Continuous polymerization devolatilization method and device for polylactic acid

A devolatilization device, polylactic acid technology, applied in separation methods, chemical instruments and methods, evaporation, etc., can solve the problems of uneven heating of materials, difficulty in further increasing the molecular weight of products, and wide residence time distribution. The effect of uniform distribution of components, avoiding large fluctuations in liquid level, and stable liquid level control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

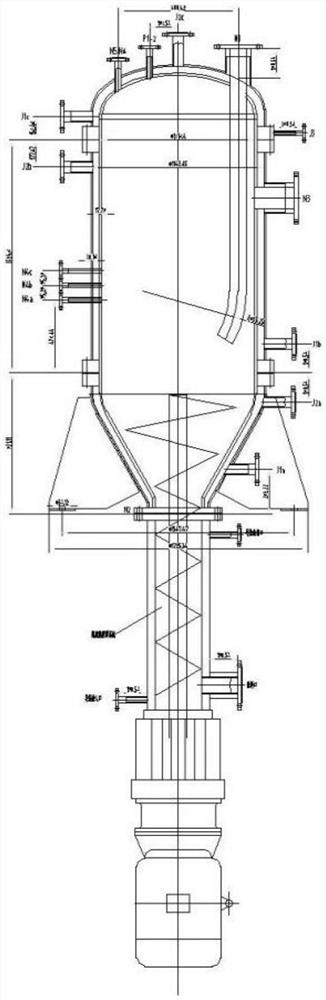

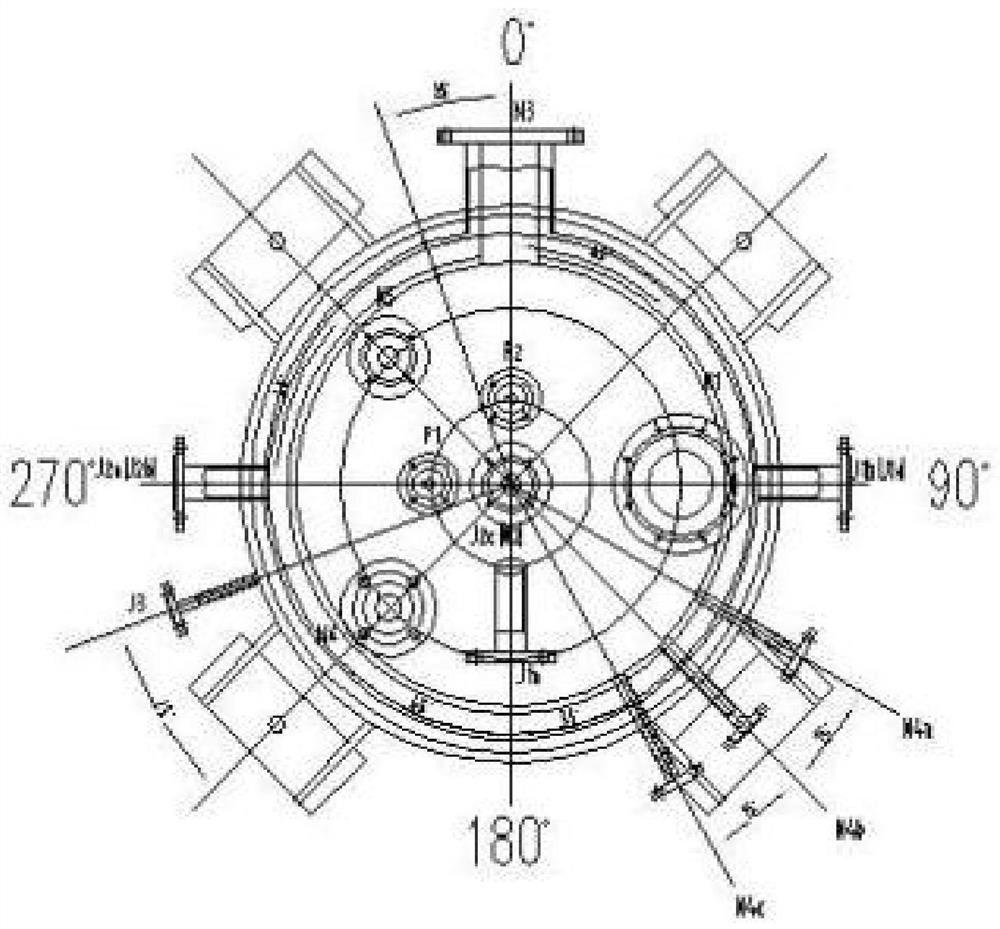

[0034] like figure 1 , 2 As shown, a method and device for continuous polymerization and devolatilization of polylactic acid described in this embodiment, the method comprises the following steps:

[0035] Step 1, the polylactic acid melt from the lactide polymerization system first enters the falling film evaporation heater on the upper part of the vertically arranged devolatilization reaction device to heat the melt;

[0036] Step 2, the low-boiling substance and the lactide gas produced in the devolatilization reaction process become the lactide liquid and return to the lactide buffer tank after passing through the condensing device;

[0037] Step 3, non-condensable gas and low boilers are sucked into the vacuum buffer tank for further condensation and crystallization, and are discharged to the sewage system under the action of spray water;

[0038] Step 4, the polymer melt after devolatilization is extruded by the devolatilizer screw to the inlet of the devolatilization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com