Antimony-based integrated electrode and preparation method and application thereof

An electrode, antimony-based technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low battery energy density, cumbersome preparation method of antimony-based integrated electrodes, etc., to improve energy density, reduce shedding, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of an antimony-based integrated electrode, comprising:

[0030]Step 1: cleaning the titanium foil to be deposited, and then vacuum drying; the cleaning treatment is preferably ultrasonic cleaning of the titanium foil to be deposited with acetone, ethanol and deionized water; the vacuum drying temperature The temperature is preferably 60° C., and the time is preferably 20 minutes; the thickness of the titanium foil is preferably 10-30 μm.

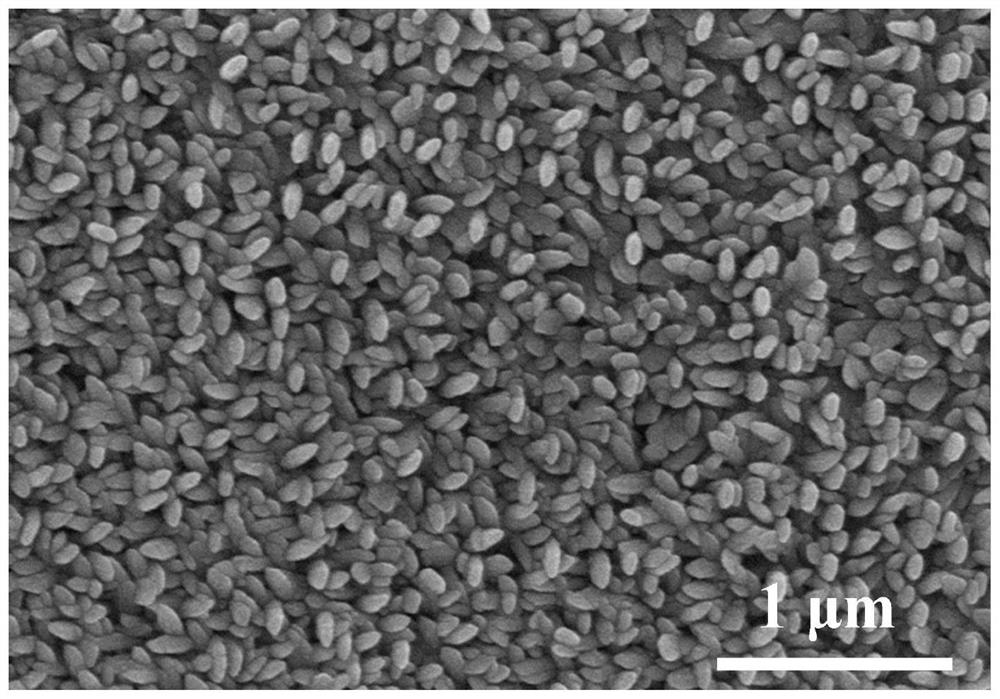

[0031] Step 2: SbF in the reactor 3 Aqueous solution, put the titanium foil obtained in step 1 vertically in the reactor, then place the twisted reactor in an oven, heat the oven to 140-200°C and keep it for 8-16h, preferably at 180°C for 12h, to obtain The surface of the titanium foil has deposited layers, followed by in-situ deposited Sb 3+ Sb 5+ o 4 layer and in situ coated Ti(OH) 4 layer; the SbF 3 The mass fraction of the aqueous solution is preferably 0.33-0.50%, more preferably ...

Embodiment 1

[0042] Step 1: The surface of the titanium foil (30mm×45mm) to be deposited is ultrasonically cleaned with acetone, ethanol and deionized water, and dried in a vacuum drying oven for 20 minutes;

[0043] Step 2: Prepare SbF with a mass fraction of 0.33% in a 50mL reactor 3 Aqueous solution, put the titanium foil obtained in step 1 vertically in the reactor, then place the twisted reactor in an oven, heat the oven to 180°C and keep it for 12h, the titanium foil obtained has a deposited layer on the surface, followed by the original bit-deposited Sb 3+ Sb 5+ o 4 layer and in situ coated Ti(OH) 4 layer, the deposition method is chemical deposition;

[0044] Step 3: Fix the titanium foil obtained in step 2, specifically: place the titanium foil in the constant temperature zone of the tube furnace, and then seal the tube furnace; then vacuumize the tube furnace first, and then Introduce argon, then evacuate, and then inflow argon until repeating the operation three times, then...

