Method for repairing acidification system of anaerobic reactor under condition of high influent COD (Chemical Oxygen Demand) concentration

An anaerobic reactor and anaerobic acidification technology, which is applied in the field of repairing anaerobic reactor acidification system under the condition of high influent COD concentration, can solve problems such as failure to repair, cell membrane death, etc., achieve simple operation and promote the formation of acetate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

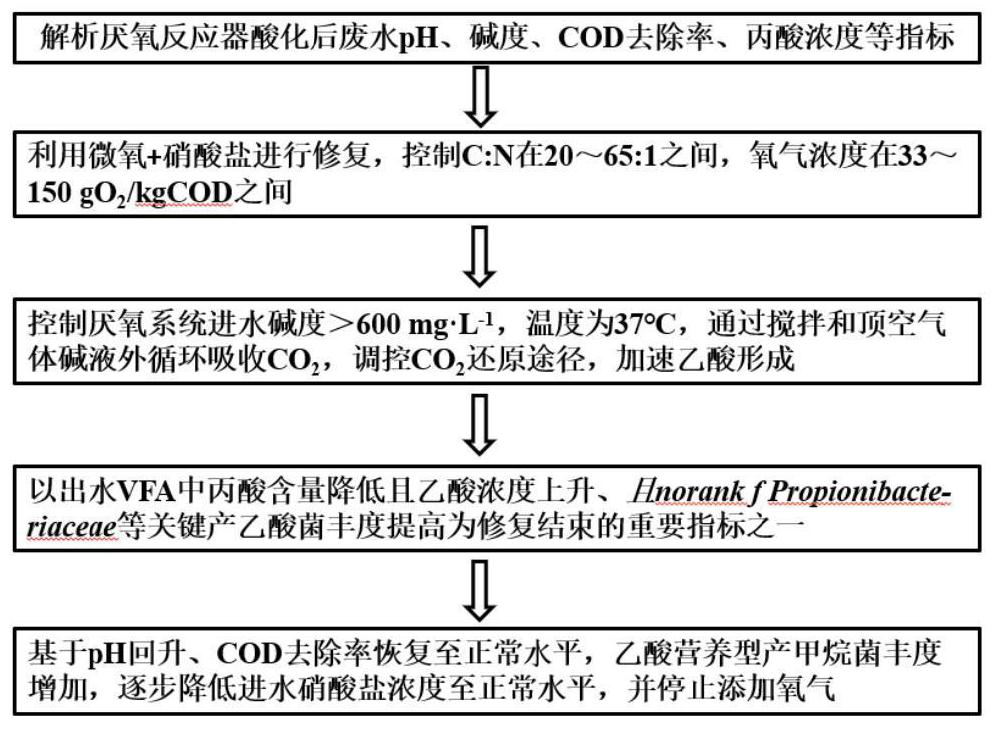

[0044] The effects of the method for restoring methane production after acidification of the anaerobic bioreactor under different influent COD concentration conditions provided in the embodiments of the present invention are as follows: figure 1 It includes the following processing steps:

[0045] Step S1, analysis of system characteristics after acidification of anaerobic reactor

[0046] Analyze the water quality after acidification of the anaerobic wastewater treatment system, pH = 5.5, COD removal rate ≤ 60% (the original influent COD concentration of the acidification reactor> 8000mg / L);

[0047] Step S2, influent water quality control: control the initial influent COD concentration to 2000 mg / L, and then gradually increase it to 6000 mg / L.

