Coking wastewater treatment device and method

A coking wastewater and pretreatment technology, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve problems such as low film, high wastewater recovery rate, fouling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

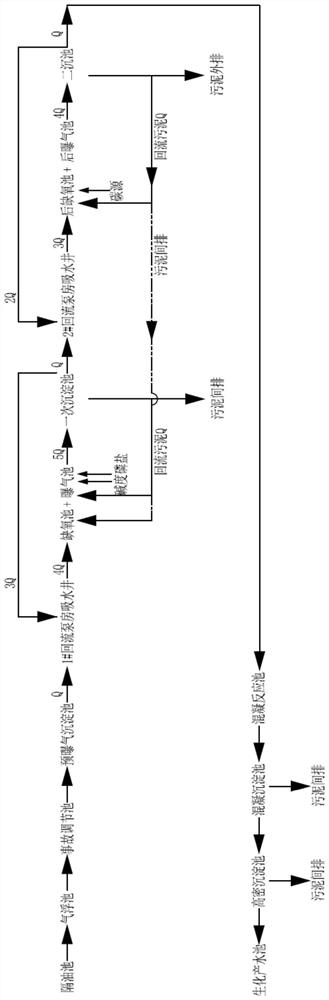

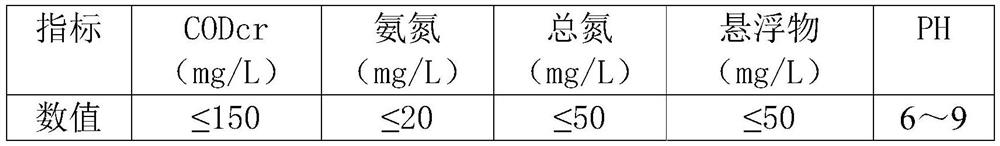

[0023] Embodiments 1 to 3 are based on figure 1 In the process flow chart of the treatment process, the coking wastewater is treated, and the influent volume of the coking wastewater is 100m 3 / h (60m of phenol-cyanide wastewater 3 / h, domestic sewage, shaft seal cooling water, gas pipeline condensate water, initial rainwater totaling 40m 3 / h), the main indicators of influent water are COD≤4500mg / L, ammonia nitrogen≤200mg / L, pH value 6~9, volatile phenols≤1000mg / L, petroleum ≤50mg / L.

[0024] The process operation flow is carried out according to the process steps and flow chart in the content of the invention:

[0025] (1) The coking wastewater pretreatment system is divided into two series, the wastewater first enters the grease trap, and the HRT is 2.5h;

[0026] (2) the coking wastewater after the oil separator treatment in step (1) flows into the flotation tank by gravity, and the HRT is 40min;

[0027] (3) the effluent from the air flotation tank flows into the regu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com