Liquid metal (at) rGO nano-droplet room-temperature liquid metal battery positive electrode material and preparation method thereof

A liquid metal battery and liquid metal technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor battery performance, and achieve stable cycle performance, excellent rate performance, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

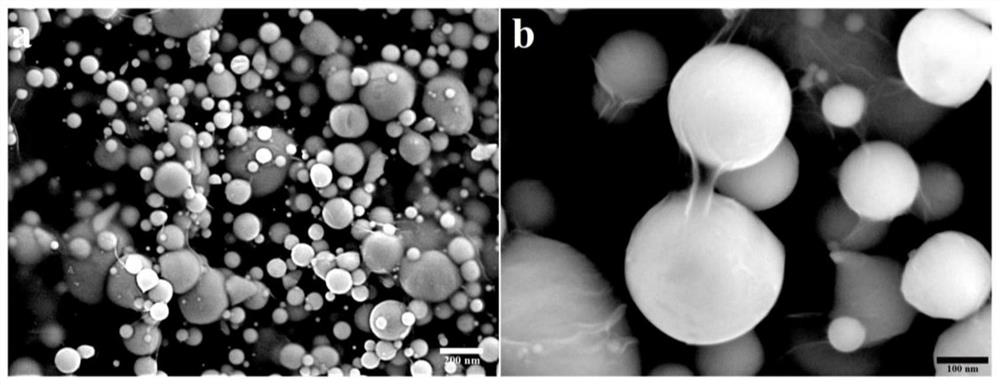

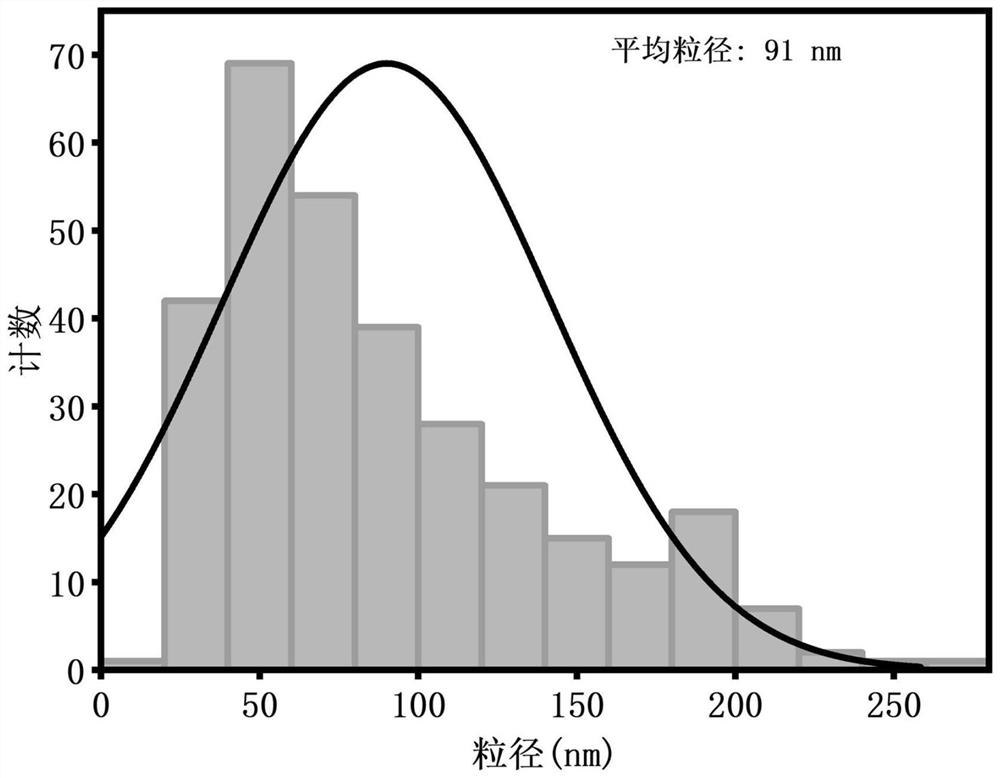

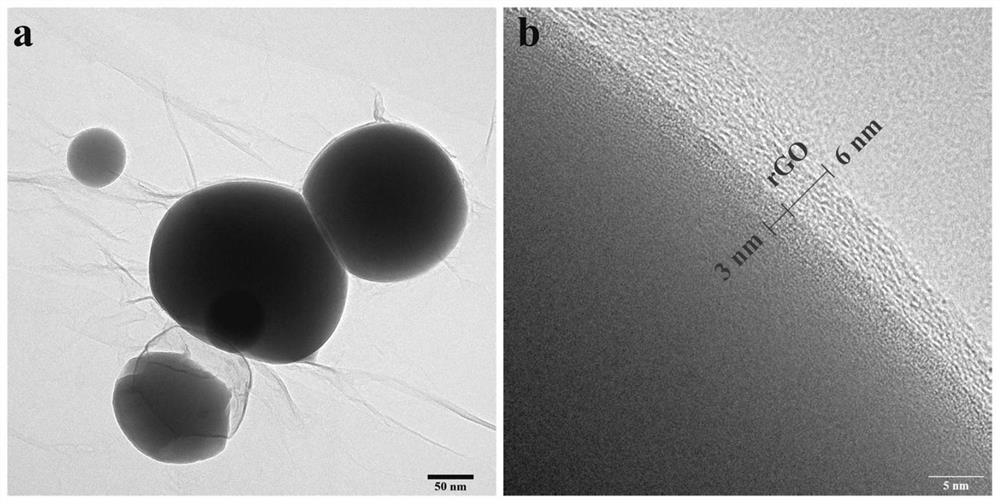

[0036] Example 1: Liquid Metal Ga 92 Sn 8 The preparation method of @rGO nanodroplet room temperature liquid metal battery cathode material, the specific steps are as follows:

[0037] (1) 3.4g of liquid metal Ga 92 Sn 8 Dispersed in 40 mL of ethanol, and ultrasonically treated with an ultrasonic probe for 1 h at room temperature to obtain liquid metal Ga 92 Sn 8 Suspension, Liquid Metal Ga 92 Sn 8 The suspension was centrifuged at a speed of 2000 rmp / min for 5 minutes, and the upper suspension was taken, and the liquid metal Ga was obtained after vacuum drying at a temperature of 40 ° C for 4 hours. 92 Sn 8 Nanodroplets;

[0038] (2) 80mg liquid metal Ga obtained in step (1) 92 Sn 8 The nanodroplets were dispersed in 1 ml of ethanol and ultrasonically treated for 30 min at room temperature to obtain liquid metal Ga 92 Sn 8 Nanosuspension;

[0039] (3) adding 8mg graphene oxide to ethanol for ultrasonic pre-dispersion for 1h, adding it to the liquid metal nano-sus...

Embodiment 2

[0046] Example 2: Liquid Metal Ga 75.5 In 24.5 The preparation method of @rGO nanodroplet room temperature liquid metal battery cathode material, the specific steps are as follows:

