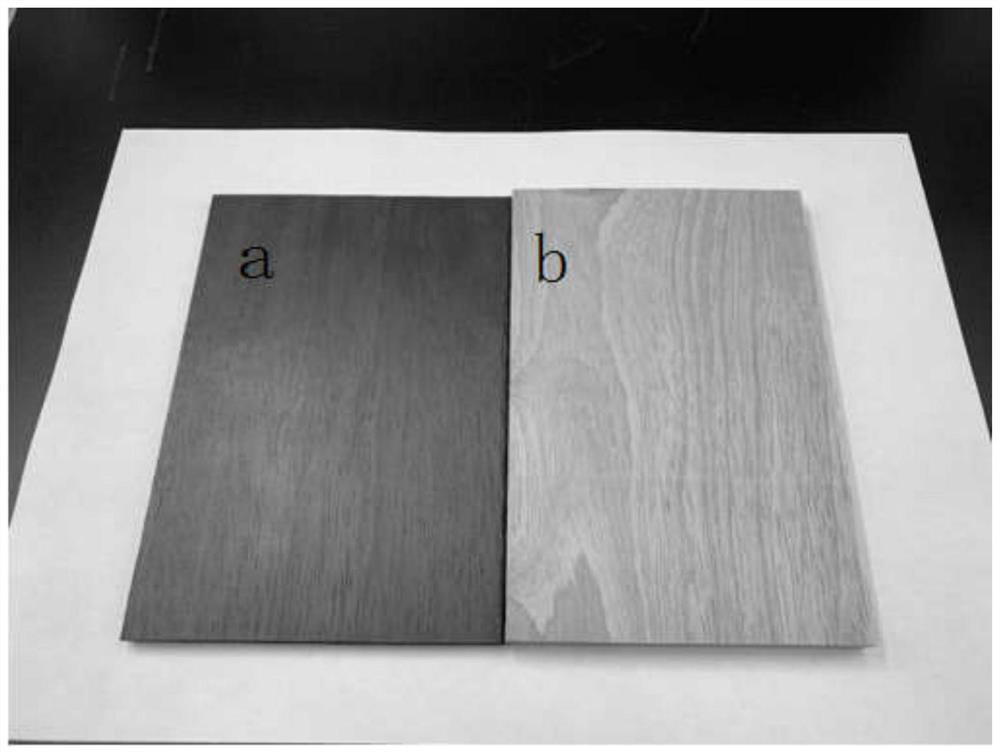

Preparation method of compressed rubber wood with stable size and mildew resistance

A dimensionally stable and rubberwood technology, applied in pressurized wood treatment, wood heating, tool manufacturing, etc., can solve the problems of easy deformation, mildew and blue stain, low density of rubber wood, etc., and achieve improved impact strength and stable dimensions Good sex and mildew resistance, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

