Electrolyte, positive electrode, lithium ion battery and vehicle

An electrolyte and lithium salt technology, applied in the field of new energy, can solve the problems of accelerating carbonate electrolyte, electrolyte consumption, deterioration, etc., and achieve the effects of improving cycle stability, maintaining stability, and improving elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

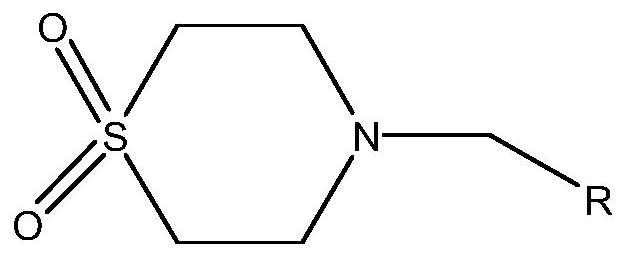

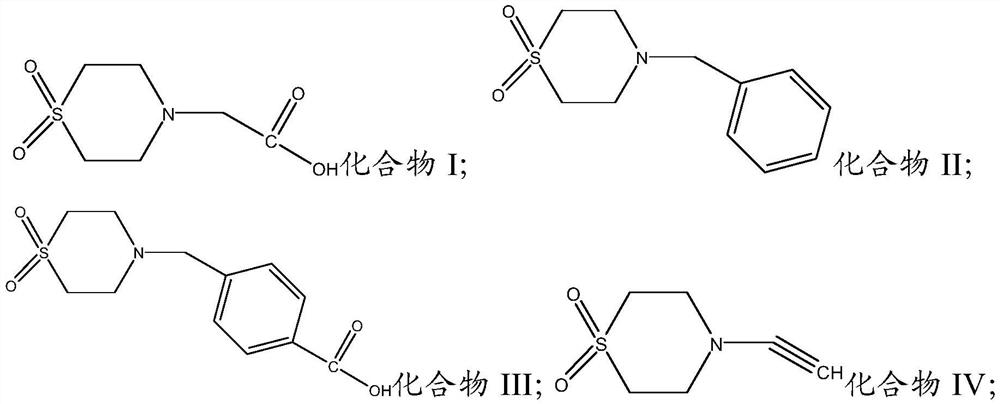

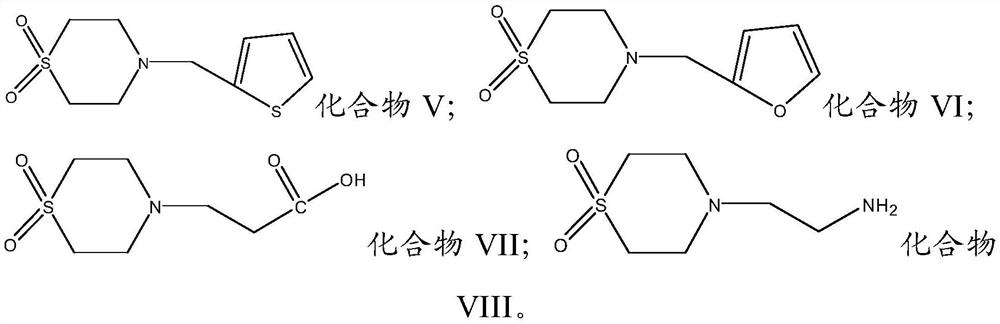

Method used

Image

Examples

preparation example Construction

[0062] (1) Preparation of electrolyte:

[0063] The vinyl carbonate and diethyl carbonate were mixed into a mixed solvent according to the mass ratio of 3:7, and lithium hexafluorophosphate (LiPF) was added to the mixed solvent 6 To a molar concentration of 1.0mol / L, and then add a second additive fluorovinyl carbonate and a first additive to it in turn, stirred evenly to give the electrolyte. The specific types of additives used in the electrolyte and their content are shown in Table 1, wherein the proportion of additives is a mass percentage accounting for the total mass of the electrolyte.

[0064] (2) Preparation of cathode sheets:

[0065] The mass ratio is 100:1:2:2 to LiNi 0.5 Co 0.2 Mn 0.3 O 2(NCM523), Super-P, CNT and polyvinylidene fluoride (PVDF) mixed into a uniform paste, evenly coated on the thickness of 20um aluminum foil, dried at 80 °C vacuum for 24h to obtain a positive electrode piece.

[0066] (3) Preparation of negative electrode sheet:

[0067] Mix graphite...

Embodiment 1

[0089] The battery test results of Example 1 and Example 7 show that the combination of alkyl thiomorpholine ring compound and different negative film-forming additives has a significant impact on the electrical performance of lithium-ion batteries, and the appropriate additive combination scheme has a certain effect on the further improvement of the partial electrical performance of lithium-ion batteries.

[0090] In summary, the electrolyte of the present application is conducive to forming an interface protective film at the positive electrode, thereby effectively inhibiting the dissolution of the positive metal ions and the oxidative decomposition of the electrolyte at high voltage; At the same time, it is also conducive to forming a stable SEI film on the surface of the negative electrode, maintaining the stability of the electrode / electrolyte interface, and further improving the cycle stability performance of the battery at high voltage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com