Electrode additive, preparation method thereof and positive plate

An additive and electrode technology, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems affecting battery cycle performance and rate performance, low conductivity of positive electrode, etc., achieve excellent electron transfer efficiency, increase transfer rate, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

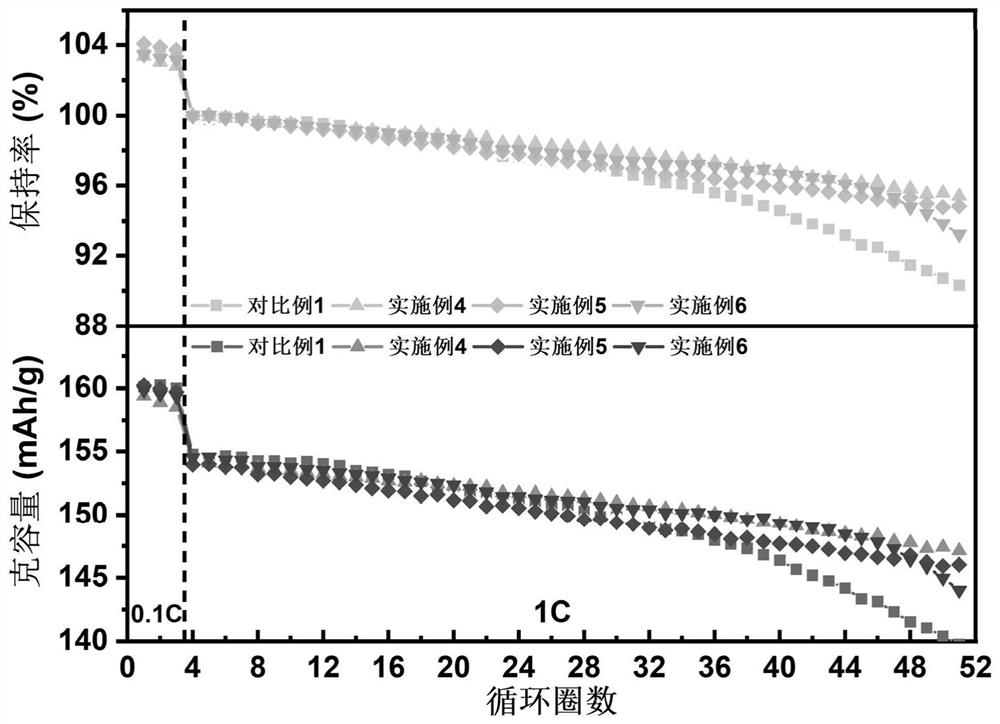

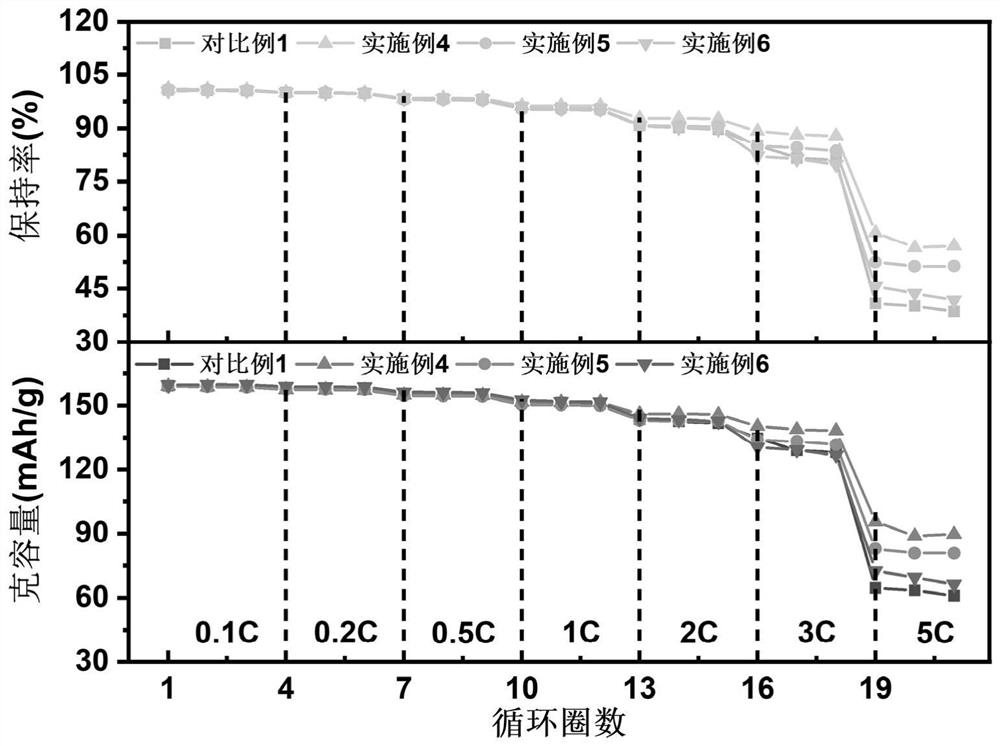

Examples

preparation example Construction

[0025] A first aspect of the embodiments of the present application provides a method for preparing an electrode additive, comprising the following steps:

[0026] S10. After mixing the titanium source, aluminum source, phosphate, lithium source, acidic complexing agent, lye and alcohol solvent to form a sol, drying to obtain a titanium aluminum lithium phosphate precursor;