[0048] Step S3, adding exogenous nitrate and oxygen

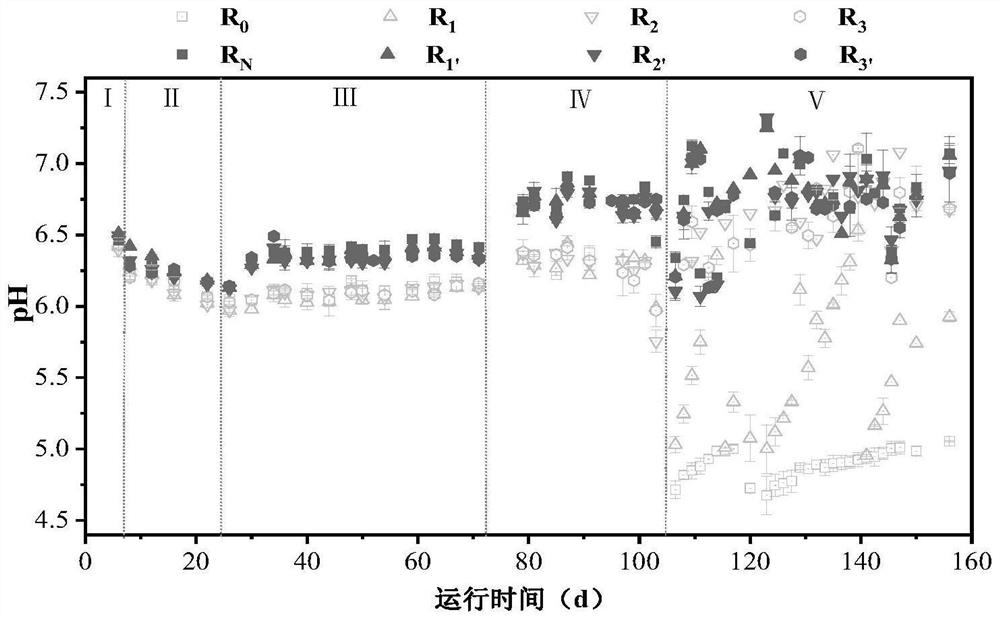

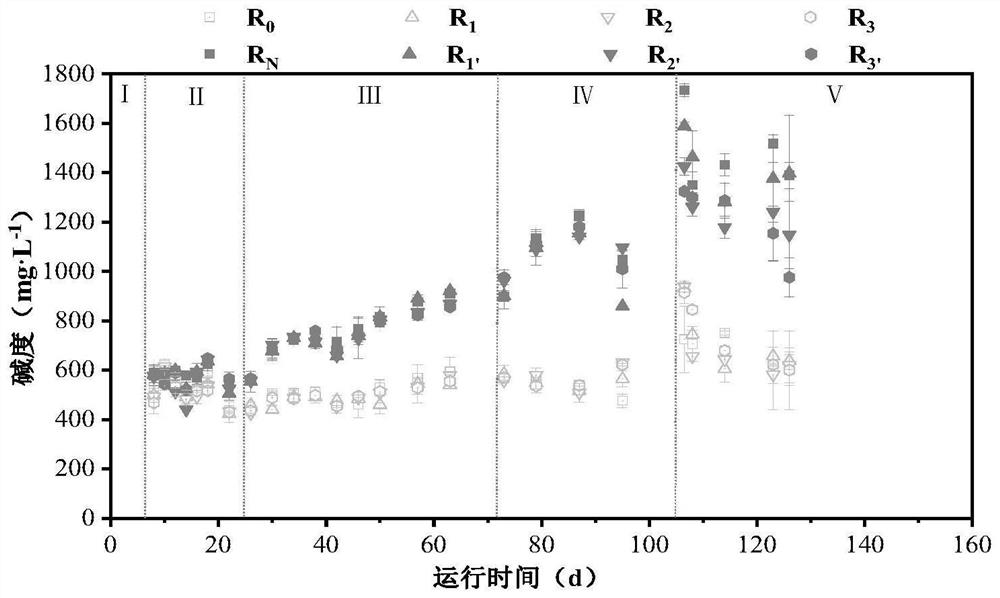

[0049] Specifically, designed to add exogenous nitrates and O 2 Concentration, a total of 8 experimental groups were set up, C:N was 22-33:1, and the amount of oxygen introduce...

Embodiment 2

[0083] The recovery control method after acidification of the anaerobic bioreactor under the condition of high influent COD concentration provided by the embodiment of the present invention includes the following processes:

[0084] Step S1, analysis of system characteristics after acidification of anaerobic reactor

[0085]Analysis of the water quality after acidification of the anaerobic wastewater treatment system, the COD concentration of the influent water is >8000mg / L, pH=4.5, the COD removal rate is ≤60%, and the propionate content is 533mg / L, accounting for 19% of the total VFA;

[0086] Step S2, influent water quality control: control the influent COD concentrations to be 6000 and 8000 mg / L, respectively.

[0087] Step S3, adding exogenous nitrate and oxygen

[0088] Specifically, designed to add exogenous nitrates and O 2 Concentration, control 2 groups of high influent COD concentration: the experimental group R6000-H with the influent COD concentration of 6000mg / ...

Embodiment 3

[0120] The recovery control method of the UASB reactor after acidification provided by the embodiment of the present invention comprises the following process:

[0121] Analysis of the water quality after acidification of the anaerobic wastewater treatment system shows that the COD concentration of the influent water is >8000 mg / L, pH=5.3, and the COD removal rate is ≤50%; the initial influent COD concentration is controlled to be 3000 and 6000 mg / L, respectively. For the two groups of UASB reactors, the initial influent COD concentrations were set to 3000 (RL) and 6000 mg / L (RH), respectively, and the HRT was 2d. Among them, the concentration of nitrate added in RL is 80mg / L, and the amount of oxygen added in a single cycle is 30mgO 2 / gCOD; the concentration of nitrate added in RH is 80mg / L, and nitrate is added twice in a single cycle, and the amount of oxygen added is also 30mgO 2 / gCOD. The repair culture was carried out to the second stage (59-80 d), the addition of ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com