Preparation method of methylamine acetate ionic liquid

A technology of ionic liquid and methylamine acetate, which is applied in the field of preparation of methylamine acetate ionic liquid, can solve the problems of easy gasification of methylamine and low yield of methylamine acetate ionic liquid, and achieve avoidance of by-products, stable temperature and stable reaction fast speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The embodiment of the present invention provides a preparation method of methylamine acetate ionic liquid, and the preparation method comprises the following steps:

[0033] Step 1. Under the stirring condition of the rotating speed of 200rpm, acetic acid is added dropwise to the methylamine aqueous solution with a concentration of 20wt% at a speed of 0.6mL / min, and the temperature is 8°C, the power is 150W, and the microwave condition is 2450MHz The batch reaction is carried out 6 times to obtain an ionic liquid mixture. The conditions of the batch reaction are as follows: the microwave irradiation time is 2 min, the first intermittent time is 2.5 min, and the n+1 intermittent time is longer than the nth intermittent time by 30s , 1≤n≤5; the molar ratio of the above formic acid and methylamine is 1:1.1;

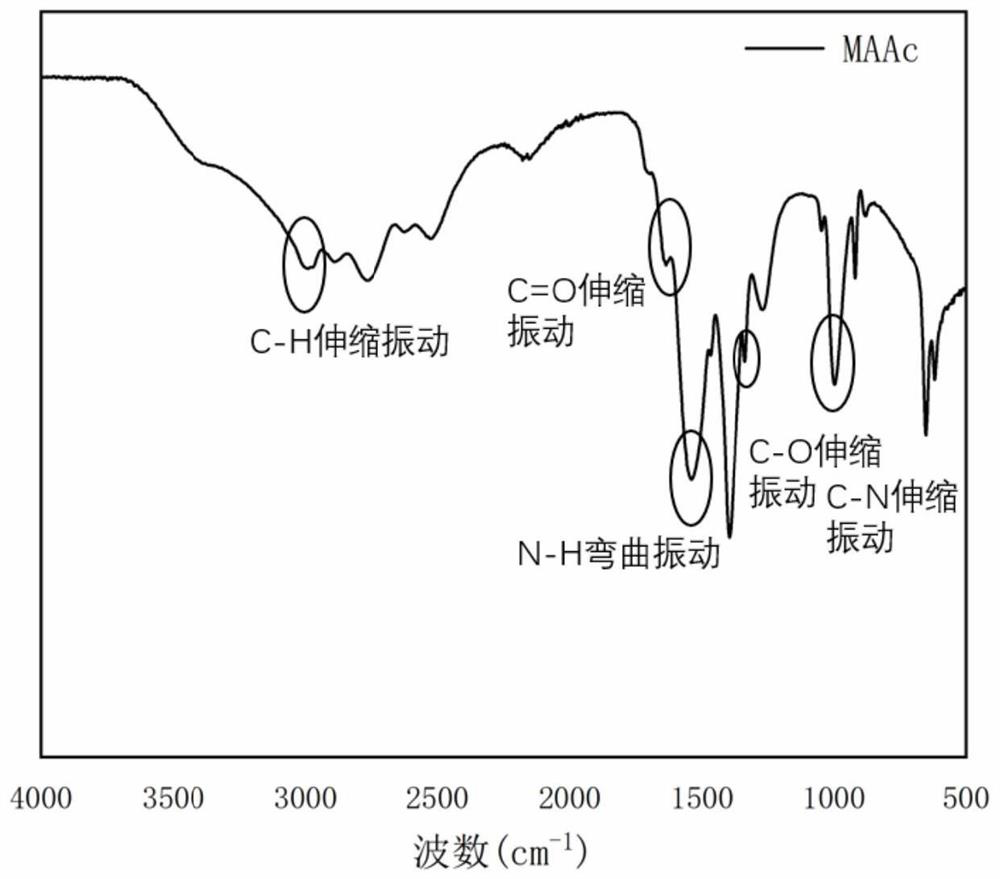

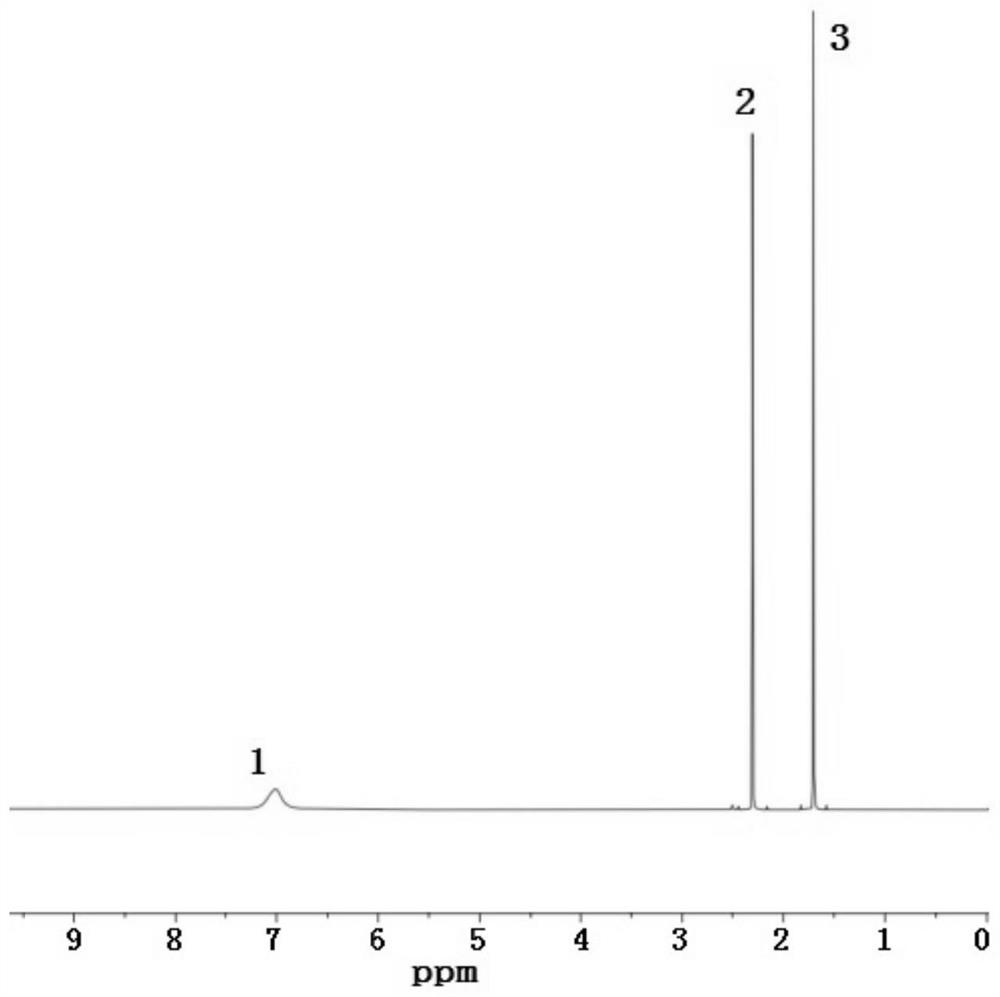

[0034] Step 2: The ionic liquid mixture is subjected to vacuum rotary evaporation for 1.5 h at a temperature of 80° C. and a vacuum degree of -0.15 MPa to obtain meth...

Embodiment 2

[0039] The embodiment of the present invention provides a preparation method of methylamine acetate ionic liquid, and the preparation method comprises the following steps:

[0040] Step 1. Under the stirring condition of the rotating speed of 300rpm, acetic acid was added dropwise to the methylamine methanol solution with a concentration of 15wt% at a speed of 0.8mL / min. The ionic liquid mixture is obtained by intermittently reacting 5 times under the conditions, wherein the conditions of the intermittent reaction are as follows: the microwave irradiation time is 1.5min, the first intermittent time is 2, and the intermittent time of the n+1th time is longer than that of the nth time. 40s, 1≤n≤4; the molar ratio of the above formic acid to methylamine is 1:1.2;

[0041] In step 2, the ionic liquid mixture is subjected to vacuum rotary evaporation for 2 hours under the conditions of temperature of 85° C. and vacuum degree of -0.12 MPa to obtain methylamine acetate ionic liquid M...

Embodiment 3

[0044] The embodiment of the present invention provides a preparation method of methylamine acetate ionic liquid, and the preparation method comprises the following steps:

[0045]Step 1. Under the stirring condition of the rotating speed of 100rpm, acetic acid was added dropwise to the methylamine aqueous solution with a concentration of 15wt% at a speed of 0.5mL / min. The temperature was 5°C, the power was 200W, and the frequency was 2450MHz under microwave conditions The batch reaction is carried out for 6 times to obtain an ionic liquid mixture, wherein the conditions of the batch reaction are: the microwave irradiation time is 2.5min, the first batch time is 3, and the interval time of the n+1th time is 20s longer than that of the nth time. , 1≤n≤5; the molar ratio of the above formic acid and methylamine is 1:1.1;

[0046] In step 2, the ionic liquid mixture is subjected to reduced pressure rotary evaporation for 1 hour under the conditions of a temperature of 75° C. and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com