Preparation method of flame retardant dithio pyrophosphate

A technology of dithiopyrophosphate and flame retardant, which is applied in the field of flame retardant, can solve the problems of damage and high cost, and achieve the effects of low cost, stable properties and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

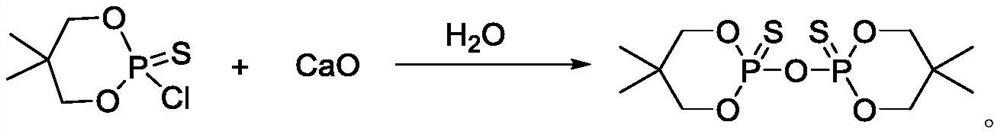

[0030] A method for preparing DDPS, comprising the following experimental steps:

[0031] Weigh 0.368g (2mmol) of DDSP into a 200ml round-bottomed flask, add 50ml of deionized water, stir at room temperature to dissolve it, start adding 0.11g (2mmol) of calcium oxide powder, stir mechanically for 24h, there will be Precipitation was precipitated, and after the reaction was completed, washed with 95% absolute ethanol, filtered and dried to obtain 314 mg of the target compound DDPS. Yield 90.7%.

[0032]

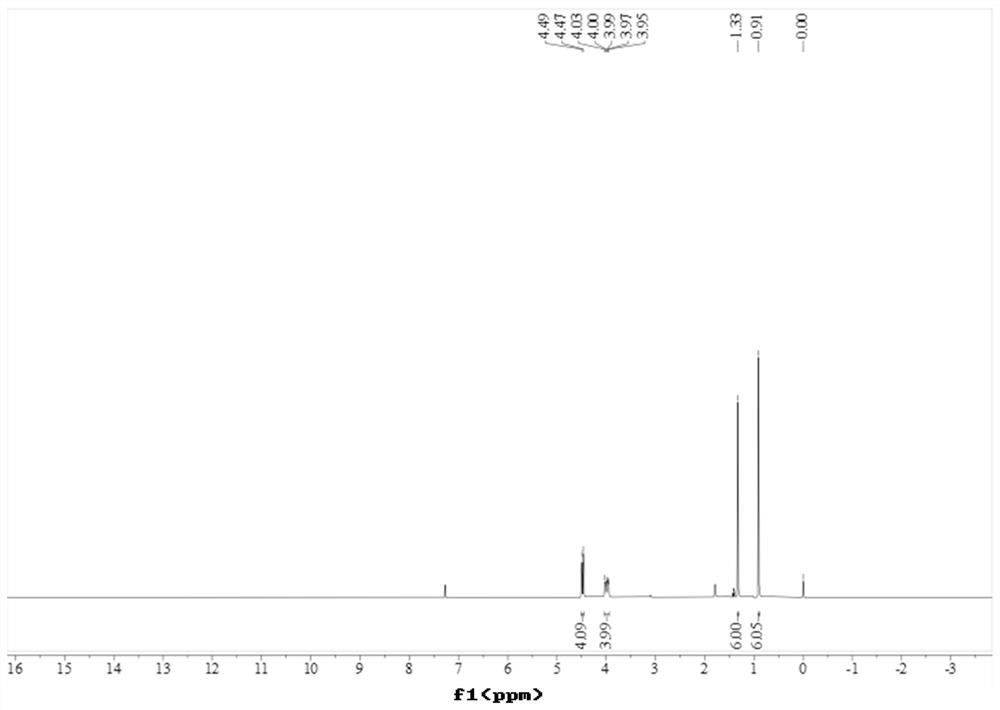

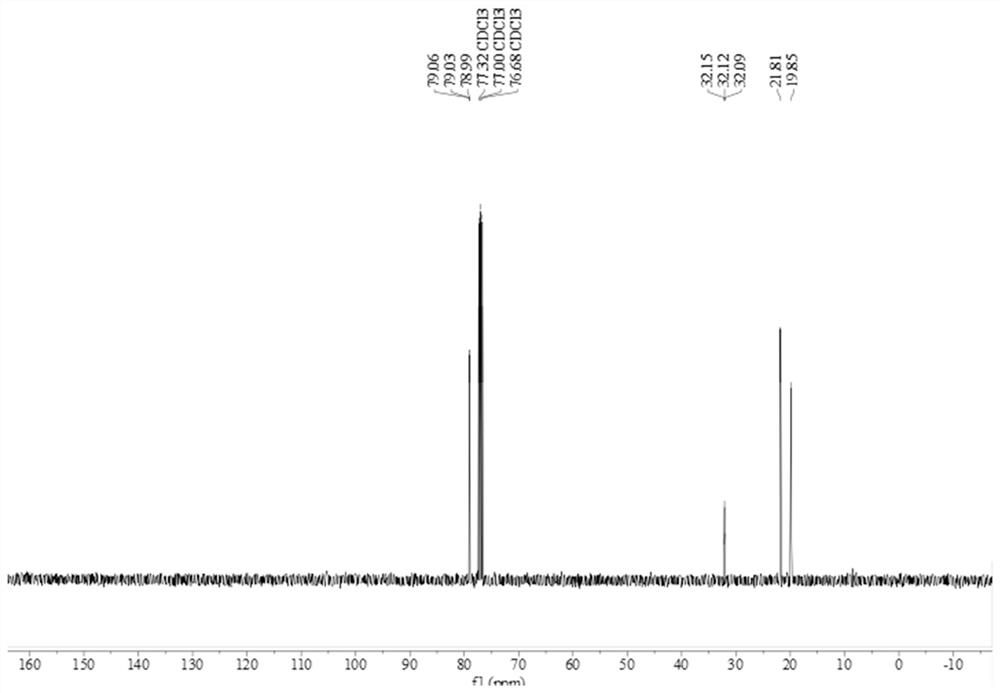

[0033] 1 H NMR (400MHz, CDCl 3 )δ4.48(d,J=10.8Hz,4H),4.04-3.94(m,4H),1.33(s,6H),0.91(s,6H). 13 C NMR (101MHz, CDCl 3 )δ79.06,79.03,78.99,77.32,77.00,76.68,32.15,32.12,32.09,21.81,19.85.

Embodiment 2

[0035] A method for preparing DDPS, a gram-level experiment, comprising the following experimental steps:

[0036] Weigh 1.84g (10mmol) of DDSP into a 500ml round-bottomed flask, add 250ml of deionized water, stir at room temperature to dissolve, start adding 0.56g (10mmol) of calcium oxide powder, stir mechanically for 24h, there will be Precipitation was precipitated, and after the reaction was completed, washed with 95% absolute ethanol, filtered and dried to obtain 1.46 g of the target compound DDPS. Yield 84.4%.

Embodiment 3

[0038] A method for preparing DDPS, the alkali is optimized, comprising the following experimental steps:

[0039] Weigh 0.368g (2mmol) of DDSP into a 200ml round-bottomed flask, add 50ml of deionized water, stir at room temperature to dissolve it, start adding 0.224g (2mmol) of potassium tert-butoxide, stir mechanically for 24h, after the reaction is completed, use Washed with 95% absolute ethanol, filtered and dried to obtain 0.138 g of the target compound DDPS. Yield 40%.

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com