Photosensitive diamine monomer and preparation method thereof, resin containing photosensitive diamine monomer, and photosensitive resin composition

A technology of photosensitive resin and diamine monomer, applied in the field of photosensitive resin composition, can solve the problems of increased solubility difference, low film retention rate of cured film, large acting force, etc., and achieves improved transparency and high photosensitivity. , the effect of enhancing photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

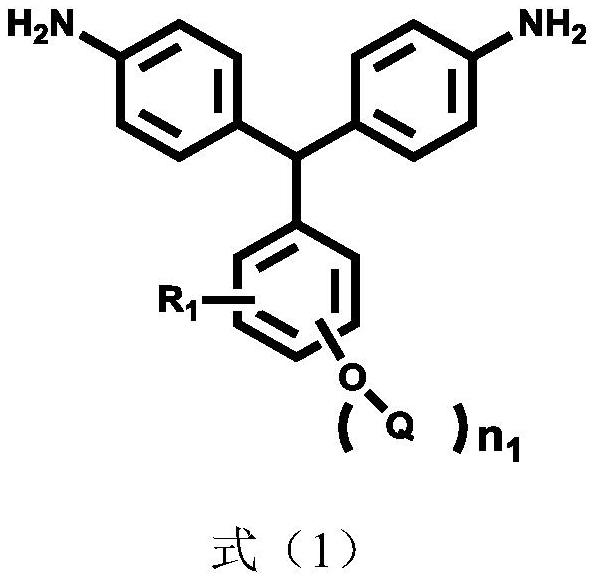

Method used

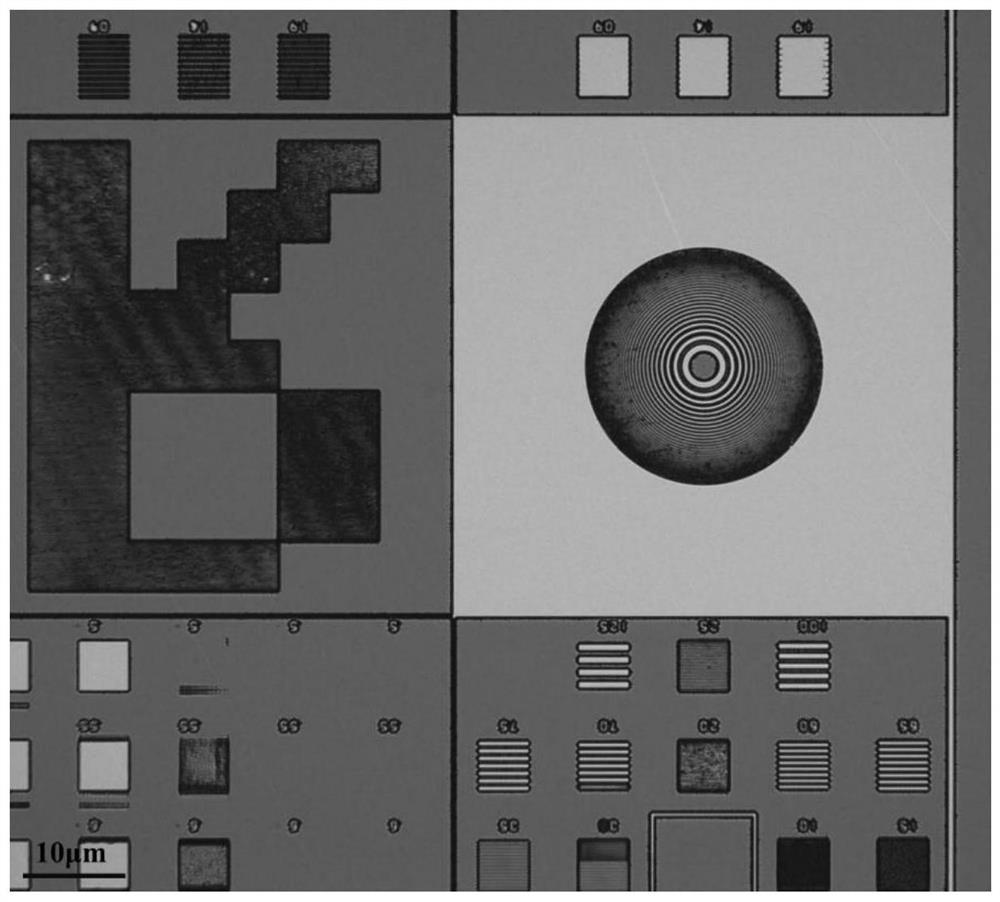

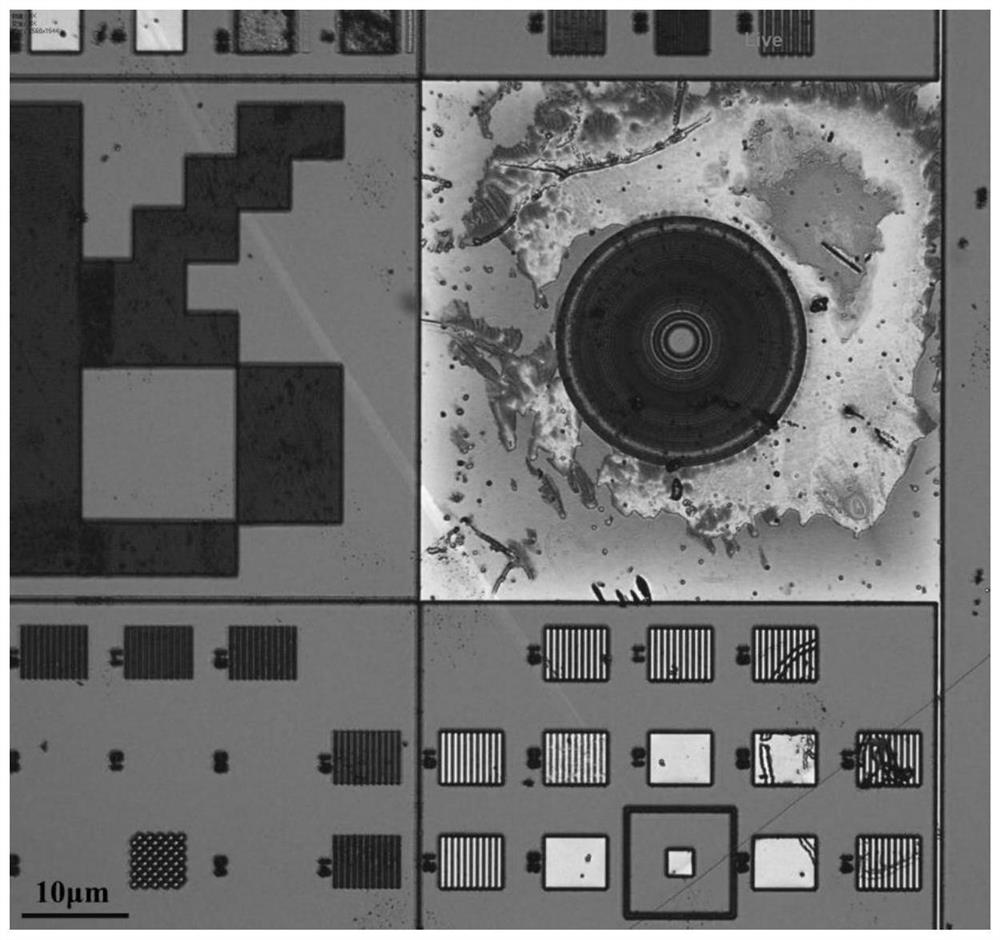

Image

Examples

preparation example Construction

[0115] The preparation method of the above-mentioned photosensitive diamine monomer specifically comprises the following steps:

[0116] (1) Preparation of primary product: mix and fully dissolve hydroxybenzaldehyde, triethylamine and DMAC to obtain a reaction solution; control the system temperature of the reaction solution to be (-10)-(-5) °C, add the reaction solution The mixed solution of diazonaphtholsulfonyl chloride and DMAC was dropped, and the reaction was stirred to obtain the primary product.

[0117] Wherein, the hydroxy-containing benzaldehyde is selected from p-hydroxybenzaldehyde, 3,4-dihydroxybenzaldehyde, 4-hydroxy-3-trifluoromethylbenzaldehyde, 4-hydroxy-3-trifluoromethoxybenzaldehyde , 4-hydroxy-3-methylbenzaldehyde, 5-methyl-3-(2-benzothiazolyl)-2-hydroxybenzaldehyde, 3-hydroxy-4-benzyloxybenzaldehyde and 3-(tri Fluoromethoxy) o-hydroxybenzaldehyde.

[0118] (2) Preparation of secondary product: fully react the primary product obtained in step (1) with hy...

preparation example 1-6

[0132] Preparation Examples 1-6 respectively provide a photosensitive diamine monomer. The difference is that the types of hydroxy-containing benzaldehyde and diazonaphthol sulfonyl chloride used in the preparation method of each photosensitive diamine monomer are different.

