Sulfate-erosion-resistant concrete admixture, preparation method thereof and concrete

A concrete admixture and sulfate-resistant technology, applied in the direction of hydrotalcite and other directions, can solve the problems of reducing the mechanical properties of concrete, complicated preparation process of the admixture, affecting the promotion and application of products, etc. Small, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The sulfate-resistant concrete admixture provided in this example contains the following components by mass: 100 parts of barium carbonate, 100 parts of barium hydroxide, 80 parts of hydrotalcite, 50 parts of fly ash, and 50 parts of mineral powder.

[0020] The preparation method of the sulfate-resistant concrete admixture provided in this embodiment includes: preparing hydrotalcite, and mixing barium carbonate, barium hydroxide, hydrotalcite, fly ash and mineral powder in prescribed amounts; the preparation method of the hydrotalcite includes mixing Magnesium nitrate, aluminum nitrate, sodium carbonate, sodium hydroxide and water are mixed in a mass ratio of 21:7:1:6:180 to prepare a mixed alkali solution, the pH of the solution is controlled to be 9, and after crystallization at a constant temperature for 24 hours, suction filtration, drying and grinding , calcined at 450°C for 200min.

Embodiment 2

[0022] The sulfate-resistant concrete admixture provided in this example adopts the same preparation method as in Example 1, except that the following components are used in parts by mass: 100 parts of barium carbonate, 100 parts of barium hydroxide, 80 parts of hydrotalcite, powder 60 parts of coal ash and 60 parts of mineral powder.

experiment example 1

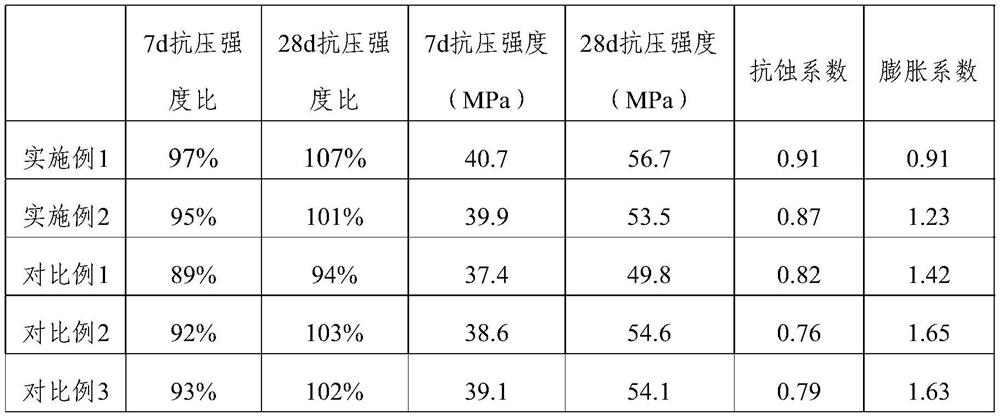

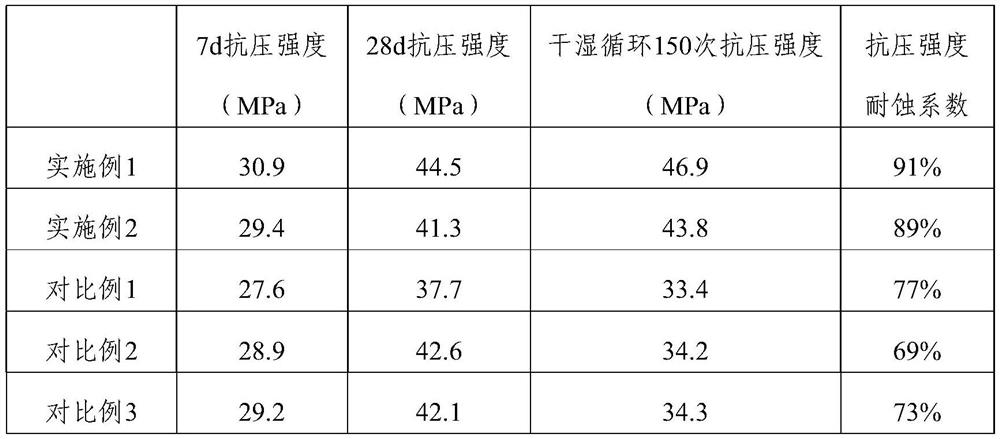

[0030] The performance tests of the sulfate-resistant concrete admixtures in Examples 1-2 and Comparative Examples 1-3 were carried out. With reference to "Anti-sulfuric acid corrosion preservatives for concrete" (JC / T 1011-2006), the cement in the mortar is Portland benchmark cement, the sand is standard sand, and the water is tap water. During the test, the amount of sulfate-resistant concrete admixtures accounted for 12% of the cement, the performance test results of its mortar are shown in Table 1.

[0031] Table 1 Test results of performance of anti-sulfate corrosion concrete admixtures

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com