[0047] (1) 6.8g liquid metal Ga 75.5 In 24.5 Disperse in 53 mL of isopropanol, and ultrasonically treat it with an ultrasonic probe for 1.5 h at room temperature to obtain liquid metal Ga 75.5 In 24.5 Suspension, Liquid Metal Ga 75.5 In 24.5 The suspension was centrifuged at 3000 rmp / min for 6 min, the upper suspension was taken, and the liquid metal Ga was obtained after vacuum drying at a temperature of 40 ° C for 5 h. 75.5 In 24.5 Nanodroplets;

[0048] (2) 210mg liquid metal Ga obtained in step (1) 75.5 In 24.5 The nano-droplets were dispersed in 5 ml of isopropanol and ultrasonically treated for 35 min at room temperature to obtain liquid metal Ga 75.5 In 24.5 Nanosuspension;

[0049] (3) 10mg graphene oxide was added to 15mL isopropanol for ultrasonic pre-dispersion for 1.2h, ad...

Embodiment 3

[0053] Example 3: Preparation method of liquid metal Ga@rGO nano-droplets at room temperature liquid metal battery cathode material, the specific steps are as follows:

[0054] (1) Disperse 2.23 g of liquid metal Ga in 4.46 mL of methanol, and ultrasonically treat it with an ultrasonic probe for 2 hours at room temperature to obtain a liquid metal Ga suspension. Liquid metal Ga nano-droplets were obtained after vacuum drying at a temperature of 35 °C for 5 h;

[0055] (2) 20mg liquid metal Ga nano-droplets obtained in step (1) are dispersed in 2ml methanol, and ultrasonically treated for 40min at room temperature to obtain a liquid metal Ga nano-suspension;

[0056] (3) 1.2 mg of graphene oxide was added to 3 mL of methanol for ultrasonic pre-dispersion for 1.5 h, added to the liquid metal nanosuspension obtained in step (2), ultrasonically treated for 1.2 h at room temperature, and centrifuged at 4000 rmp / min for 5 min , take the upper suspension and dry it to obtain liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com