Preparation method of nitrogen-doped porous carbon microsphere coated Ni/Co alloy

A nitrogen-doped porous carbon and microsphere technology, applied in the field of alloys, can solve problems such as hindering the large-scale use of precious metal catalysts, scarce platinum-based precious metal reserves, and few active sites, etc., and achieving a multi-level porous structure is beneficial, low in price, and low in cost. The effect of short response times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

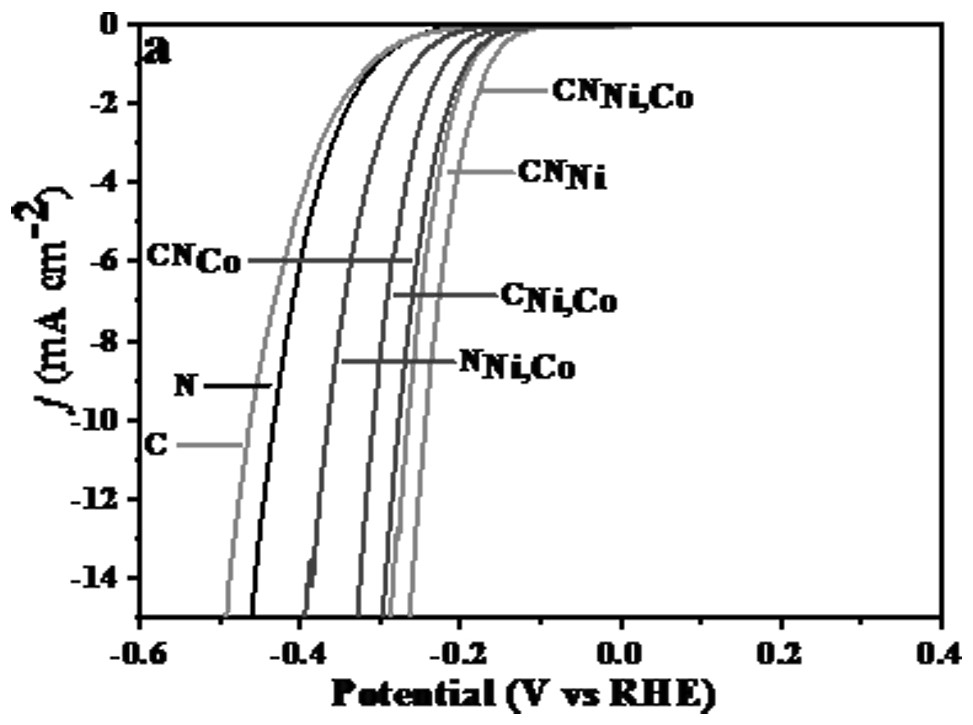

[0038] 1.5 g of pectin, 2.5 g of melamine, 0.582 g of cobalt nitrate, and 0.582 g of nickel nitrate were added to 40 ml of deionized water, heated to 120 °C at a heating rate of 3 °C / min, and hydrothermally heated at a constant temperature for 12 h to obtain a brown intermediate product; Then, under nitrogen atmosphere, the intermediate product was heated to 900 °C at a heating rate of 8 °C / min, and carbonized at constant temperature for 12 h to obtain nitrogen-doped porous carbon microspheres coated Ni / Co alloy, named CN Ni,Co catalyst.

Embodiment 2

[0040] 1.5 g of pectin, 2.5 g of melamine, 0.582 g of cobalt nitrate, and 0.582 g of nickel nitrate were added to 40 ml of deionized water, heated to 100 °C at a heating rate of 5 °C / min, and heated at a constant temperature for 14 h to obtain a brown intermediate product; Then, in a nitrogen atmosphere, the intermediate product was heated to 900°C at a heating rate of 5°C / min, and carbonized at a constant temperature for 12 h to obtain a Ni / Co alloy coated with nitrogen-doped porous carbon microspheres.

Embodiment 3

[0042]1.5 g of pectin, 2.5 g of melamine, 0.582 g of cobalt nitrate, and 0.582 g of nickel nitrate were added to 40 ml of deionized water, heated to 180 °C at a heating rate of 2 °C / min, and hydrothermally heated at a constant temperature for 10 h to obtain a brown intermediate product; Then, under nitrogen atmosphere, the intermediate product was heated to 900 °C at a heating rate of 10 °C / min, and carbonized at constant temperature for 12 h to obtain nitrogen-doped porous carbon microspheres coated Ni / Co alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com