Embodiment 2

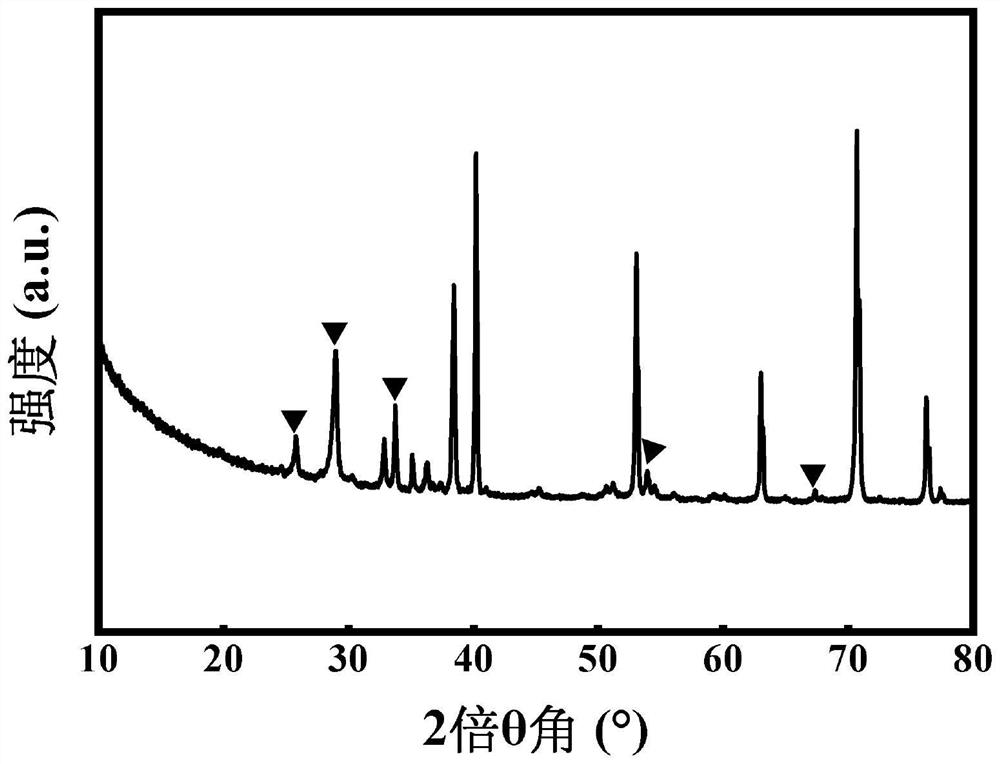

[0049] The steps of this embodiment are the same as in Embodiment 1, the difference is that SbF 3 The mass fraction of the aqueous solution is 0.41%; figure 2 As shown, the XRD analysis results confirmed the presence of Sb in the obtained samples 3+ Sb 5+ o 4 Mutually.

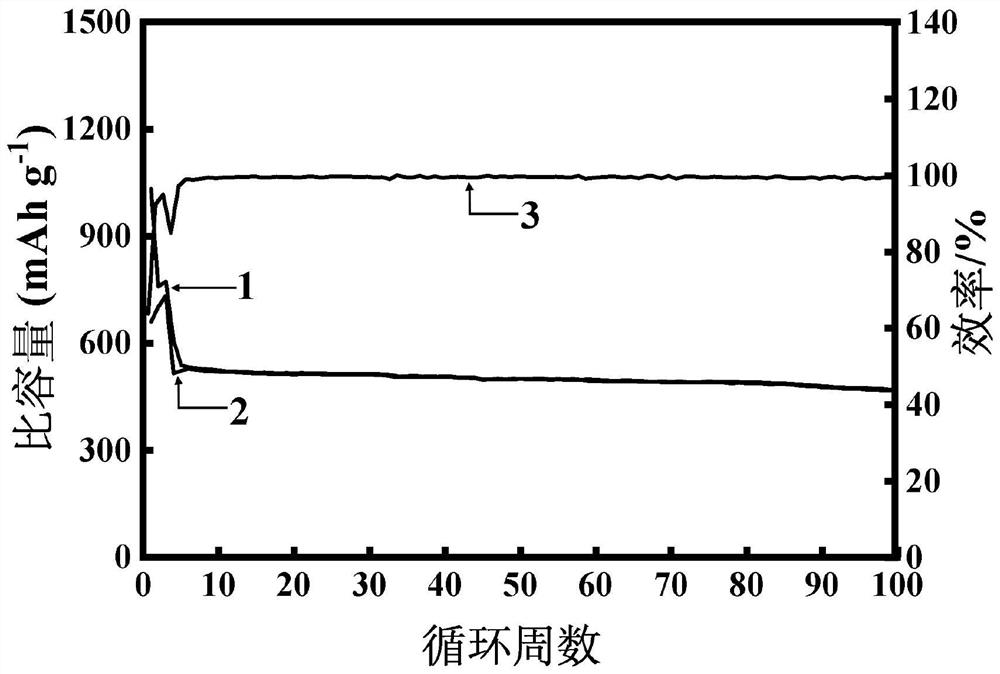

[0050] like Figure 4 shown, at 0.5A g -1 316.1mAh g can still be released after 50 cycles at the highest current density -1 The specific capacity, its first coulombic efficiency is 66.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com