Synthesis method of trimethylolpropane polyoxypropylene ether

A technology of trimethylolpropane polyoxypropylene ether and methylolpropane polyoxypropylene ether, which is applied in the field of synthesis of trimethylolpropane polyoxypropylene ether, can solve inactivation, long induction period and complex production process and other problems, to achieve the effect of low consumption, stable product quality and simple separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

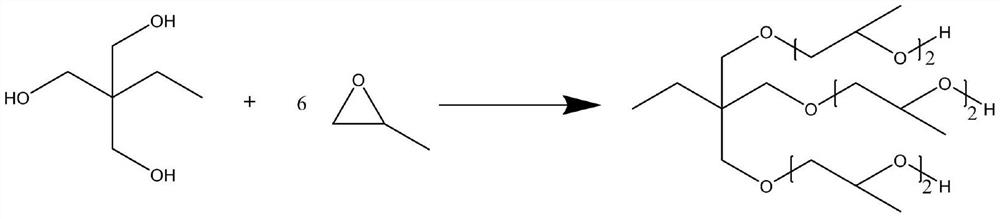

Method used

Image

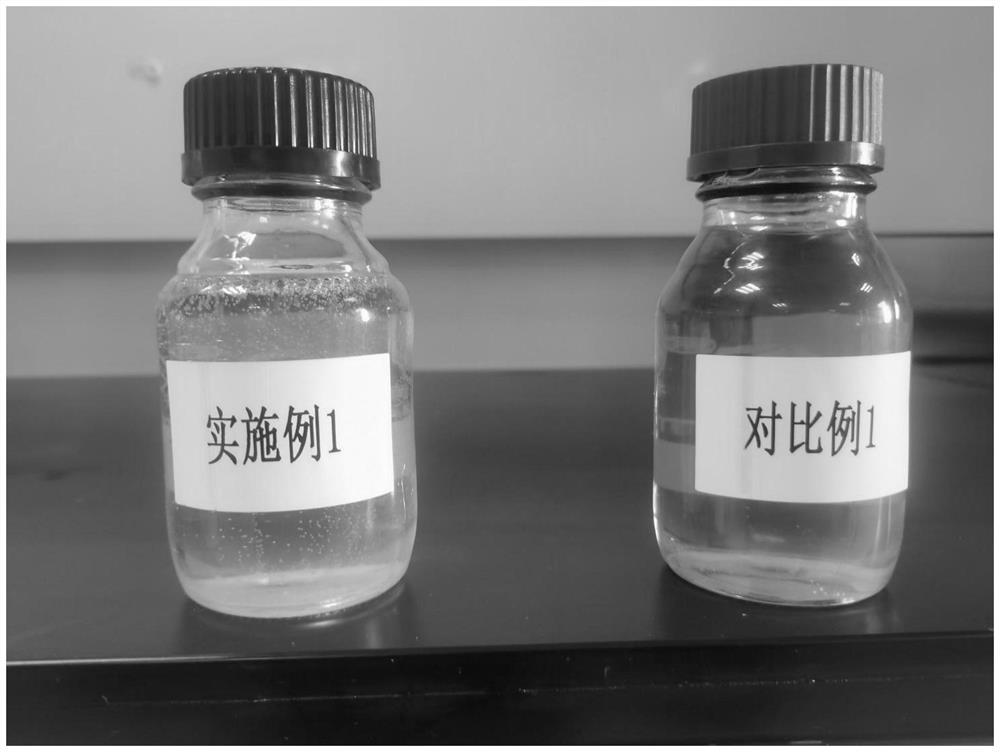

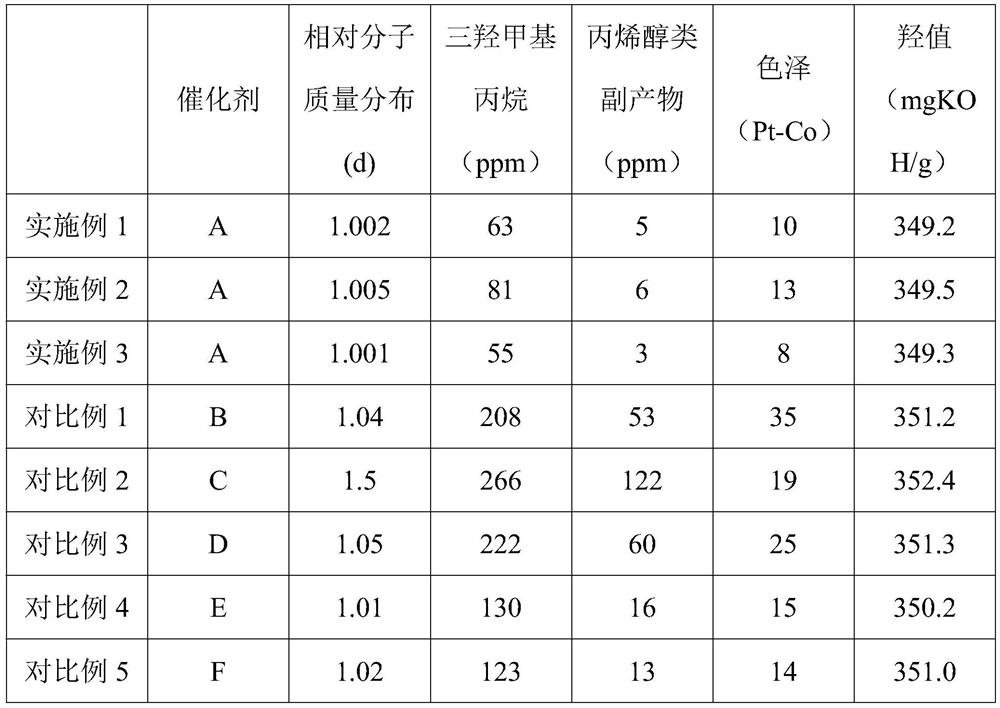

Examples

Embodiment 1

[0031] The present embodiment provides a method for synthesizing trimethylolpropane polyoxypropylene ether, and the specific steps are as follows:

[0032] Weigh trimethylolpropane 584g, ETS-101.05g (0.05%), put it into the reactor after mixing, and after vacuuming, replace nitrogen in the reactor, replace nitrogen three times, vacuumize after the last replacement, and put it in a vacuum Under the condition of temperature ≥-0.098MPa, heat the reaction kettle to melt the material completely, continuously feed 1513g of propylene oxide, control the reaction temperature at 100±2℃, and the pressure in the reaction kettle ≤0.35Mpa. After adding, keep the temperature and continue the reaction. Until the system pressure in the reaction kettle no longer drops. After the reaction, the reaction mixture was filtered, cooled to 75°C, and the unreacted propylene oxide was removed in vacuo to obtain the finished product. The results of liquid chromatography analysis: the content of propenyl...

Embodiment 2

[0034] The present embodiment provides a method for synthesizing trimethylolpropane polyoxypropylene ether, and the specific steps are as follows:

[0035] Weigh trimethylolpropane 584g, ETS-100.63g (0.03%), put it into the reactor after mixing, and after vacuuming, replace nitrogen in the reactor, replace nitrogen three times, vacuumize after the last replacement, and put it in a vacuum Under the condition of temperature ≥-0.098MPa, heat the reaction kettle to melt the material completely, continuously feed 1513g of propylene oxide, control the reaction temperature at 100±2℃, and the pressure in the reaction kettle ≤0.35Mpa. After adding, keep the temperature and continue the reaction. Until the system pressure in the reaction kettle no longer drops. After the reaction, the reaction mixture was filtered, cooled to 75°C, and the unreacted propylene oxide was removed in vacuo to obtain the finished product. The results of liquid chromatography analysis: the content of propenyl...

Embodiment 3

[0037] The present embodiment provides a method for synthesizing trimethylolpropane polyoxypropylene ether, and the specific steps are as follows:

[0038]Weigh trimethylolpropane 584g, ETS-101.68g (0.08%), put it into the reactor after mixing, and after vacuuming, replace nitrogen in the reactor, replace nitrogen three times, vacuumize after the last replacement, and put it in a vacuum Under the condition of temperature ≥-0.098MPa, heat the reaction kettle to melt the material completely, continuously feed 1513g of propylene oxide, control the reaction temperature at 100±2℃, and the pressure in the reaction kettle ≤0.35Mpa. After adding, keep the temperature and continue the reaction. Until the system pressure in the reaction kettle no longer drops. After the reaction, the reaction mixture was filtered, cooled to 75°C, and the unreacted propylene oxide was removed in vacuo to obtain the finished product. Liquid chromatography analysis results: the content of propenyl alcohol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com