Positive electrode material for improving cycling stability of sulfurized polyacrylonitrile battery and preparation method of positive electrode material

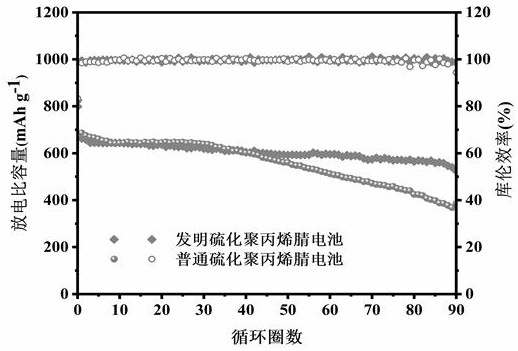

A technology of polyacrylonitrile battery and vulcanized polyacrylonitrile, which is applied in battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problems of low utilization rate of sulfur, achieve increased reaction kinetics, scientific and reasonable design, reduce The effect of the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of vulcanized polyacrylonitrile cathode material

[0036] Accurately weigh 5.0 g of elemental sulfur, 1.0 g of polyacrylonitrile, and 0.05 g of lithium iodide, and grind them by hand in an agate mortar for 15 minutes until there are no large polyacrylonitrile particles visible to the naked eye. The uniformly ground powder was dried in an oven at 60°C for 2 hours to remove excess water.

[0037] The operation was carried out in a glove box filled with argon gas, the above-mentioned powder was placed in a quartz tube and then placed in a reaction kettle, the reaction kettle was tightened, and the reaction kettle was placed in a tube furnace filled with argon gas for heating. The temperature range of the heating process was as follows: From room temperature to 400°C, the heating rate is 5°C / min, the temperature is kept at 400°C for 6 hours, and the temperature is naturally cooled to room temperature after the heat preservation process. After taking out the...

Embodiment 2

[0046] (1) Accurately weigh 3.0 g of elemental sulfur, 1.0 g of polyacrylonitrile, and 0.15 g of lithium iodide, and grind them by hand in an agate mortar for 20 minutes until there are no large polyacrylonitrile particles visible to the naked eye. The uniformly ground powder was dried in an oven at 60°C for 3 hours to remove excess water.

[0047] The operation was carried out in a glove box filled with argon gas, the above-mentioned powder was placed in a quartz tube and then placed in a reaction kettle, the reaction kettle was tightened, and the reaction kettle was placed in a tube furnace filled with argon gas for heating. The temperature range of the heating process was as follows: From room temperature to 400°C, the heating rate is 7°C / min, and the temperature is kept at 400°C for 7 hours, and the temperature is naturally cooled to room temperature after the heat preservation process. After taking out the black powder, continue grinding in an agate mortar for 15 minutes,...

Embodiment 3

[0055] Accurately weigh 4.0 g of elemental sulfur, 1.0 g of polyacrylonitrile, and 0.1 g of lithium iodide, and grind them by hand in an agate mortar for 30 minutes until there are no large polyacrylonitrile particles visible to the naked eye. The uniformly ground powder was dried in an oven at 60°C for 5 hours to remove excess water.

[0056] The operation was carried out in a glove box filled with argon gas, the above powder was placed in a quartz tube and then placed in a reaction kettle, the reaction kettle was tightened, and the reaction kettle was placed in a tube furnace filled with argon gas for heating. The temperature range of the heating process was as follows: From room temperature to 400°C, the heating rate is 10°C / min, the temperature is kept at 400°C for 8 hours, and the temperature is naturally cooled to room temperature after the heat preservation process. After taking out the black powder, continue grinding in an agate mortar for 15 minutes, place it in a dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com