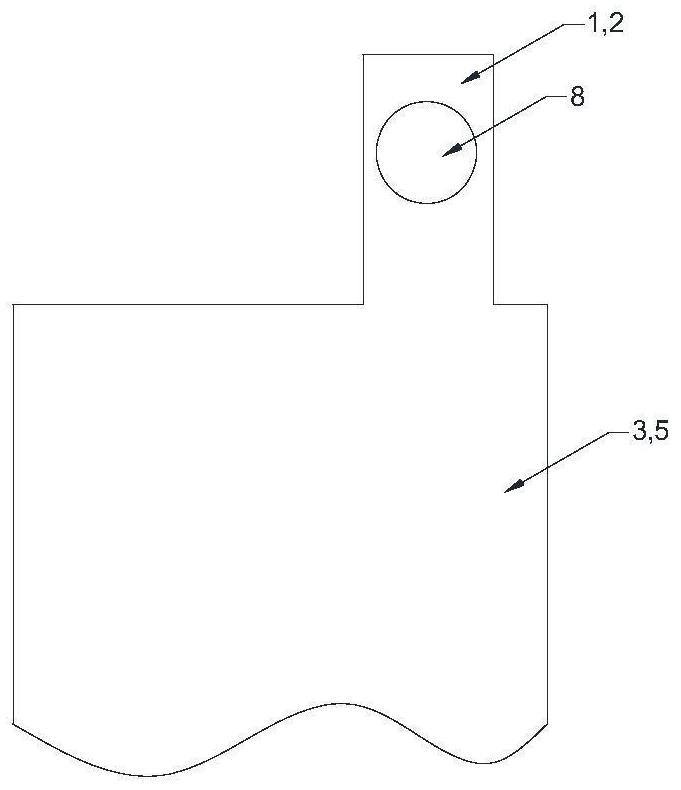

[0037] according to figure 2 A lead-antimony alloy cathode substrate 3 with an antimony content of 3.5% with a thickness of 0.5mm, lead-calcium-tin-aluminum (lead-calcium-tin-aluminum) with a thickness of 0.4mm (calcium 0.07%, tin 1.2%, aluminum 0.04%, lead balance) lead-calcium The tin-aluminum negative electrode base 5 has a width of 60mm and a height of 60mm. The width of the plate ears 1 and 2 is 10mm and the height is 10mm. The radius of the connection hole 8 is 3mm.

[0038] Do the following in sequence:

[0039] (1) Put it into the sodium hydroxide hot alkali at 80°C for ultrasonic degreasing for 8h, and clean it completely with deionized water for 5min;

[0040] (2) Cathode etching: using a three-electrode system, the substrates 3 and 5 are working batteries, Hg / Hg 2 SO 4 / H 2 SO 4 The electrode is the reference electrode, the lead plate is the counter electrode, the specific gravity of the sulfuric acid electrolyte is 1.28g / mL, the cathode is etched for 5h under...

Embodiment 2

[0060] according to figure 2 The cutting size of the structure is 14.5cm (W) × 11.7cm (H), the thickness of 0.1mm lead-antimony (sb3.5%) matrix 3 and the thickness of 0.15mm lead-calcium-tin-aluminum (calcium 0.07%, tin 1.2%, aluminum 0.04%, lead allowance) of the base body 5, the width of the lugs 1, 2 is 15mm, the height is 16mm, and the radius of the connecting hole 8 is 3mm.

[0061] Do the following in sequence:

[0062] (1) Put it into the sodium hydroxide hot alkali at 80°C for ultrasonic degreasing for 8h, and clean it completely with deionized water for 5min;

[0063] (2) Cathode etching: using a three-electrode system, the substrates 3 and 5 are working cells, Hg / Hg2SO 4 / H 2 SO 4 The electrode is the reference electrode, the lead plate is the counter electrode, the specific gravity of the sulfuric acid electrolyte is 1.28g / mL, the cathode is etched for 10h under the condition of constant potential -1.55V, and deionized water is completely cleaned;

[0064] (3)...

Embodiment 3

[0083] according to figure 2 A lead-antimony alloy cathode substrate 3 with an antimony content of 3.5% with a thickness of 0.3mm, lead-calcium-tin-aluminum with a thickness of 0.25mm (calcium 0.07%, tin 1.2%, aluminum 0.04%, lead balance) lead-calcium The tin-aluminum negative electrode base 5 has a width of 60mm and a height of 60mm. The width of the plate ears 1 and 2 is 12mm and the height is 14mm. The radius of the connection hole 8 is 3mm.

[0084] Do the following in sequence:

[0085] (1) Put it into the sodium hydroxide hot alkali at 80°C for ultrasonic degreasing for 8h, and clean it completely with deionized water for 5min;

[0086] (2) Cathode etching: using a three-electrode system, the substrates 3 and 5 are working batteries, Hg / Hg 2 SO 4 / H 2 SO 4 The electrode is the reference electrode, the lead plate is the counter electrode, the specific gravity of the sulfuric acid electrolyte is 1.28g / mL, the cathode is etched for 5h under the condition of constant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com