Ternary positive electrode precursor material, preparation method and ternary positive electrode material

A technology of positive electrode materials and precursors, applied in the field of battery materials, can solve the problems of low density, poor stability, affecting the cycle stability and energy density of ternary positive electrode materials, etc. The effect of volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

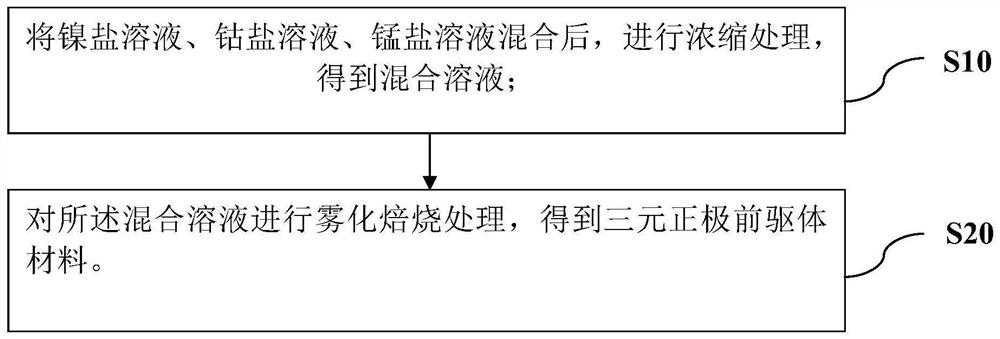

[0054] as attached image 3 As shown, a second aspect of the embodiments of the present application provides a method for preparing the above-mentioned ternary positive electrode precursor material, which includes the following steps:

[0055] S01. After mixing nickel salt solution, cobalt salt solution, and manganese salt solution, carry out concentration treatment to obtain mixed solution;

[0056] S02. Atomizing and roasting the mixed solution to obtain a ternary positive electrode precursor material.

[0057] The preparation method of the ternary positive electrode precursor material provided in the second aspect of the embodiment of the present application is based on Ni (1-y-z) Co y Mn z O x The stoichiometric ratio of metal elements in the general chemical formula, after mixing nickel salt solution, cobalt salt solution and manganese salt solution, the concentration of nickel salt, cobalt salt and manganese salt in the mixed solution is adjusted by concentration tre...

Embodiment 1

[0084] A hexagonal layered Ni 0.67 Co 0.05 Mn 0.28 O ternary cathode precursor material, its preparation includes steps:

[0085] ①According to Ni 0.67 Co 0.05 Mn 0.28 O the stoichiometric ratio of the metal elements in the chemical formula, after mixing the nickel chloride solution, the cobalt chloride solution and the manganese chloride solution, carry out concentration treatment to obtain a mixed solution; wherein the concentrations of nickel salt, cobalt salt and manganese salt are 163.7 g / L, 12.3g / L, 64.0g / L.