[0133] The preparation process of the above-mentioned photosensitive diamine monomer is shown in Table 1, and its preparation method specifically includes the following steps:

[0134] (1) Preparation of primary product: mix hydroxybenzaldehyde, triethylamine and DMAC in a three-necked flask, stir to fully dissolve the three, and obtain a reaction solution; reduce the system temperature of the reaction solution to -5°C, and add to the reaction The mixed solution of diazonaphtholsulfonyl chloride and DMAC is dropped into the solution, and the reaction is stirred to obtain the primary product.

[0135] (2) Preparation of secondary product: add hydrochloric acid dropwise to the primary product obtained in ...

preparation example 7-16

[0158] Preparation Examples 7-16 respectively provide a resin containing a photosensitive diamine monomer. The difference lies in: in the preparation process of each resin containing photosensitive diamine monomer, the photosensitive diamine monomer used is shown in Table 3 in detail. Among them, the types of photosensitive diamine monomers respectively represent the photosensitive diamine monomers prepared by the corresponding preparation examples in the above-mentioned preparation examples 1-6.

[0159] The preparation method of the above-mentioned resin containing photosensitive diamine monomer specifically comprises the following steps:

[0160] (1) preparation of dianhydride solution: under nitrogen flow, in the 500ml there-necked flask equipped with agitator, dropping funnel and thermometer, successively add 4,4'-oxydiphthalic anhydride (ODPA), N-methane pyrrolidone (NMP), stirring at room temperature to fully dissolve each substance to obtain a dianhydride solution;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com