Preparation method of carrier transport film and preparation method of quantum dot light-emitting diode

A quantum dot luminescence and carrier technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of low carrier mobility, reduce roughness, improve microscopic appearance, film The effect of layer crystallinity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

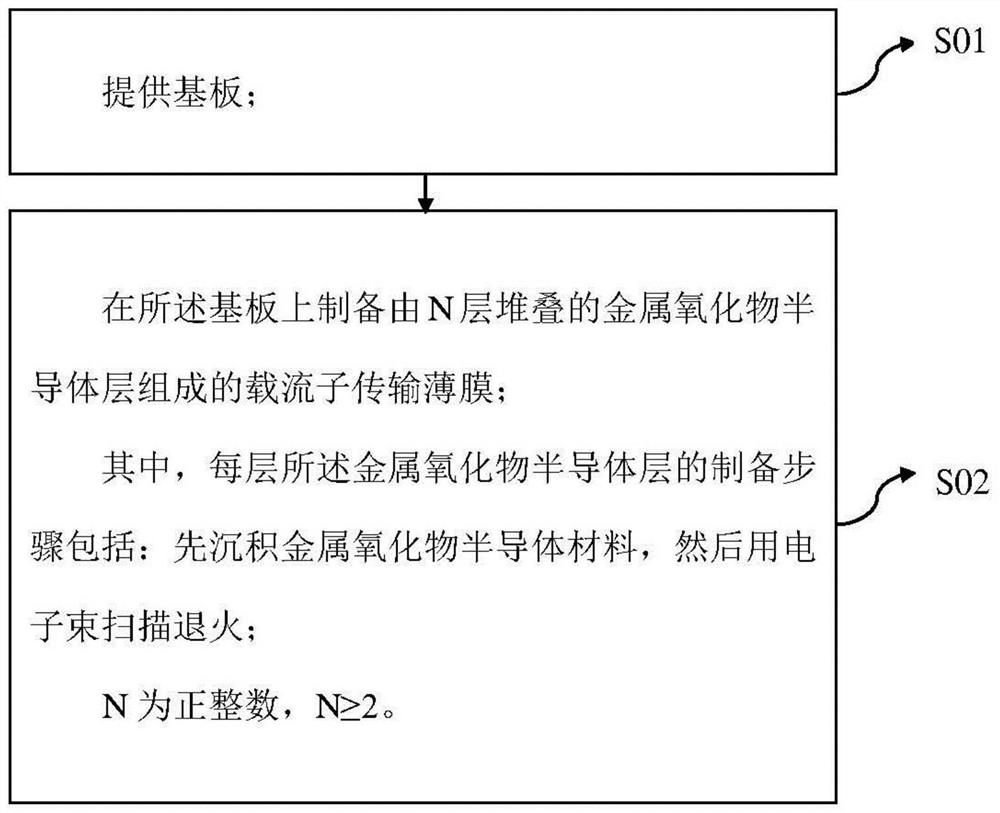

[0028] A first aspect of the embodiments of the present application provides a method for preparing a carrier transport film, such as figure 1 shown, including the following steps:

[0029] S01: Provide substrate;

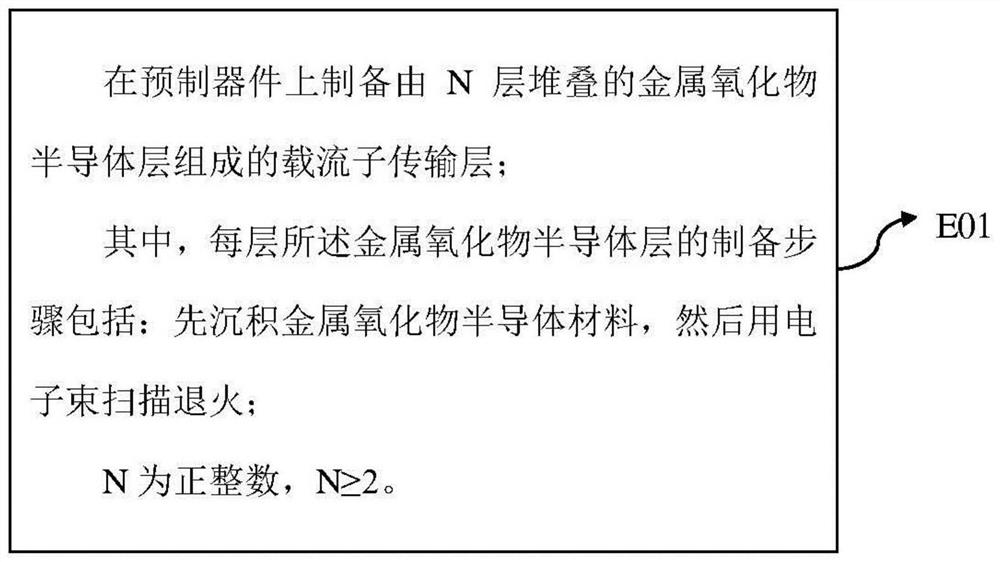

[0030] S02: prepare a carrier transport film composed of N-layer stacked metal oxide semiconductor layers on the substrate;

[0031] Wherein, the preparation steps of each metal oxide semiconductor layer include: first depositing metal oxide semiconductor material, and then scanning annealing with electron beam;

[0032] N is a positive integer, N≥2.

