Electret and printing method thereof

A technology of electret and polar sheet, which is applied in the field of electret and its printing, can solve problems such as uneven charge distribution, and achieve the effects of reducing preparation costs, excellent electrical properties, and excellent piezoelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

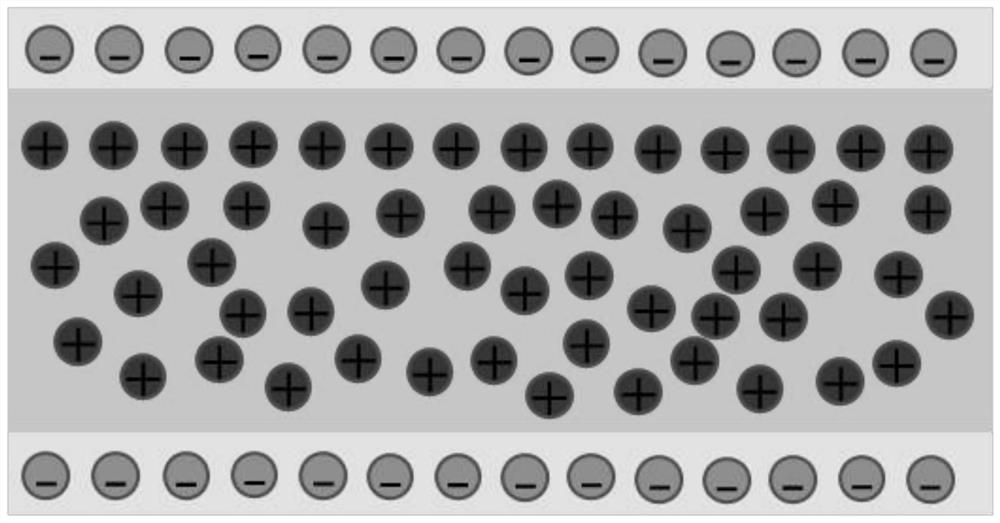

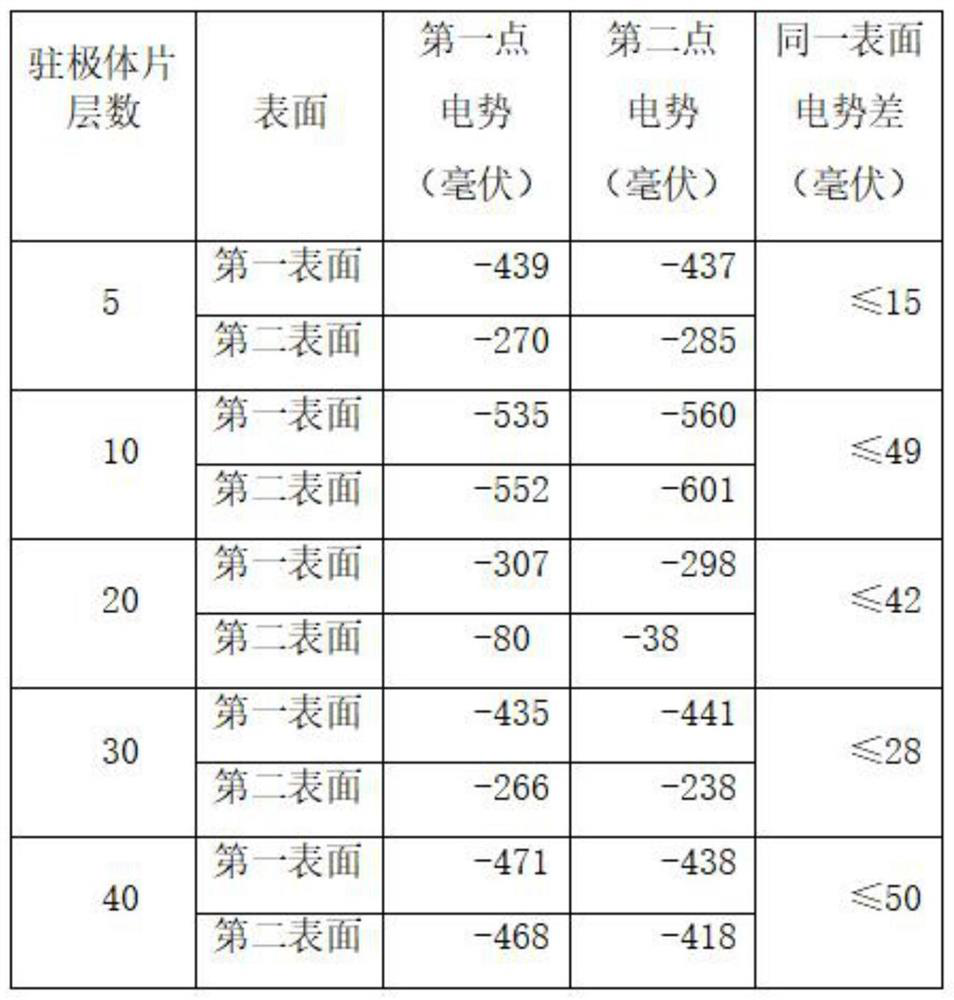

[0039] The electret provided in this embodiment includes a substrate and a multilayer electret sheet printed on the substrate. The electret is in the form of a sheet, and the potential difference between any two points on the same surface of the electret is not greater than 50 milliseconds. Volts; the thickness difference at different positions of the electret is not more than 15 microns. Electret Structure Reference figure 1 shown, it is a flexible electret.

[0040] The preparation material of the electret includes a polymer dielectric material, an organic solvent, and acetone. The mass fraction of the polymer dielectric material is 8%-14%, the mass fraction of the organic solvent is 40%-70%, and the mass fraction of acetone is 32%-56%; the preparation materials can also include two-dimensional materials, the two-dimensional materials are graphene, carbon nanotubes, piezoelectric ceramics, etc., and the mass fraction of the two-dimensional materials is 0.01%-0.05%; used to ...

Embodiment 2

[0053] The electret printing method provided by this embodiment includes the following steps:

[0054] S1, configure printing ink;

[0055] The printing ink includes polymer dielectric material, organic solvent and acetone, and the mass fraction of polymer dielectric material is 8%-

[0056] 14%, the mass fraction of organic solvent is 40%-70%, and the mass fraction of acetone is 32%-56%;

[0057] After mixing, heat at 40-60°C for 2-5 hours;

[0058] The polymer dielectric material is polyvinylidene fluoride, a copolymer of vinylidene fluoride or trifluoroethylene; the organic solvent is dimethylformamide or N-methylpyrrolidone.

[0059] S2. Lay out the substrate to print layer by layer, and inject electric charge during printing to make the electric charge enter the electret body;

[0060] The printing voltage is controlled to be 2-5kV, the substrate temperature is 40-80℃, the flow rate of the propelling pump is 0-2ml / h, and the models of the printing needles are needles #...

Embodiment 3

[0081] The difference between this embodiment and the second embodiment is that the printing ink also includes two-dimensional materials. The two-dimensional materials are graphene, carbon nanotubes, piezoelectric ceramics, etc., and the mass fraction of the two-dimensional materials is 0.01%-0.05%; The internal charge density distribution and stability of the electret material affects the crystallization, grain size and phase transition of the material, thereby improving the stability of the electret.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com