Anti-ultraviolet fireproof wood-plastic composite material and preparation thereof

A wood-plastic composite material, anti-ultraviolet technology, applied in the direction of plant fiber, fiber treatment, textile and paper making, etc. Cracking, improving mechanical strength and mechanical properties, high resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

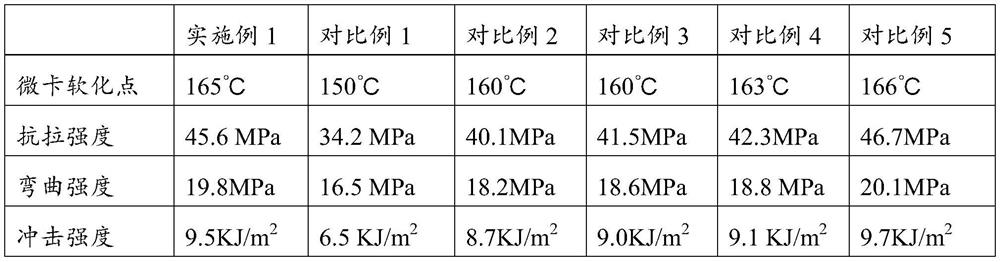

Examples

Embodiment 1

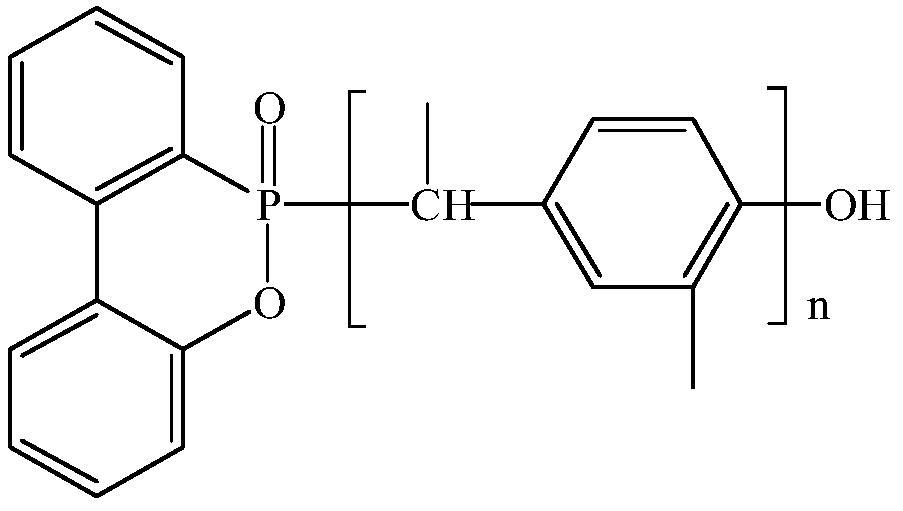

[0029] An anti-ultraviolet fire-resistant wood-plastic composite material mainly includes the following components and their parts by weight: polyethylene 80, carboxymethyl chitosan modified plant fiber 60, phosphorus-containing phenolic resin 5, P-N-Si flame retardant 2, Nano titanium ceramic resin 2, bamboo charcoal powder 20, titanium oxide / o-hydroxybenzophenone / phthalocyanine blue mixture 3, calcined diatomaceous earth 5, maleic anhydride grafted polyethylene 10, antioxidant 1.

[0030] The preparation method of the above-mentioned anti-ultraviolet fireproof wood-plastic composite material mainly comprises the following steps:

[0031] (1) Mix and stir thermoplastic plastic, carboxymethyl chitosan modified plant fiber, phosphorus-containing phenolic resin, calcined diatomite, and bamboo charcoal powder for 3-5 hours;

[0032] (2) Add P-N-Si flame retardant, nano-titanium ceramic resin, titanium oxide / o-hydroxybenzophenone / phthalocyanine blue mixture, antioxidant; stir for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com