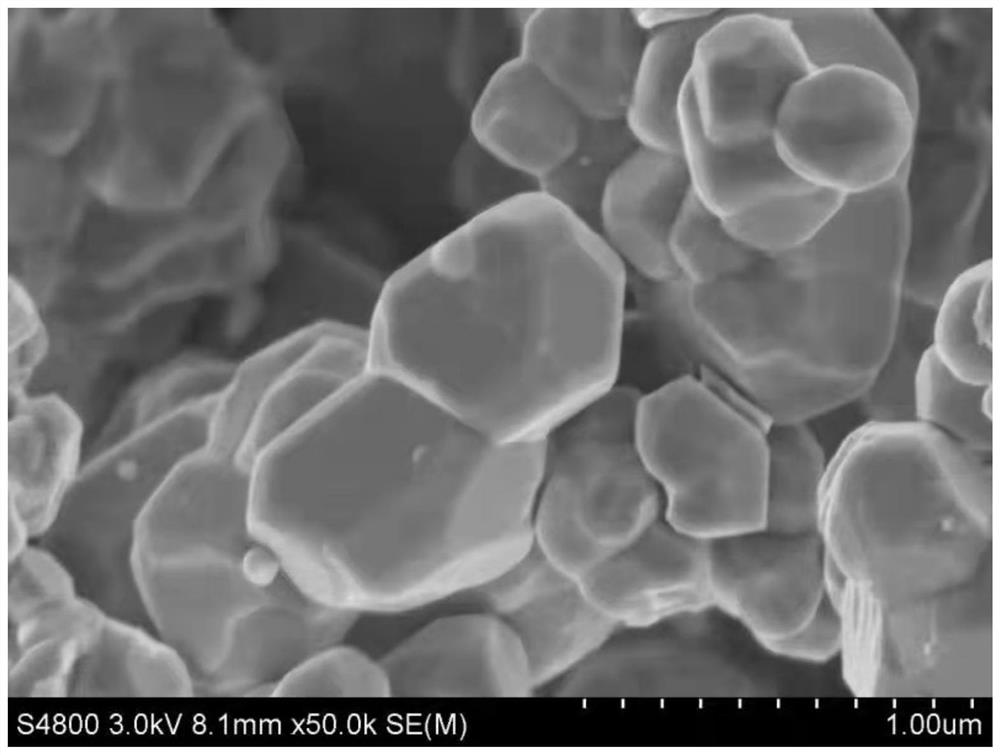

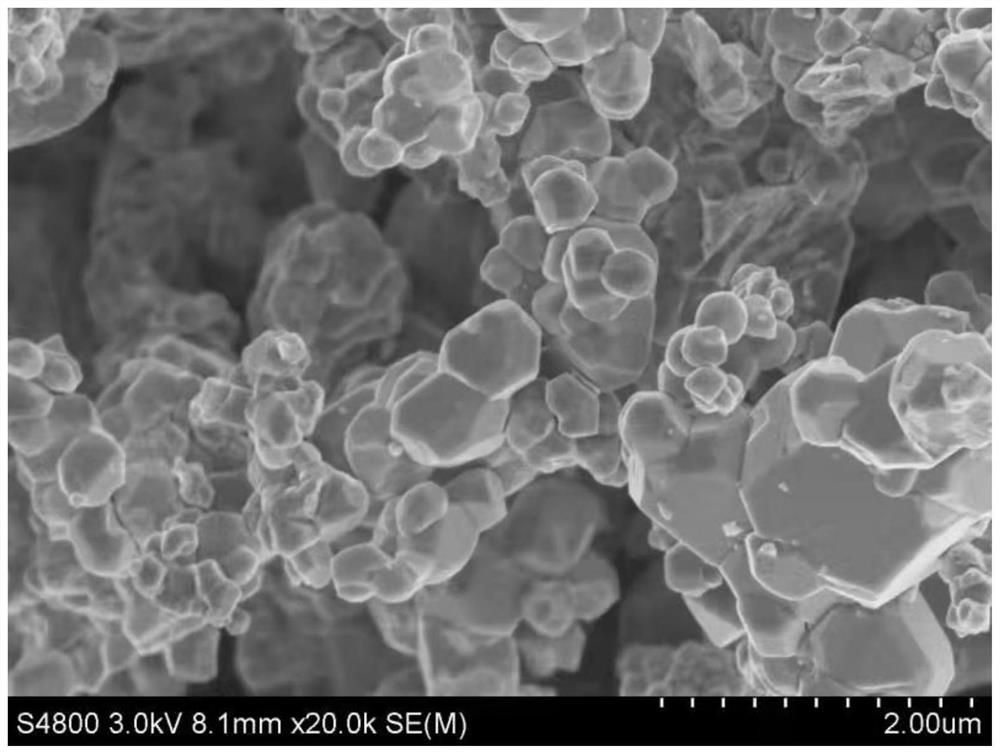

[0086] ②When the atomizing air volume is 50m 3 Under the condition of / h, the mixed solution was atomized into droplets, and calcined at a temperature of 710 °C and an oxygen mass percentage of 5.0%, and crushed to obtain Ni 0.67 Co 0.05 Mn 0.28 O ternary cathode precursor material, its crystal structure is a hexagonal layered structure, and its morphology is as attached figure 1 and 2 Electron micrographs are shown.

[0087] A LiNi 0.67 Co 0.05 Mn 0...

Embodiment 2

[0093] A spinel-type Ni 0.67 Co 0.05 Mn 0.28 O 1.02 The preparation of the ternary cathode precursor material includes the steps:

[0094] ①According to Ni 0.67 Co 0.05 Mn 0.28 O 1.02 The stoichiometric ratio of the metal elements in the chemical formula, after mixing the nickel chloride solution, the cobalt chloride solution, and the manganese chloride solution, carry out concentration treatment to obtain a mixed solution; wherein the concentrations of nickel salt, cobalt salt and manganese salt are respectively 68.2g / L, 5.1g / L, 26.7g / L.

[0095] ②When the atomizing air volume is 50m 3 Under the conditions of / h, the mixed solution was atomized into droplets, and calcined at a temperature of 740 °C and an oxygen mass percentage of 11.0%, and crushed to obtain Ni 0.67 Co 0.05 Mn 0.28 O 1.02 The ternary positive electrode precursor material has a spinel crystal structure.

[0096] A LiNi 0.67 Co 0.05 Mn 0.28 O 2 The difference between the ternary positive elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com