Gel-cotton composite material for cooling clothes suitable for tunnel construction and preparation method of gel-cotton composite material

A technology for tunnel construction and composite materials, applied in plant fibers, fiber processing, textiles and papermaking, etc., can solve the problems of solution exudation, environmental pollution, uneven dispersion of gel for cooling clothing, etc., to reduce discomfort and low prices. , the effect of reducing the probability of discomfort symptoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Using the preparation method of the present invention, in the system, the polysilicon network can be connected with the polymer network through entanglement and intermolecular hydrogen bonds (carboxyl group-water molecule-silicic acid). Finally, an inorganic / organic double network interpenetrating network gel system was formed, which enhanced the strength, elasticity and water retention of the high toughness P(AA-co-AM) / WG gel system.

[0041] Step 9, drying the polymer-dispersed cotton in the step 8 to obtain a gel-cotton composite material for cooling clothing.

specific Embodiment

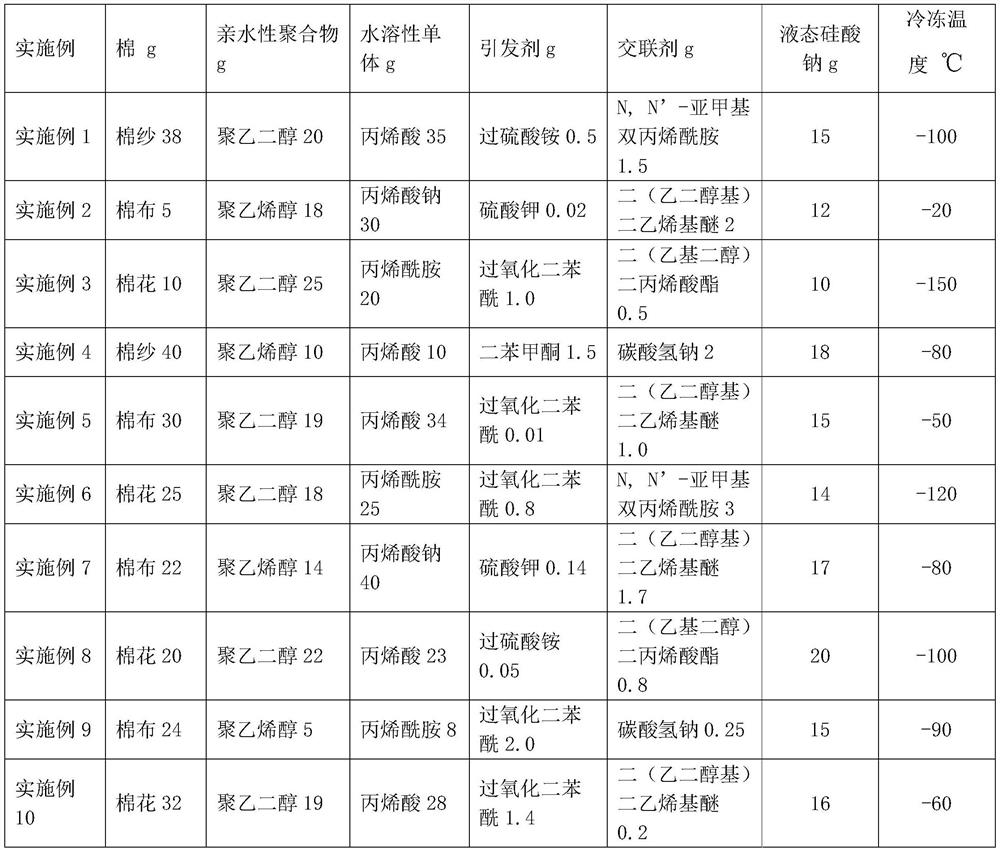

[0043]

[0044]The gel-cotton composite materials prepared in each example are made into clothes, and the construction workers put the cotton on the body through thin clothes. Because cotton is used as the base material, it is lighter and more comfortable. The prepared gel has the effect of absorbing sweat and keeping it in the cotton.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com