Surface layer reinforced type aluminum alloy plate facing foaming ceramic composite wallboard and manufacturing method of surface layer reinforced type aluminum alloy plate facing foaming ceramic composite wallboard

A technology of foamed ceramic plates and aluminum alloy plates, which is applied in building reinforcements, heat preservation, sustainable waste treatment, etc., can solve the problems of high water absorption and shrinkage, low strength, easy cracking, and poor mechanical performance, and achieve bonding Good, light weight, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples.

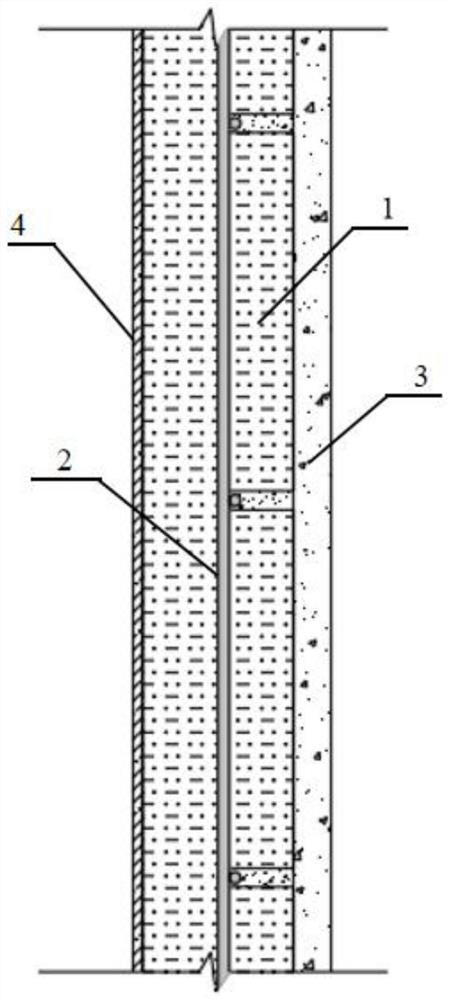

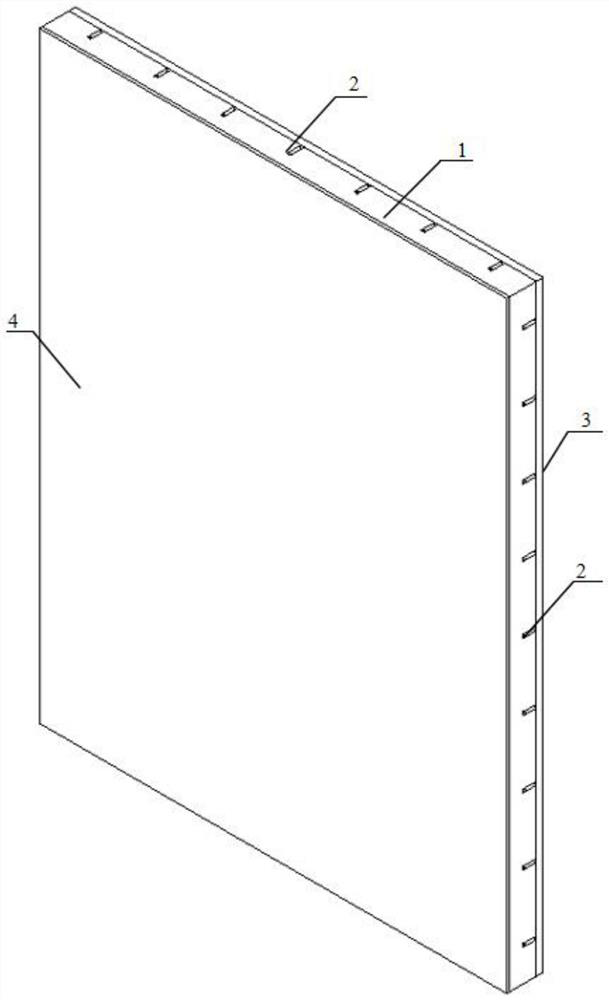

[0028] A surface layer reinforced aluminum alloy plate facing foamed ceramic composite wallboard and method thereof, the wallboard comprises a foamed ceramic board (1), a steel mesh (2), a steel mesh fiber cement mortar surface layer (3), a decorative Aluminum alloy plate (4).

[0029] According to the building area, building height and other information, "Building Structural Load Code", "Building Seismic Design Code", "Building Curtain Wall" and other specifications, the wall panel is designed.

[0030] The composite wall panel is assembled with the main structure by means of external hanging or inlay during the construction stage, and the load is transmitted through the connector; during normal use, the decorative aluminum plate on the outside of the wall panel can play an external decorative role; The surface of the inner steel mesh fiber cement mortar surface layer can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com