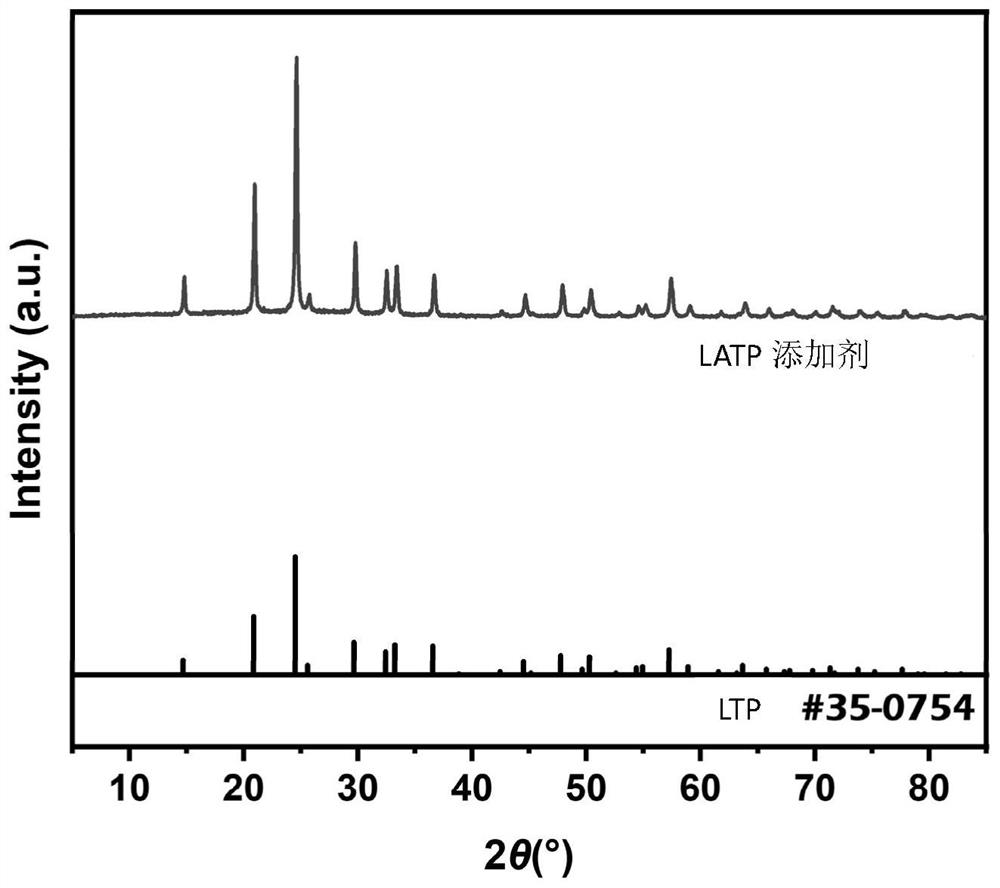

[0027] S20. After the first sintering treatment is performed on the titanium aluminum lithium phosphate precursor under an inert atmosphere, the second sintering treatment is performed in a mixed atmosphere containing oxygen to obtain an electrode additive; the electrode additive includes a porous titanium aluminum lithium phosphate inner core, The carbon material filled in the pores of the lithium titanium aluminum phosphate core, and the carbon shell layer coated on the outer surface of the lithium titanium aluminum phosphate core.

[0028] In the preparation method of the electrode additive provided in...

Embodiment 1

[0060] An electrode additive, the preparation of which comprises the steps:

[0061] ①According to Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 The stoichiometric ratio of aluminum nitrate, lithium nitrate and ammonium dihydrogen phosphate was weighed, and the total metal cation (Li + , Al 3+ , Ti 4+ ) citric acid with a molar ratio of 2:1, completely soluble in water. To the solution, add tetrabutyl titanate in a stoichiometric ratio, and stir for 3h until it is completely uniform. Add ammonia water dropwise to the solution to adjust pH to 5, then add ethylene glycol with a molar ratio of 1:1 to citric acid, stir and mix evenly. The gel was aged by rotary evaporation at 80°C for 10 h, and then the solvent was evaporated in a drying oven at 100°C to form a dry gel.

[0062] ②Crush the xerogel into powder and then sinter it in a tube furnace, protected by an argon atmosphere, with a flow rate of 200mL / min, heated to 550°C for 1 h at 5°C / min, and then continued to heat up to 850°C at...

Embodiment 2

[0064] An electrode additive, the preparation of which comprises the steps:

[0065] ①According to Li 1.4 Al 0.4 Ti 1.6 (PO 4 ) 3 The stoichiometric ratio of aluminum nitrate, lithium nitrate and ammonium dihydrogen phosphate was weighed, and the total metal cation (Li + , Al 3+ , Ti 4+ ) citric acid with a molar ratio of 2:1, completely soluble in water. To the solution, add tetrabutyl titanate in a stoichiometric ratio, and stir for 3h until it is completely uniform. Add ammonia water dropwise to the solution to adjust pH to 5, then add ethylene glycol with a molar ratio of 1:1 to citric acid, stir and mix evenly. The gel was aged by rotary evaporation at 80°C for 10 h, and then the solvent was evaporated in a drying oven at 100°C to form a dry gel.

[0066] ②Crush the xerogel into powder and then sinter it in a tube furnace, protected by an argon atmosphere, with a flow rate of 200mL / min, heated to 550°C for 1 h at 5°C / min, and then continued to heat up to 850°C at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com