[0033] The preparation method of the carrier transport film provided by the present application adopts the technology of N-layer metal oxide semiconductor layer stacking and layering preparation, that is, each metal oxide semiconductor layer is firstly deposited metal oxide semiconductor material, and then electron beam Scanning annealing; such a preparation method can improve the microscopic morphology of the car...

Embodiment 1

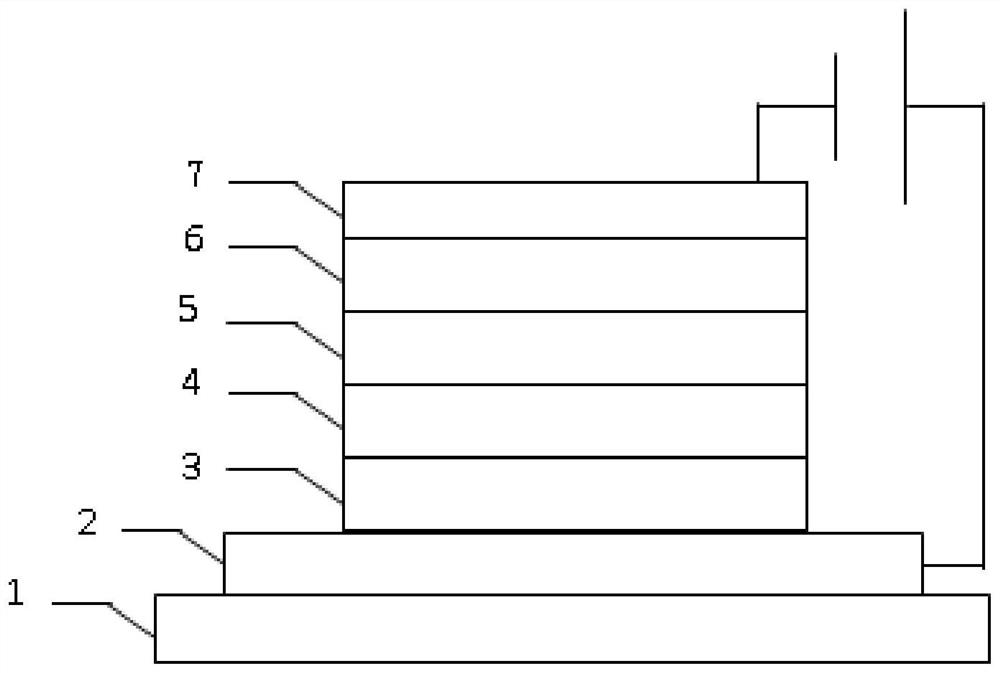

[0090] An upright quantum dot light-emitting diode, from bottom to top, comprises: an ITO substrate (anode), a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, and a cathode. Its preparation process includes the following steps:

[0091] Step S1: on the ITO substrate (anode), spin-coating PEDOT:PSS at a rotational speed of 5000 rpm and a time of 30 seconds, followed by heating at 150° C. for 15 minutes, and standing to cool for 5 minutes to obtain a hole injection layer.

[0092] Step S2: spin-coating TFB (8 mg / mL) on the above hole injection layer with a rotational speed of 3000 rpm and a time of 30 seconds, followed by heating at 80° C. for 10 minutes, and standing to cool for 5 minutes to obtain hole transport Floor.

[0093] Step S3: spin-coating quantum dots (20 mg / mL) on the hole transport layer under the conditions of a rotational speed of 2000 rpm and a time of 30 seconds to obtain a quantum dot light-emitt...

Embodiment 2

[0102] An upright quantum dot light-emitting diode, from bottom to top, comprises: an ITO substrate (anode), a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, and a cathode. Its preparation process includes the following steps:

[0103] Step S1: on the ITO substrate (anode), spin-coating PEDOT:PSS at a rotational speed of 5000 rpm and a time of 30 seconds, followed by heating at 150° C. for 15 minutes, and standing to cool for 5 minutes to obtain a hole injection layer.

[0104] Step S2: spin-coating TFB (8 mg / mL) on the above hole injection layer with a rotational speed of 3000 rpm and a time of 30 seconds, followed by heating at 80° C. for 10 minutes, and standing to cool for 5 minutes to obtain hole transport Floor.

[0105] Step S3: spin-coating quantum dots (20 mg / mL) on the hole transport layer under the conditions of a rotational speed of 2000 rpm and a time of 30 seconds to obtain a quantum dot light-emitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com