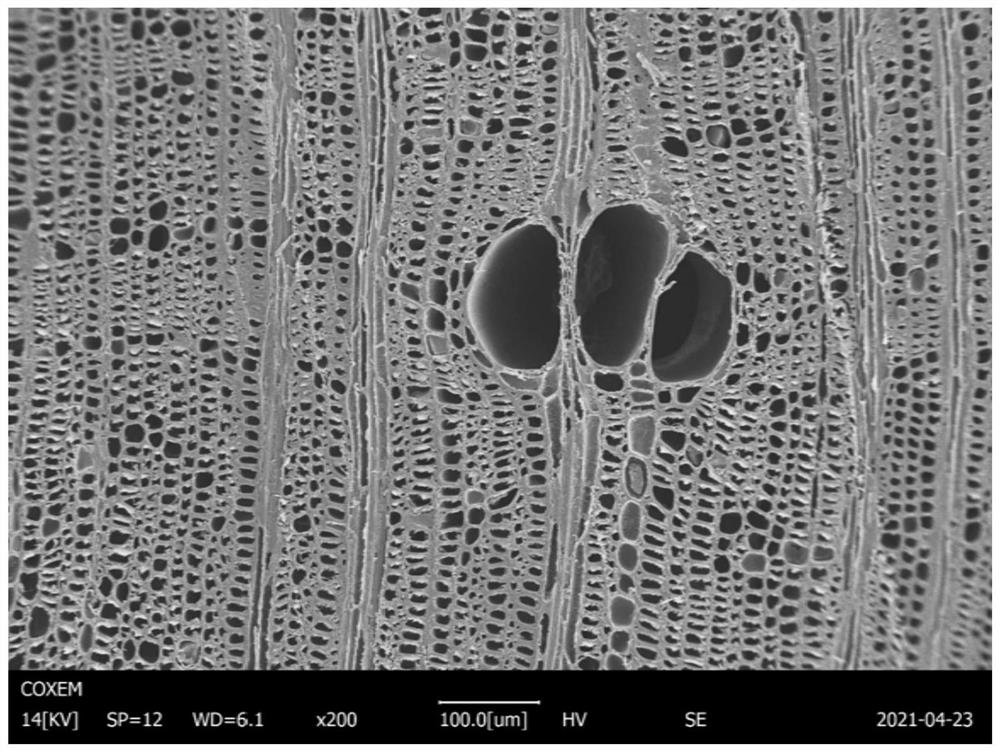

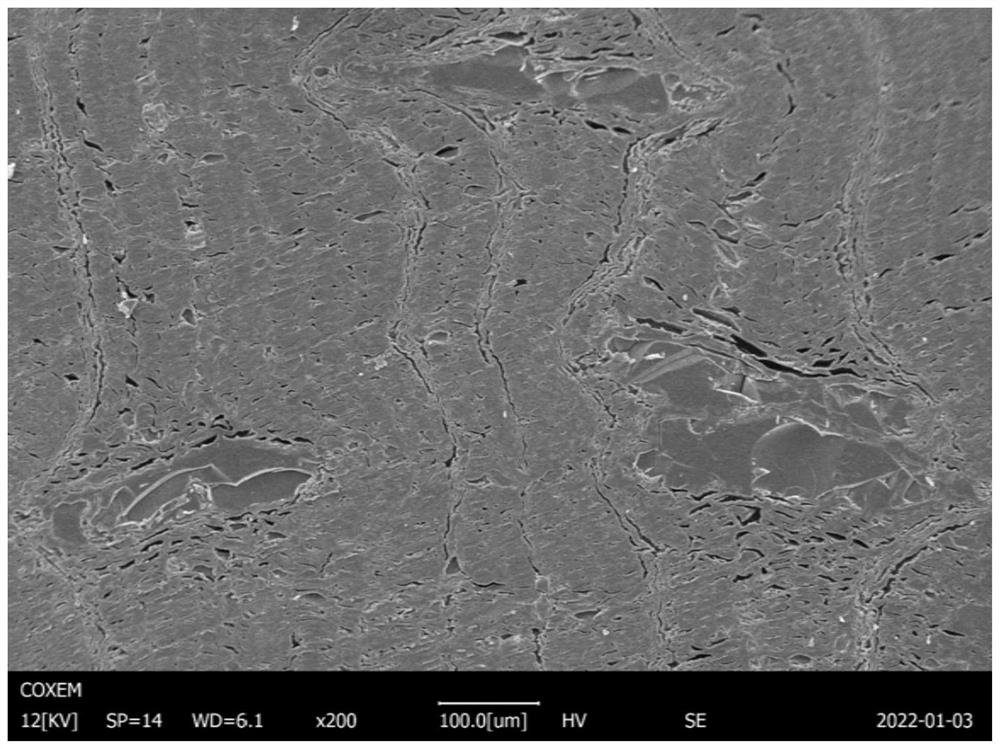

Image

Examples

specific Embodiment approach 1

[0029] Embodiment 1: The present embodiment is a preparation method of dimensionally stable and mildew-proof compressed rubber wood, which is carried out according to the following steps:

[0030] 1. Preparation of water-soluble acylated lignin solution:

[0031] The water-soluble acylated lignin is added to the water, and the pH of the solution is adjusted to the pH of rubber wood, and then an initiator and a catalyst are added to obtain a water-soluble acylated lignin solution;

[0032] The mass percentage of the water-soluble acylated lignin in the water-soluble acylated lignin solution is 5% to 15%; the mass percentage of the initiator in the water-soluble acylated lignin solution is 0.5% to 2%; The mass percentage of the catalyst in the water-soluble acylated lignin solution is 0% to 5%;

[0033] 2. Water-soluble acylated lignin solution impregnating rubber wood:

[0034] Immerse the rubber wood in the water-soluble acylated lignin solution, and then under the condition...

specific Embodiment approach 2

[0053] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the water-soluble acylated lignin described in Step 1 is prepared according to the following steps:

[0054] ①. Dissolve the dealkalized lignin in dimethyl sulfoxide, and heat it up to 80 °C, add maleic anhydride and anhydrous pyridine at a temperature of 80 °C, and then heat up to 100 °C, at a temperature of Under the condition of 100 °C, the reaction was carried out for 1 h to obtain a mixed system;

[0055] The quality of the dealkalized lignin and the volume ratio of dimethyl sulfoxide are 1g: 5mL; the mass ratio of the dealkalized lignin and maleic anhydride is 1:1.47; the dealkalized lignin The volume ratio of the mass and anhydrous pyridine is 1g: 2.41mL;

[0056] 2. Disperse the mixed system in a poor solvent, precipitate and centrifuge to remove the supernatant to obtain the bottom product;

[0057] 3. Dissolving the bottom product in dimethyl sulfoxide to obtain a bottom product so...

specific Embodiment approach 3

[0058] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the poor solvent described in step ② is ethyl acetate or ethanol. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com